Count me in! My case arrived yesterday as well and I'm excited to start building it out.Would people be interested in a group buy (at cost) for clear resin version of these adjustment knobs? it looks like I could get them for around $3 each if I ordered 10.

3D Printing & MacEffects Appreciation

- Thread starter wottle

- Start date

-

- Tags

- maceffects

-

Please can you read through and vote on the following proposition for changes to the board structure by clicking here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OK, I'll post here an update when the sample pair arrive. If they work, I'll place an order for a handful more for people who are interested. I just didn't want to order a bunch in case there were fitment issues.Count me in! My case arrived yesterday as well and I'm excited to start building it out.

I may be going overboard with this clear stuff. I made an updated version of this mount that I'm going to order in clear resin as well. Not really much value in doing a group buy on this one because I can only order one at a time and still get the cheaper shipping. If you wanted to do the same, it would be cheaper for each person to order their own and not have to pay twice for shipping.

Heres the link to my version for resin printing if others want to print it. I've not printed clear resin this thick, so it will be interesting to see how it turns out. I'll adjust if I get mine in and it does not look good.

FYI, For me to get it printed in transparent resin and shipped to the US, it cost $18.12. I'll post pictures of it and the clear knob when they arrive.

Heres the link to my version for resin printing if others want to print it. I've not printed clear resin this thick, so it will be interesting to see how it turns out. I'll adjust if I get mine in and it does not look good.

FYI, For me to get it printed in transparent resin and shipped to the US, it cost $18.12. I'll post pictures of it and the clear knob when they arrive.

A few PCB manufactures do full color PCBs now(Both JLC and PCBWay do, probably others too)@wottle

Sorry if I've overlooked the answer in this thread, but how did you get that rainbow-colored PCB made?

As of september year they had different processes for ordering, not sure if it's changed at all for either of them since then

JLC you had to use their EasyEDA Pro software to design the PCB(or import a project from another EDA and double check your work to make sure it didn't mess anything up) and import the image for the silkscreen, and export it a certain way

PCBWay you submitted the gerber files in the regular way, and then send them the image of what you want on the board.

(example courtesy of @GutBomb , EricSCSI)

we've come a long way from hand-drawn tracings and a crock pot full of acid etch.

Last edited:

Yeah, @tom_B has a much better understanding of the process than me. But much like I fumbled my way through the PCB design process, I stumbled my way through the full color PCB process. I only did it because JLCPCB had a coupon that made it almost free to do, so I read a guide, and used EasyEDA Pro to import my PCB from EAGLE, then overlay the rainbow image. You then have to export from EasyEDA to JLCPCB for ordering.A few PCB manufactures do full color PCBs now(Both JLC and PCBWay do, probably others too)

As of september year they had different processes for ordering, not sure if it's changed at all for either of them since then

JLC you had to use their EasyEDA Pro software to design the PCB(or import a project from another EDA and double check your work to make sure it didn't mess anything up) and import the image for the silkscreen, and export it a certain way

PCBWay you submitted the gerber files in the regular way, and then send them the image of what you want on the board.

(example courtesy of @GutBomb , EricSCSI)

View attachment 21941

my $110 PCBWAY quote turned into $300 with shipping and customs (tarrifs). they might have to wait. i'll check others though.I highly recommend trying clear resin prints if you want to match the clear MacEffects case.

Yeah. PcBWay was much more expensive BEFORE the tariffs. Give JLC3DP a try. My guess is it will be 1/2 to 1/4 of the PCBWay cost.

They advertise a lot, whereas JLC hasn't done really any advertising that I've seen. Not only do I see PCBWay everywhere on YouTube, but they have approached me twice by email. Once was a couple years ago when I told them the MOQ of 5pcs was a bit hard to swallow for the average vintage computer hobbyist. They did a follow-up with me last week. I've not responded back because, hey, I don't even let YouTube show ads on my channel, so why would I do 30 second spots?PcBWay was much more expensive BEFORE the tariffs.

With that said, PCBWay aren't a bad company by any means, and I've seen comparisons between their 3D printed transparent parts and JLC, and PCBway was the winner (based on photos I saw). It all comes down to which ends up with a better print and then for how much. As others have said, even before tariffs there was a rather large pricing difference between PCBWay and JLC.

i have zero problem with PCB's quoted prices for what i wanted to order, it's just the shipping and customs charges that are killing it right now.

i ran my list through JLC, the quote was about half, but they still wanted $150 for S&C, on $60 worth of parts.

then just for fun i looked at Xometry and Protolabs. Holy Jesus! they wanted more for one part than PCB wanted for the whole shipment.

i'll just put it together with the filament parts i already have and get the really clear stuff later.

i ran my list through JLC, the quote was about half, but they still wanted $150 for S&C, on $60 worth of parts.

then just for fun i looked at Xometry and Protolabs. Holy Jesus! they wanted more for one part than PCB wanted for the whole shipment.

i'll just put it together with the filament parts i already have and get the really clear stuff later.

i have zero problem with PCB's quoted prices for what i wanted to order, it's just the shipping and customs charges that are killing it right now.

i ran my list through JLC, the quote was about half, but they still wanted $150 for S&C, on $60 worth of parts.

then just for fun i looked at Xometry and Protolabs. Holy Jesus! they wanted more for one part than PCB wanted for the whole shipment.

i'll just put it together with the filament parts i already have and get the really clear stuff later.

Can you share the STLs for the parts? I’m curious why the shipping was so high? I wonder if it’s because I have mostly only done small parts that can ship easily.

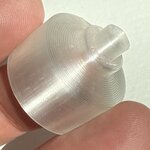

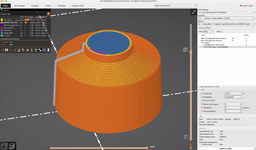

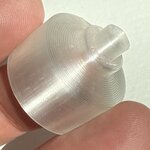

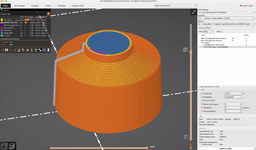

Getting closer to reshelling my SE/30. . . Printed my version of the brightness knob, finally:

Clarity isn’t perfect obviously with FDM printing, especially with something this thick. Early on I had a hell of a time printing with this, but eventually dialed in great settings for printing on my Prusa Mini+. A few tips I picked up when trying to print ”light pipes” for LEDs in clear filament:

1. Reduce the amount of directional cross-hatching by aligning layers to print the same direction every time. In this case, because the object is round, I am using a 100% infill, concentric pattern achieved by bumping up perimeters to 8 which basically eliminates the infill setting and keeps the nozzle moving in circles the whole way (with one exception below).

--Note that while this may not be crystal clear, it’s a much nicer effect than you would get from a grid-like monotonic infill that alternates 90 degrees every layer! All of that cross-hatching will result in tiny overlapping air gaps which scatter the light. Aligning the nozzle direction every layer helps reduce that.

2. Thicker layers are better here. If this was a single-walled vase-mode print, thin layers may work to your advantage, but the knob needs to be strong and rigid. In this case, thicker layers will put down bigger filament “tubes” to permit the light vs. lots of thin layers that might have more air gaps between them scattering light. YMMV, of course, but I find with thick stuff, a .2mm layer height has better clairty than thinner.

3. Get your temps right. For Taulman T-Glase which this is, I find 220C to be the right temp to avoid scorching and to get good layer adhesion, and 330 for the first layer to compress and stick nicely to the bed. Running the fan is also recommended. I run it at 40% after the first few layers.

4. Be mindful of overhangs (this model). My model prints in two parts to avoid supports. The knob itself prints with the post end up, slowly coning to the center. However, there is a moment after printing the keyed hole for the post that it needs to print a small bridging layer. If you adjusted your model to use 8 perimeters to get perfect concentric infill as recommended above, check the first bridging layer at 19mm. For me, the slicer created circles in thin air for that are supposed to bridge—but they wont. This would have been a disaster since the filament would just dangle down the middle and probably booger up the point that needs some precision where the post will go. To correct this, I added a modifier at 18.8-19.0mm to change to 2 perimeters. The slicer took the cue to draw simple, straight bridge lines and cross-hatched this area for two more layers for perfect bridging. This is directly under the pin and over the post that will be glued anyway, so not a concern for transparency. The concentric areas everywhere else are maintained.

This stuff is apparently PETT, a close cousin to PETG. It’s really tough stuff, It sticks great to PEI beds, and you can wet sand the seams and polish with fingernail buffing tools if you like. If you print this filament at 240, it gets all goopy and the pin sags into the center. At 220 it is beautiful.

Resin would be better, but I will be very happy with this I think.

Clarity isn’t perfect obviously with FDM printing, especially with something this thick. Early on I had a hell of a time printing with this, but eventually dialed in great settings for printing on my Prusa Mini+. A few tips I picked up when trying to print ”light pipes” for LEDs in clear filament:

1. Reduce the amount of directional cross-hatching by aligning layers to print the same direction every time. In this case, because the object is round, I am using a 100% infill, concentric pattern achieved by bumping up perimeters to 8 which basically eliminates the infill setting and keeps the nozzle moving in circles the whole way (with one exception below).

--Note that while this may not be crystal clear, it’s a much nicer effect than you would get from a grid-like monotonic infill that alternates 90 degrees every layer! All of that cross-hatching will result in tiny overlapping air gaps which scatter the light. Aligning the nozzle direction every layer helps reduce that.

2. Thicker layers are better here. If this was a single-walled vase-mode print, thin layers may work to your advantage, but the knob needs to be strong and rigid. In this case, thicker layers will put down bigger filament “tubes” to permit the light vs. lots of thin layers that might have more air gaps between them scattering light. YMMV, of course, but I find with thick stuff, a .2mm layer height has better clairty than thinner.

3. Get your temps right. For Taulman T-Glase which this is, I find 220C to be the right temp to avoid scorching and to get good layer adhesion, and 330 for the first layer to compress and stick nicely to the bed. Running the fan is also recommended. I run it at 40% after the first few layers.

4. Be mindful of overhangs (this model). My model prints in two parts to avoid supports. The knob itself prints with the post end up, slowly coning to the center. However, there is a moment after printing the keyed hole for the post that it needs to print a small bridging layer. If you adjusted your model to use 8 perimeters to get perfect concentric infill as recommended above, check the first bridging layer at 19mm. For me, the slicer created circles in thin air for that are supposed to bridge—but they wont. This would have been a disaster since the filament would just dangle down the middle and probably booger up the point that needs some precision where the post will go. To correct this, I added a modifier at 18.8-19.0mm to change to 2 perimeters. The slicer took the cue to draw simple, straight bridge lines and cross-hatched this area for two more layers for perfect bridging. This is directly under the pin and over the post that will be glued anyway, so not a concern for transparency. The concentric areas everywhere else are maintained.

This stuff is apparently PETT, a close cousin to PETG. It’s really tough stuff, It sticks great to PEI beds, and you can wet sand the seams and polish with fingernail buffing tools if you like. If you print this filament at 240, it gets all goopy and the pin sags into the center. At 220 it is beautiful.

Resin would be better, but I will be very happy with this I think.

Last edited:

For those planning to print a knob, I just updated the .STL file here. More than 3 years ago when I knocked this model together in TinkerCAD, the cone and cylinder shapes had a much lower maximum sides. Today you can bump up the sides to make things perfectly round at this scale. So, I refactored the original from its constituent parts and pushed the sides to the max. Sorry, I should have improved the resolution earlier.

You may never even notice the sides if you already printed. I am not going to reprint mine. Heck, it‘s maybe even nice to have some tactile grip, but it should be smooth to match the original.

You may never even notice the sides if you already printed. I am not going to reprint mine. Heck, it‘s maybe even nice to have some tactile grip, but it should be smooth to match the original.

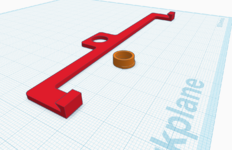

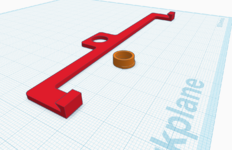

After watching the recent JDW video featuring the SE/30 color LCD conversion, I decided I needed the chassis feet that cover the metal and prevent desk scratches, (only in my case, MacEffects clear case scratches). Naturally, I will print the feet in clear filament, but then I noticed the original model has small overhangs.

This might not be a big issue, but I don’t want to take chances with my clear filament which is already a bit tricky to dial-in, so decided to do a remix here.

My version of the feet changed the overhangs to 45-degree slopes which should hopefully be enough to keep them in position. Then I noticed the tube part which holds the feet bracket in place also has an overhanging lip. Even though it’s just under a millimeter or so, I am not going to risk it. I cut the tube part out of the model so it can be printed upside-down separately and snapped back into place (and a drop of glue?).

I have not printed it yet but wanted to share with others in case “chassis scratchy” is a shared concern.

ALSO: you need to mirror the part in your slicer. I noticed the original right and left are just flipped versions, but I only worked over one of them. It’s not symmetrical in both axes, so I don’t think you can just print two and swing one around. You gotta mirror it first. The tube plugs are probably fine though.

This might not be a big issue, but I don’t want to take chances with my clear filament which is already a bit tricky to dial-in, so decided to do a remix here.

My version of the feet changed the overhangs to 45-degree slopes which should hopefully be enough to keep them in position. Then I noticed the tube part which holds the feet bracket in place also has an overhanging lip. Even though it’s just under a millimeter or so, I am not going to risk it. I cut the tube part out of the model so it can be printed upside-down separately and snapped back into place (and a drop of glue?).

I have not printed it yet but wanted to share with others in case “chassis scratchy” is a shared concern.

ALSO: you need to mirror the part in your slicer. I noticed the original right and left are just flipped versions, but I only worked over one of them. It’s not symmetrical in both axes, so I don’t think you can just print two and swing one around. You gotta mirror it first. The tube plugs are probably fine though.

Looking forward to hearing back from you after it has been printed and tested....decided to do a remix here.

View attachment 22175

I have not printed it yet but wanted to share with others in case “chassis scratchy” is a shared concern.

The original feet are here. I had issues getting aeberbach's original STL file printed at JLC3DP because it was a single file with two parts needing printing, which is a big no-no at JLC3DP:

So I contacted him and asked if he could put each foot into a separate STL file, which he kindly did:

That's important for folks like me who don't have a 3D printer and need to use services like JLC.

I printed mine in Nylon because it's not only cheaper than FDM printing at JLC, but JLC frustratingly won't print in FDM unless the part printed is rather enormous. So if I ultimately print your version feet (which I will decide after hearing your feedback after you print them), I would likely need to get them printed in Nylon as well. But if you could make both a separate Left and Right, that would be great for JLC. And assuming your cylinder is the same for both feet, then there would be a total of 3 separate STL files needed for printing at JLC.

In regards to your brightness knob...

You've nicely put the two required pieces into separate STL files, so this will be great for printing at JLC. Sadly, the size is too small for JLC to print in PLA, forcing me back to Nylon again. But Nylon is a bit stretchy and quite durable, so other than being a bit rough to the touch, it should be OK.

I've been thinking about a 3D printed replacement knob because I'd rather keep my SE/30's Analog Board intact, instead of removing its parts for use with my @zigzagjoe LCD Retrofit Kit.

Still trying to figure out the best POT to use. The ZZJ Brightness Knob Guide mentions this Bourns POT, which has a 20mm long Shaft of a "flatted" form factor...

But paying $15 for shipping to Japan only for a single POT is excessive, so I am thinking about this one from AliExpress.

So if that 3D printed brightness knob "in Nylon" will be a good match for the stock knob, then maybe all will work out well in the end.

Done. I should have considered not everyone who wants this would go through the slicing process themselves. This is a good reminder.But if you could make both a separate Left and Right

I will try printing tomorrow. Once I get them fitted I will add another image to the printables item.

As for separate STLs, this is trivially easy and pretty typical, though it is also common to print two objects at once. That’s up to whomever is printing, as there are always risks that an object comes unstuck from the bed or some other problem that could ruin both which is why one should always provide separate files. Slicers and CAD software lets you split things easily. TinkerCAD is great for that and has a super low learning curve (also free). I use my iPad.

On a related note, I see Branchus Creations is doing a tutorial series for Onshape. It looks a lot more capable than TinkerCAD, but maybe not as complex as Fusion.

Will JLC print the knob in resin? The only reason my model for the knob is two parts is to eliminate overhang issues for FDM, although a careful placement of supports might be fine. A resin knob would be ideal, but you’d want to use a combined knob-post version of the model. I just added that to my thingiverse item.So if that 3D printed brightness knob "in Nylon" will be a good match for the stock knob, then maybe all will work out well in the end.

Given the option is there to use an external pot, I would ABSOLUTELY want to do that! Mounting may be tricky though. Once you have the pot in hand, you can probably fabricate something out of a strip of aluminum bent into position from a nearby chassis screw to get the knob into the front case hole. A 3D printed ”pot holder” would be nice for that!