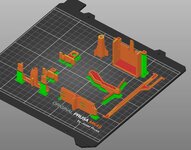

Since I was going to fix 3 of these Powermac G3 beige PC's, I though I might as well draw up all the plastic parts I can print on my Prusa MK4S

Thus i drew up, printed and tested and adjusted and re-printed the following parts:

Print with 0.4mm nozzle at 0.1mm layer height with supports everywhere, and snap them right in place when done!

Thus i drew up, printed and tested and adjusted and re-printed the following parts:

- Slide lock for internal swivel chassis

- motherboard support hook

- motherboard latch

- support column for swivel chassis support

- support strut for chassis

- support stand for swivel chassis

- support stand for power switch

- power switch knob assy

- HDD/ZIPdrive tray

- HDD tray receptacle (snaps in to steel frame)

- CD drive tray

Print with 0.4mm nozzle at 0.1mm layer height with supports everywhere, and snap them right in place when done!