The keys on my Apple IIc A2S4000 keyboard were very stiff, to the point where some had to be pressed really hard to get a click. The other problem is the keys with a latch (ex. Caps Lock) get stuck. We'll go over how we can fix both of these issues.

First, this fix only applies to the following keys. The keyboard PCB is by Photocircuits Atlanta with part 820 0108 03 and copyright date ©1983 printed on the back.

Fortunately, you don't need to desolder the key to fix the stiffness issue of the main keys. The issue is caused by a bend metal clip, which is easily accessible.

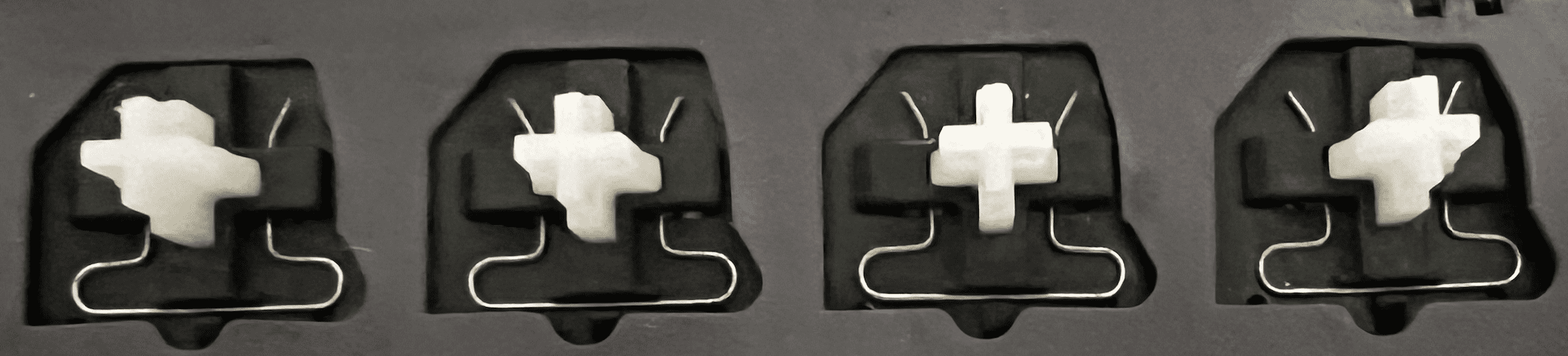

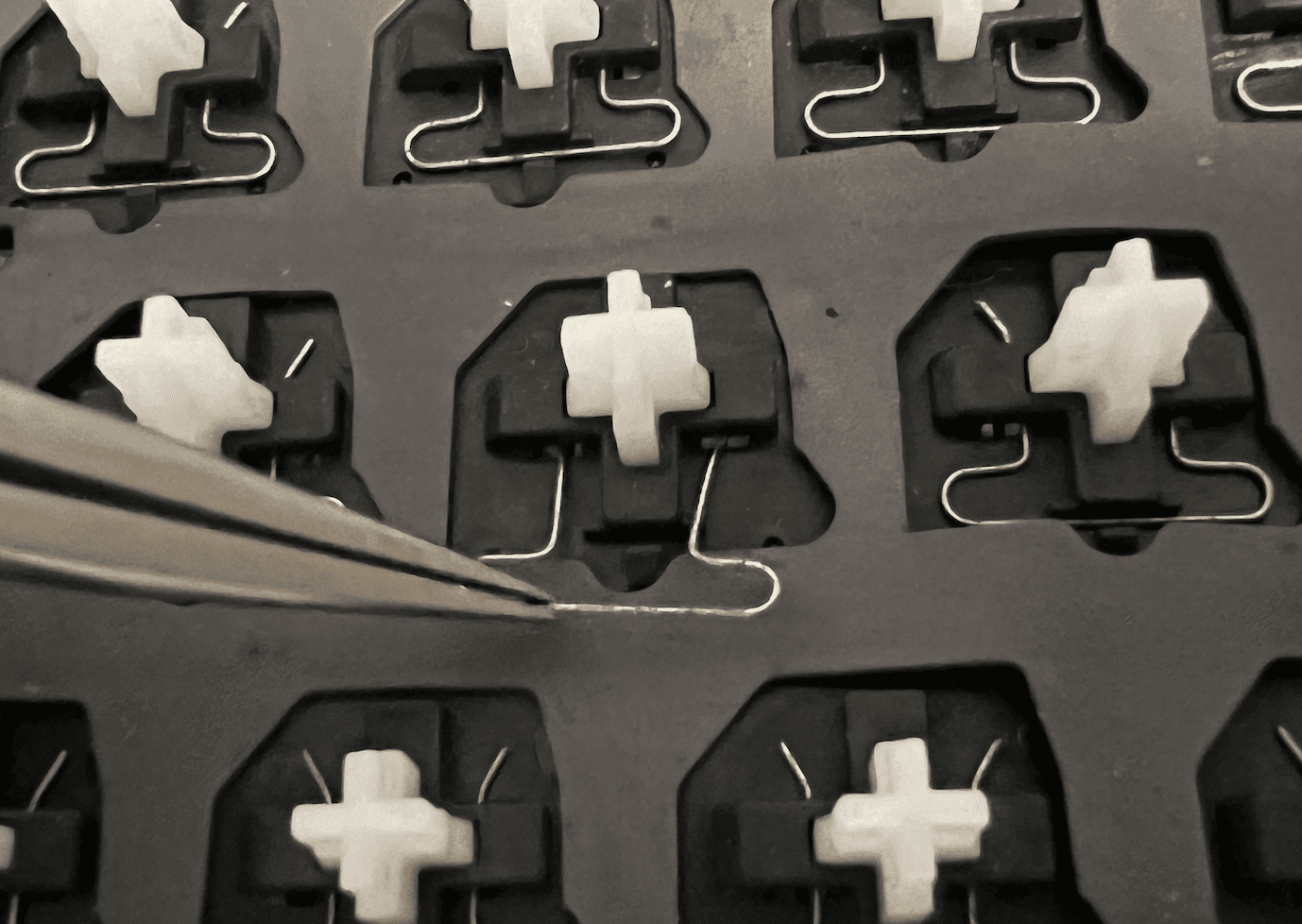

After removing the keycap, pull out the metal clip, like this:

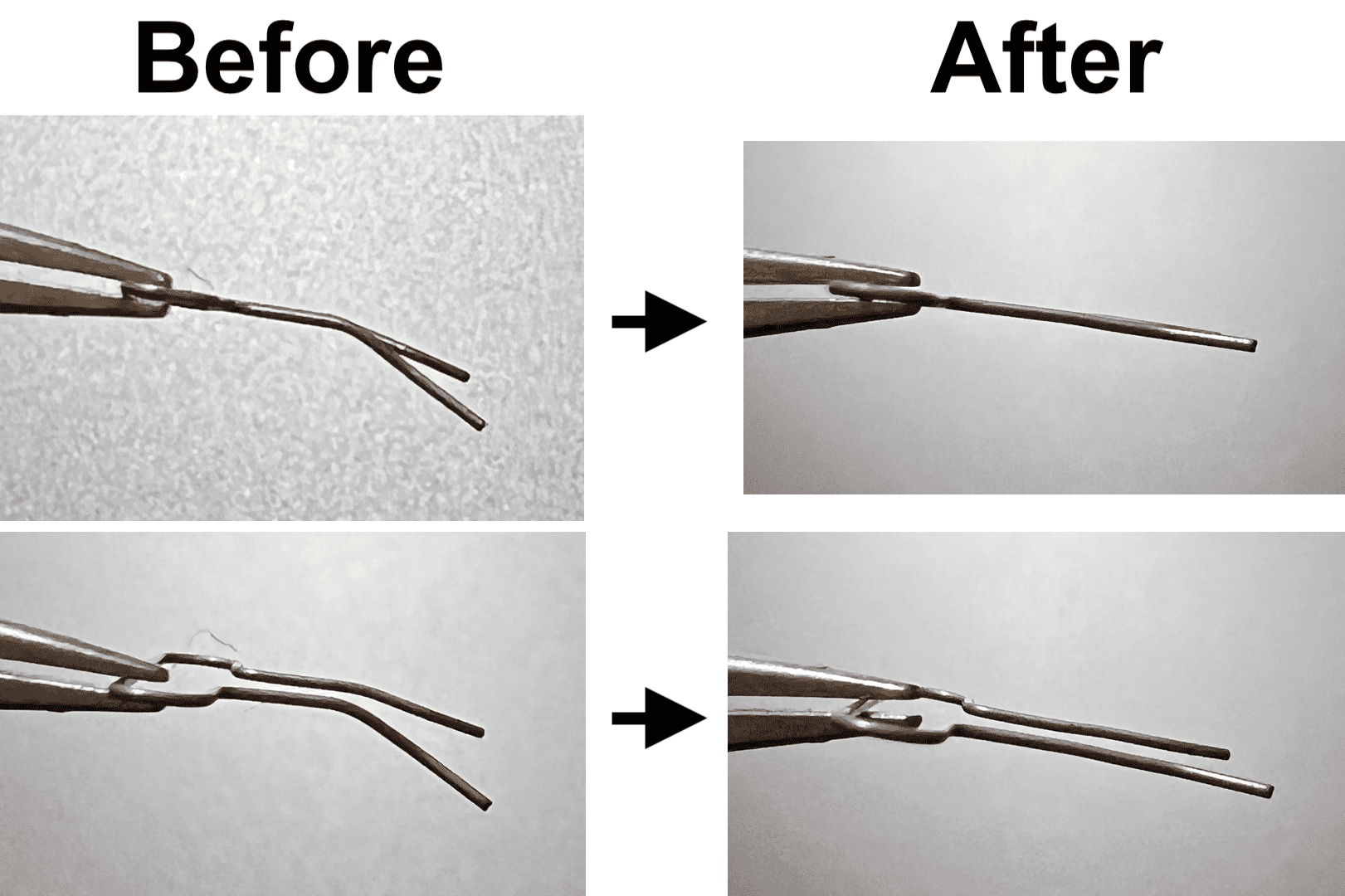

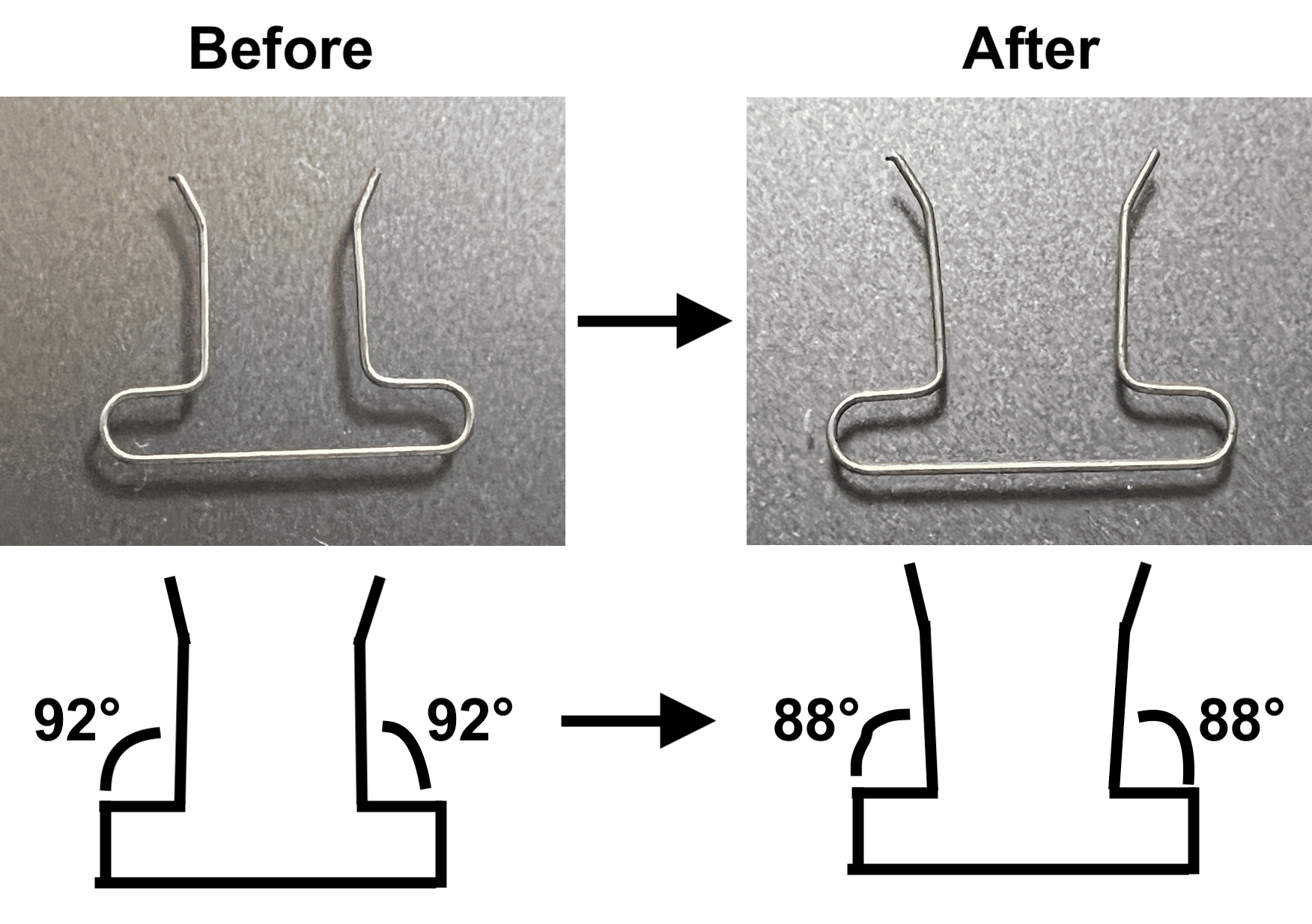

If the key was really hard to press and force was used, the metal clip was probably bend. The first steps is to unbend the clip if it's bend. If your clip has any bending as shown below, use tweezers to straighten them up. Here's an example of before/after:

The above fix alone will not fix the stiffness, the above bending is caused when the pin is already stiff.

To fix the stiffness, we need to use tweezers to adjust the angles of a bends in the clip. The adjustment is very subtlety outwards, as shown in below illustration.

If you don't spread them out enough, keys will be stiff to press. If you spread the clip outwards too much, you won't get any resistance whatsoever on the press. Ideally, key should be very easy to press with not lockups, but during the keypress you should see the metal clip vibrate. If the clip is not vibrating on the press, you've spread it too wide.

I recommend you do this for every single one of your keys. I also suggest that after doing this, let the keyboard sit for a day or two, and then retest. The wire may sightly bend back on its own to its original shape due to an alloy memory property, so additional adjustments may be needed the following day.

Once they switches are pressing fine, we can next lubricate them. I used Super Lube synthetic oil, which was recommended by JWD to use for floppy drives, it's perform for this application. Note this is optional as the improvement from the lube is very subtle.

The key here is to use it very sparingly. You don't ant to use too much causing it to leak inside and preventing contact when pressing they key. Also please don't use deoxit here.

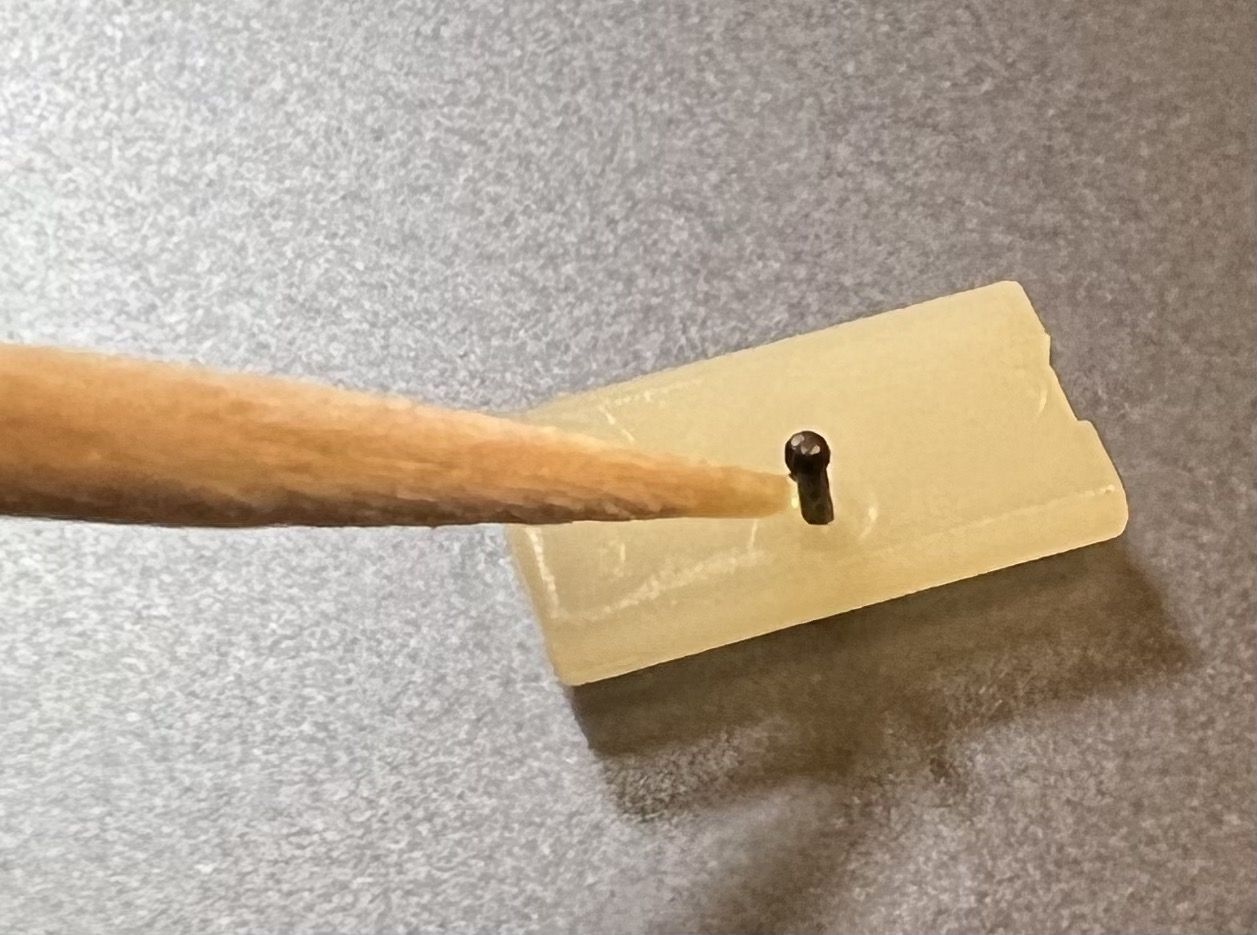

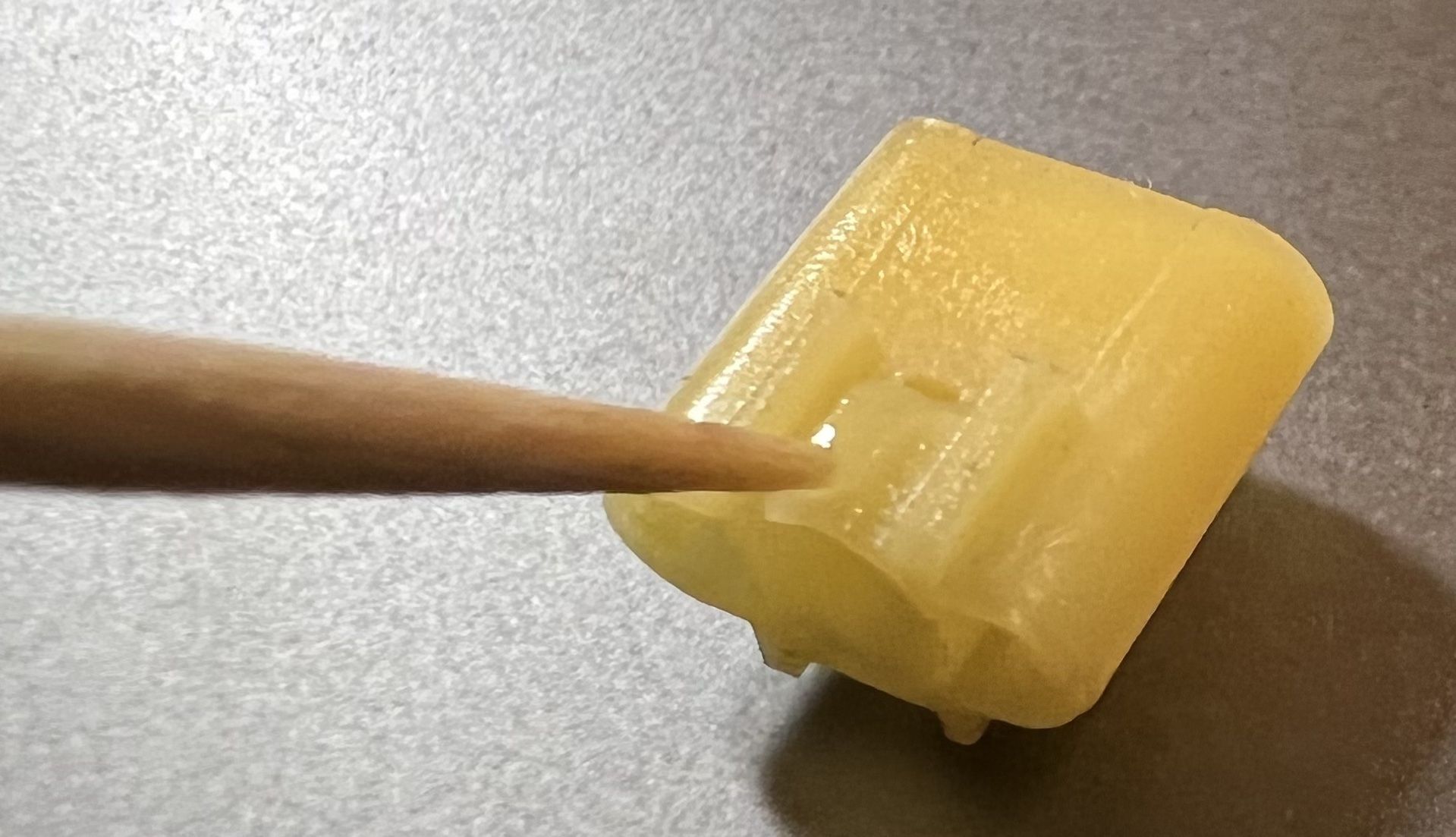

Using a toothpick, put a small drop of the synthetic oil on both sides of the switch indicated in the image below. This is the area that touches the metal clip as you press and release the key. One tiny drop is enough.

Here's a short video where I first show several keys I already fixed, followed by keys which have not yet been fixed:

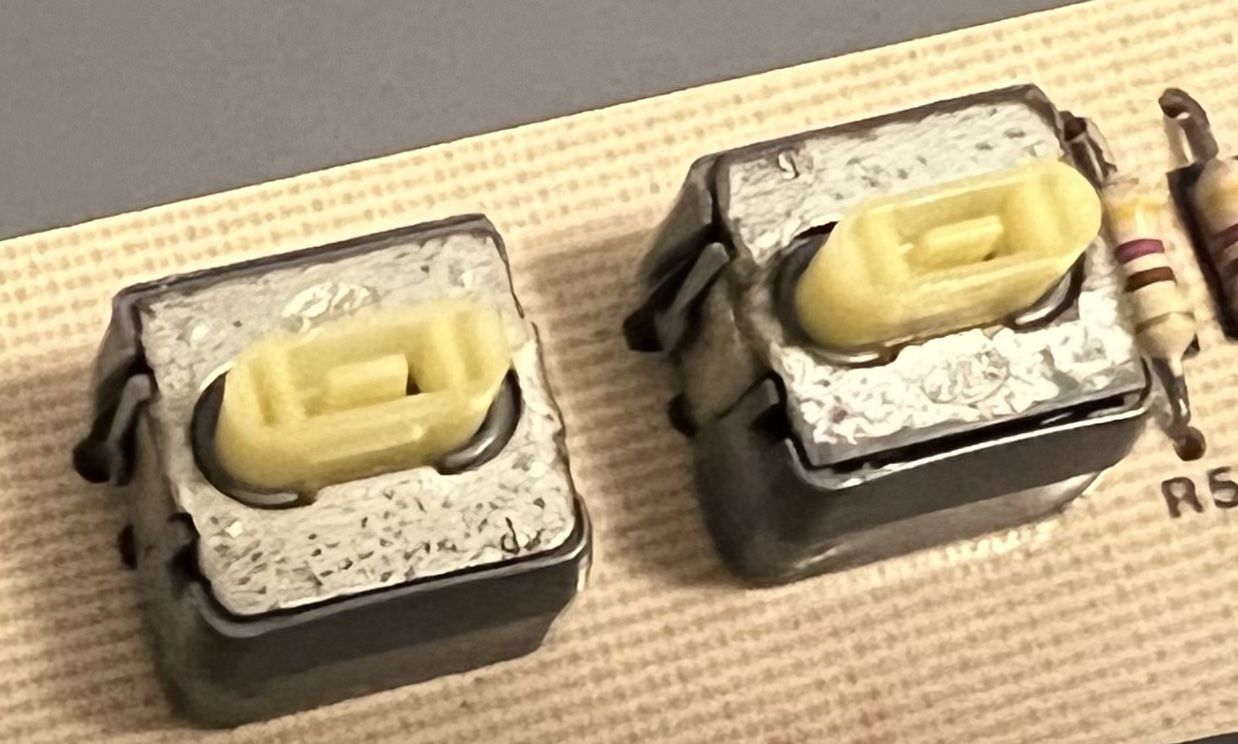

Next up are the keys with a latch, this keyboard has 3 of them. Unfortunately to repair these you will need to desolder 4 pins under each of these keys. Root cause of the issue is dirt as we'll soon discuss.

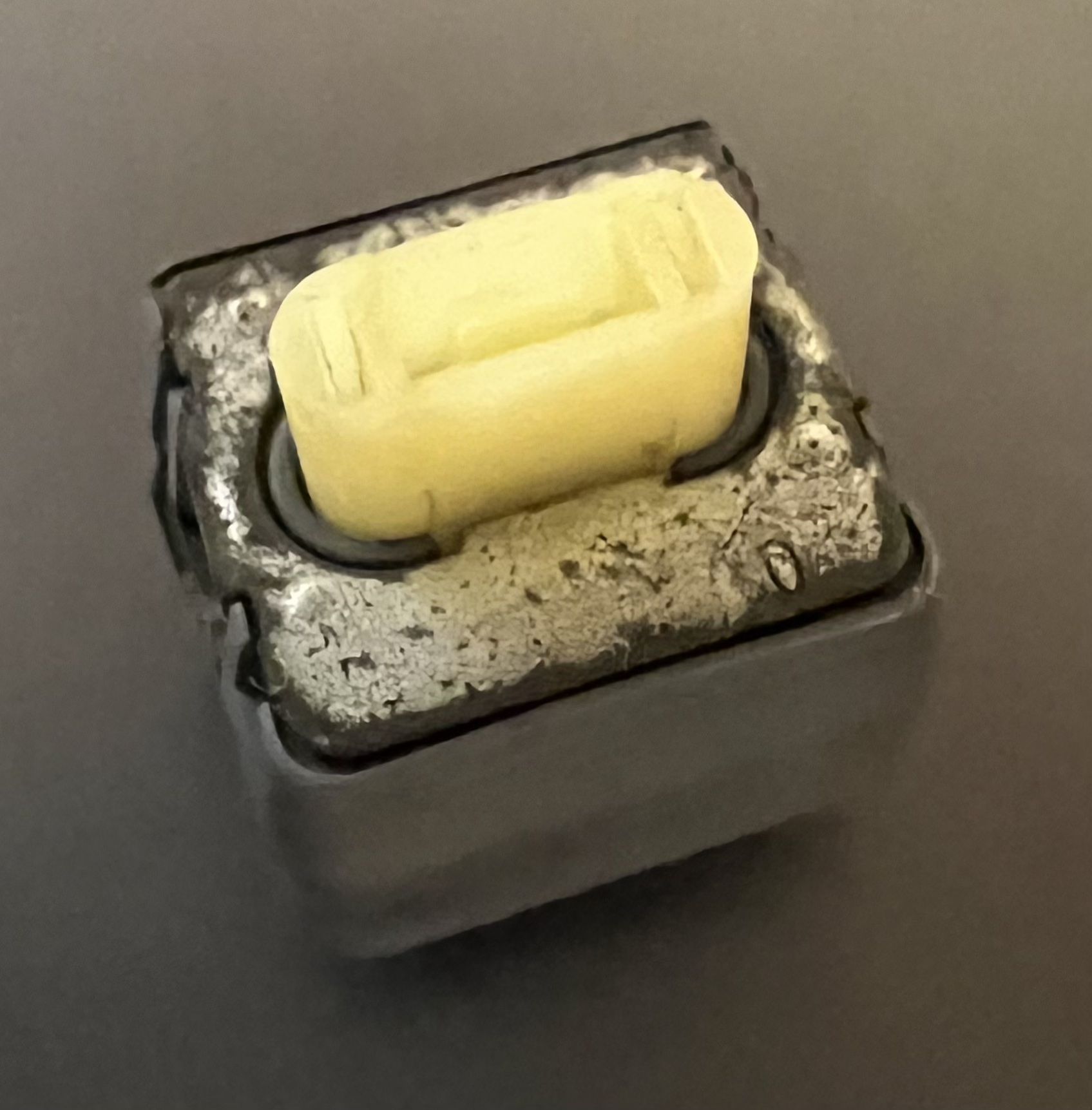

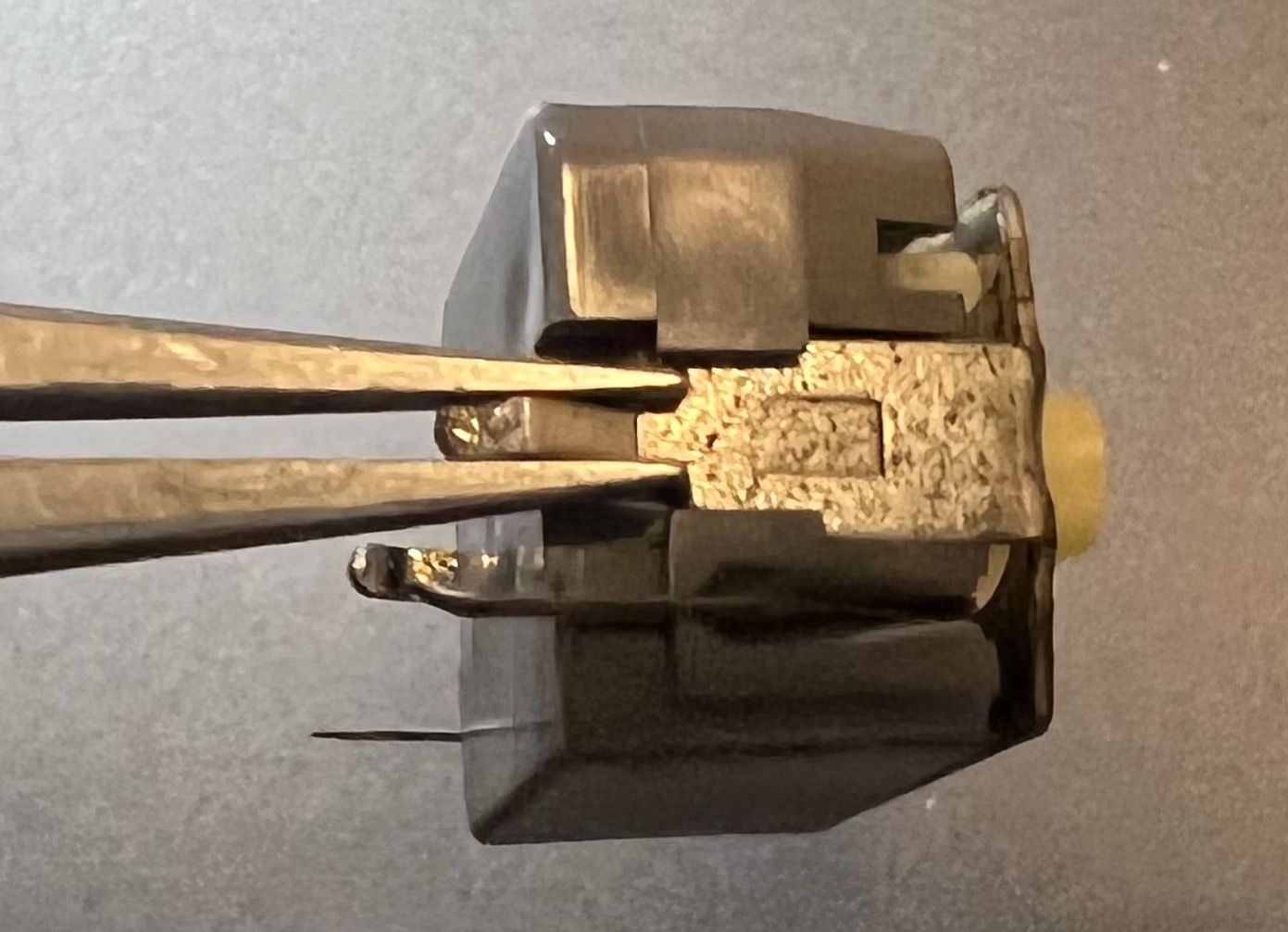

We need to get inside the switch. Remove the metal cover of the switch by grabbing it on the side using tweezers as indicated in the image below, and forcefully pushing up until it slides out. Below image shows how you can can slide it out if you grab it in this position.

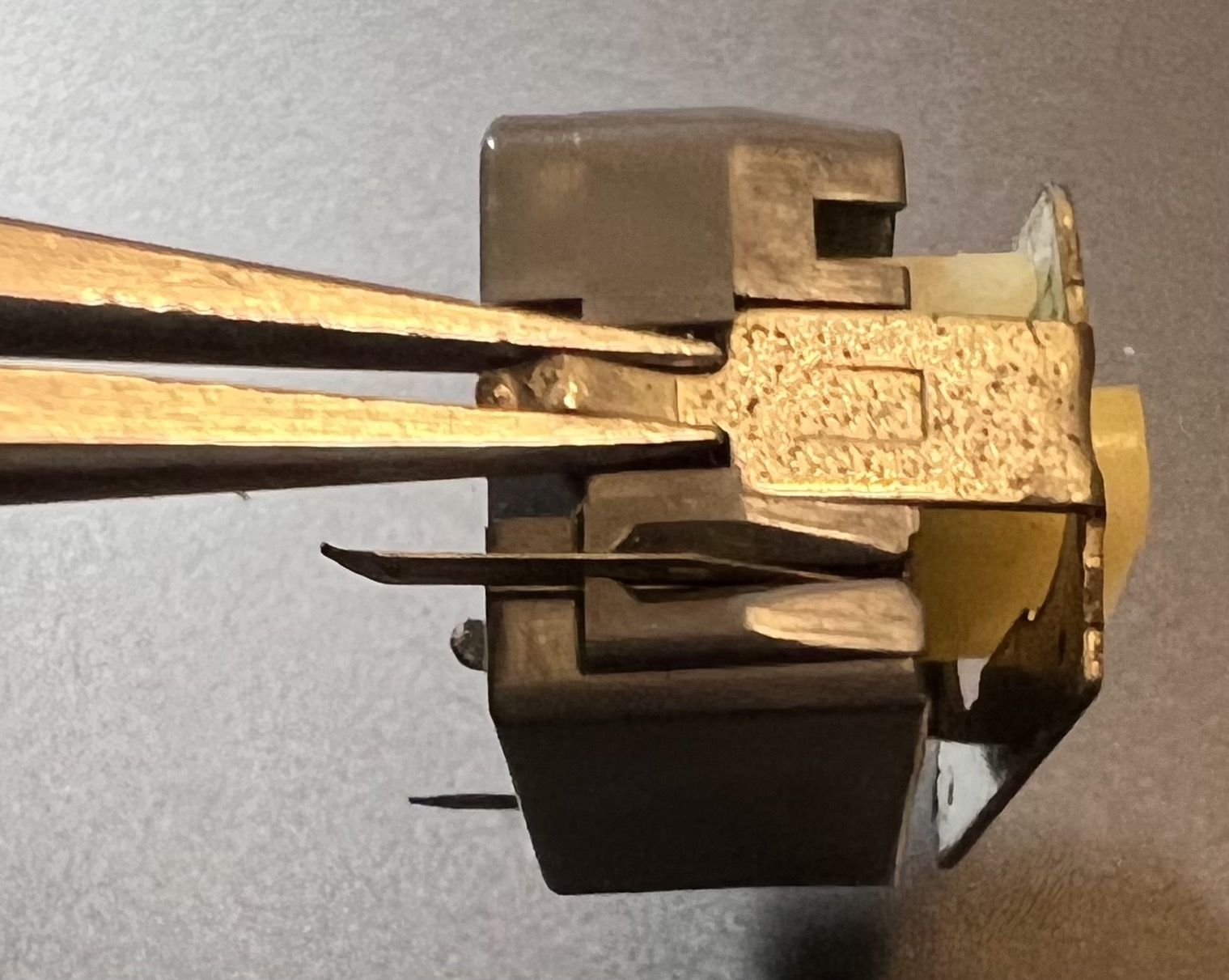

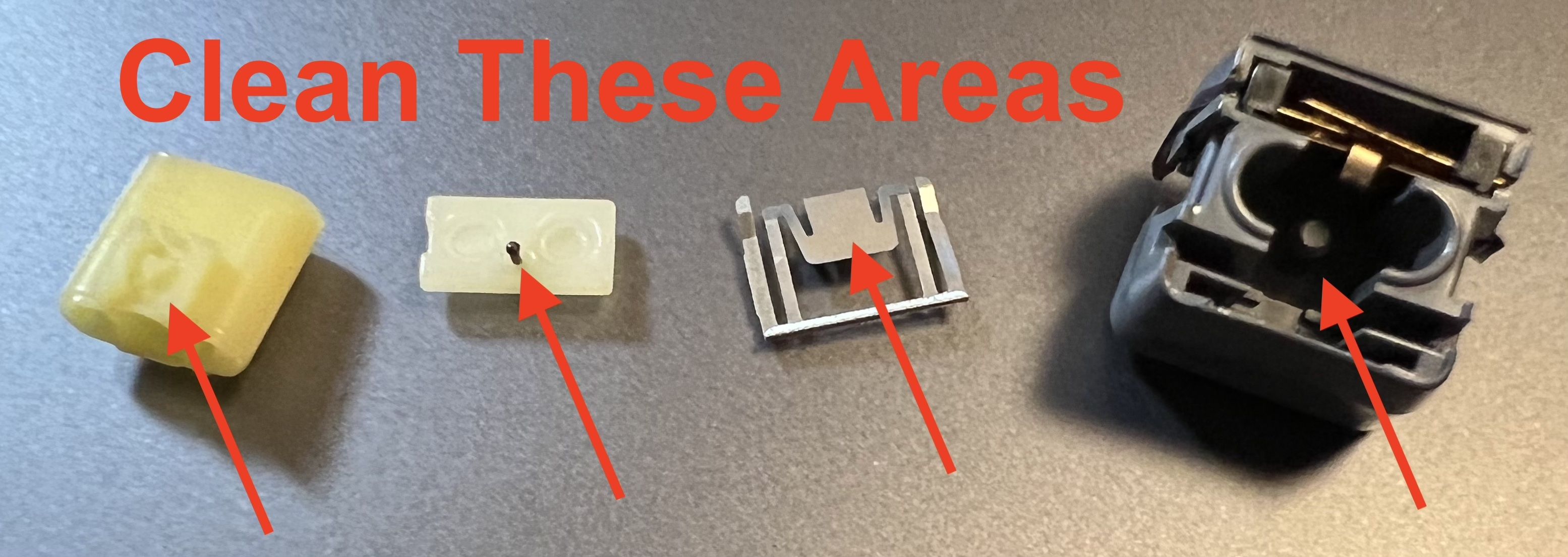

Take apart the key switch and place the parts as shown in the image below. Clean the areas indicated by the red arrows. Cleaning this will fix the latch issue. The main culprit is the very tiny nail going thought the piece of plastic, it's unable to slide smoothly though the plastic due to dirt preventing the locking and unlocking.

Lastly go back and add a very small amount of synthetic oil again to make the key presses even smoother. Once again, use a toothpick and place a very tiny dot on the two pieces of plastic indicated in the image below. Place the lube on both sides of both pieces of plastic.

When putting the switch back together, be careful not to insert the plastic piece with the tiny nail going thought backwards; the nail head should be touching the aluminum piece. I found that no bending of the aluminum piece inside the switch is needed for these keys. Bending it to make it more springy actually seemed to caused issues with the latch.

Here's a video of two keys side by side, with one which was just fixed.

Lastly, there is a removable black rubber spill protector (the one that is not stapled in) between the switches and keycaps, which on some keyboards disintegrates. Even if yours is still in good condition, take it out and trash it. It heavily dampens the key presses giving the keyboard a mushy feeling, removing it gives the keys a more satisfying press.

First, this fix only applies to the following keys. The keyboard PCB is by Photocircuits Atlanta with part 820 0108 03 and copyright date ©1983 printed on the back.

Fortunately, you don't need to desolder the key to fix the stiffness issue of the main keys. The issue is caused by a bend metal clip, which is easily accessible.

After removing the keycap, pull out the metal clip, like this:

If the key was really hard to press and force was used, the metal clip was probably bend. The first steps is to unbend the clip if it's bend. If your clip has any bending as shown below, use tweezers to straighten them up. Here's an example of before/after:

The above fix alone will not fix the stiffness, the above bending is caused when the pin is already stiff.

To fix the stiffness, we need to use tweezers to adjust the angles of a bends in the clip. The adjustment is very subtlety outwards, as shown in below illustration.

If you don't spread them out enough, keys will be stiff to press. If you spread the clip outwards too much, you won't get any resistance whatsoever on the press. Ideally, key should be very easy to press with not lockups, but during the keypress you should see the metal clip vibrate. If the clip is not vibrating on the press, you've spread it too wide.

I recommend you do this for every single one of your keys. I also suggest that after doing this, let the keyboard sit for a day or two, and then retest. The wire may sightly bend back on its own to its original shape due to an alloy memory property, so additional adjustments may be needed the following day.

Once they switches are pressing fine, we can next lubricate them. I used Super Lube synthetic oil, which was recommended by JWD to use for floppy drives, it's perform for this application. Note this is optional as the improvement from the lube is very subtle.

The key here is to use it very sparingly. You don't ant to use too much causing it to leak inside and preventing contact when pressing they key. Also please don't use deoxit here.

Using a toothpick, put a small drop of the synthetic oil on both sides of the switch indicated in the image below. This is the area that touches the metal clip as you press and release the key. One tiny drop is enough.

Here's a short video where I first show several keys I already fixed, followed by keys which have not yet been fixed:

Next up are the keys with a latch, this keyboard has 3 of them. Unfortunately to repair these you will need to desolder 4 pins under each of these keys. Root cause of the issue is dirt as we'll soon discuss.

We need to get inside the switch. Remove the metal cover of the switch by grabbing it on the side using tweezers as indicated in the image below, and forcefully pushing up until it slides out. Below image shows how you can can slide it out if you grab it in this position.

Take apart the key switch and place the parts as shown in the image below. Clean the areas indicated by the red arrows. Cleaning this will fix the latch issue. The main culprit is the very tiny nail going thought the piece of plastic, it's unable to slide smoothly though the plastic due to dirt preventing the locking and unlocking.

Lastly go back and add a very small amount of synthetic oil again to make the key presses even smoother. Once again, use a toothpick and place a very tiny dot on the two pieces of plastic indicated in the image below. Place the lube on both sides of both pieces of plastic.

When putting the switch back together, be careful not to insert the plastic piece with the tiny nail going thought backwards; the nail head should be touching the aluminum piece. I found that no bending of the aluminum piece inside the switch is needed for these keys. Bending it to make it more springy actually seemed to caused issues with the latch.

Here's a video of two keys side by side, with one which was just fixed.

Lastly, there is a removable black rubber spill protector (the one that is not stapled in) between the switches and keycaps, which on some keyboards disintegrates. Even if yours is still in good condition, take it out and trash it. It heavily dampens the key presses giving the keyboard a mushy feeling, removing it gives the keys a more satisfying press.

Last edited: