After successfully recapping and replacing the Hybrid (thanks again @Androda ), I needed to correct one faulty matrix line of the display.

I replaced the flat ribbon connector as it was torn at different places.

Unfortunately, same issue.

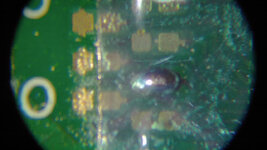

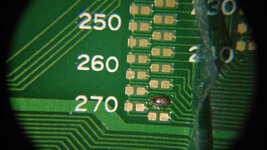

Checking the back of the display more carefully, I realized that there was a kind of corrosion under the protective adhesive.

I had this type of corrosion once in a LCII PSU, probably due to a bad board cleaning at manufacturing.

Sorry for the bad quality, my camera was out focus...

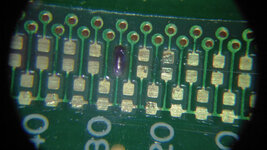

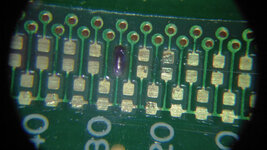

To my surprise, after replacing the protective adhesive, pads were perfect!

Back to square one.

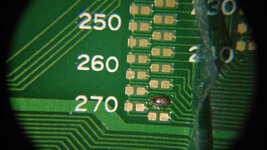

Checking the whole board, I realized that other areas have the same aspects.

I plan to remove the protective adhesive from the additional places, but is it normal to have these solder connecting pads?

I have that at 4 different places on the board.

Thanks for your advices.

I replaced the flat ribbon connector as it was torn at different places.

Unfortunately, same issue.

Checking the back of the display more carefully, I realized that there was a kind of corrosion under the protective adhesive.

I had this type of corrosion once in a LCII PSU, probably due to a bad board cleaning at manufacturing.

Sorry for the bad quality, my camera was out focus...

To my surprise, after replacing the protective adhesive, pads were perfect!

Back to square one.

Checking the whole board, I realized that other areas have the same aspects.

I plan to remove the protective adhesive from the additional places, but is it normal to have these solder connecting pads?

I have that at 4 different places on the board.

Thanks for your advices.

Last edited: