I recently got a Metcal SP-440 Self-Contained Desolder System. Since there's so little info about this device online, I figured it'd be helpful to share my experience finding one, getting it working and some DIY recipes for hard-to-find consumables.

I've been very happy with other Metcal gear I've picked up used over the past year, so have been curious to try their desoldering tools. They make a hand piece compatible with the MX-500 station I'm using, but it requires shop air. Their current generation self-contained desolder system is the MFR-1350. It's ~$800 new and rarely shows up used for cheap. The SP-440 was discontinued around 2004 from what I can tell. The main differences seem to be that the MFR-1350 has a slightly stronger vacuum (21"Hg vs 18"Hg), a detachable pistol grip and a second hand piece port. One forum post online mentioned the build quality of the MFR-1350 seemed slightly worse than the SP-440.

The unit I received did not have an installed chamber liner or fume filter. There was also an inline filter that probably needed to be changed. Further, it had a vacuum leak somewhere. The pump would cycle continuously even when the vacuum button was not pressed. The manual indicated this could be due to a bad seal in the coil assembly.

Getting official supplies was expensive, but after seeing them in person I realized they can easily be made DIY.

Trying to desolder something like a RAM slot quickly is still a chore at first pass. Not all joints wet immediately and need additional fresh solder to get them moving. Though I still need to experiment with the various cartridge sizes.

I'll update this post once I've lived with it for a while and try to do some tests directly comparing its performance to the FR-301.

Why the SP-440?

Like many of you, I've been using a Hakko FR-301 desoldering pump for several years now. It's a nice tool to have, but not without its imperfections. It gets clogged a lot, doesn't have quick change nozzles and struggles on ground pins.I've been very happy with other Metcal gear I've picked up used over the past year, so have been curious to try their desoldering tools. They make a hand piece compatible with the MX-500 station I'm using, but it requires shop air. Their current generation self-contained desolder system is the MFR-1350. It's ~$800 new and rarely shows up used for cheap. The SP-440 was discontinued around 2004 from what I can tell. The main differences seem to be that the MFR-1350 has a slightly stronger vacuum (21"Hg vs 18"Hg), a detachable pistol grip and a second hand piece port. One forum post online mentioned the build quality of the MFR-1350 seemed slightly worse than the SP-440.

Finding one to buy

I have noticed a lot of the older SP-440 systems on eBay with very good prices, but almost all of them are missing the hand piece, stand, cartridges and other accessories. Fortunately I found one on FaceBook Marketplace recently with all of the bits and pieces for about $80.The unit I received did not have an installed chamber liner or fume filter. There was also an inline filter that probably needed to be changed. Further, it had a vacuum leak somewhere. The pump would cycle continuously even when the vacuum button was not pressed. The manual indicated this could be due to a bad seal in the coil assembly.

Parts & Supplies

Parts and supplies for the SP-440 are very hard to find since it's been discontinued so long. The only place I could find liners, filters and seals was on KAV Systems' sketchily-named website www.used-electronic-equipment-buy-and-sell.com. To my surprise, I actually received the items ordered rather quickly, considering they came from Italy in the summer. Unfortunately they did not stock the in-line filters, but after consulting with Metcal, found that a generic filter can be used.Getting official supplies was expensive, but after seeing them in person I realized they can easily be made DIY.

Chamber Liner

The chamber liner is just a folded piece of filter paper. It looks like a picket fence that you then roll into shape. When I run out of the real deal, my plan is to use the attached template to cut some coffee filters into the same shape. The official part number is DP-CF and includes 24 chamber liners and 12 fume filters.Fume Filters

The fume filters are very similar to the Hakko FR-301 filters. It's a felt-like material that's 14.5mm in diameter and 7mm H — slightly larger than the Hakko filters. The Hakko filters or other similar type of filter material could be cut down to size with a hobby knife or ideally a punch tool.In-line filters

I couldn't find a source to buy the Metcal branded in-line filter. Metcal sales was unable to help, other than saying a generic filter would work fine. I found some generic filters on Amazon by searching for "Barbed Air Line Filter" and "in-line air filter". The barbs should be a little over 1/4" and the filter itself should be about 50mm in diameter.Coil Assembly Seal

This rubber seal has somewhat complex geometry that would be difficult to replace in a DIY manner. It may be possible to 3D print a mold and cast with something like silicone, but it may be hard to achieve the precision needed. The official part number is DP-SL3.Cartridge Holder

I was lucky to receive a lot of cartridges with my unit, but they were just in a plastic bag. I designed and 3D printed a stand to hold them which is working well. The STL file is attached to this post.Vacuum Leak Fix

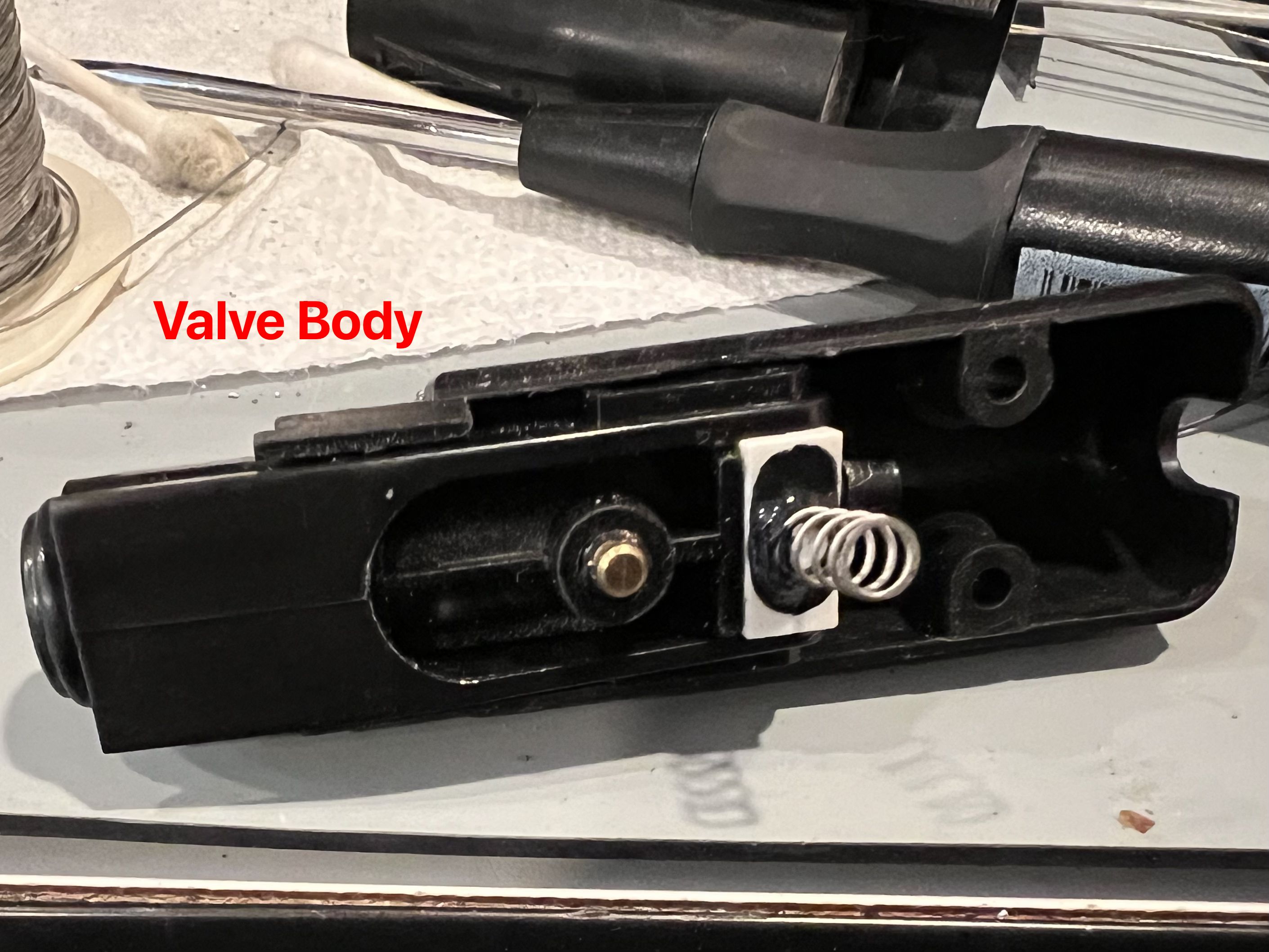

I assumed the vacuum leak was due to the missing liner, filter and possibly bad seal. After replacing all of those, the issue persisted. I noticed that if I pinched the air hose just before the hand piece, the vacuum pump would stop. So the leak was definitely in the hand piece. I removed the valve body from the hand piece and took off the vacuum hose from the valve body. I then blew into the valve while holding it open. Something let free (solder ball?) and the valve started working properly. After reassembling everything the pump stopped cycling.So, is it any good?

The short answer is that I need to spend more time with it. Build quality and ergonomics are very nice. The unit comes to temperature in just a few seconds and runs very quiet. Changing cartridges is as easy as pulling one out with a silicone pad and smushing a new one into place. There is a set of cartridge files included which is quite nice for keeping the cartridges clear of clogs.Trying to desolder something like a RAM slot quickly is still a chore at first pass. Not all joints wet immediately and need additional fresh solder to get them moving. Though I still need to experiment with the various cartridge sizes.

I'll update this post once I've lived with it for a while and try to do some tests directly comparing its performance to the FR-301.