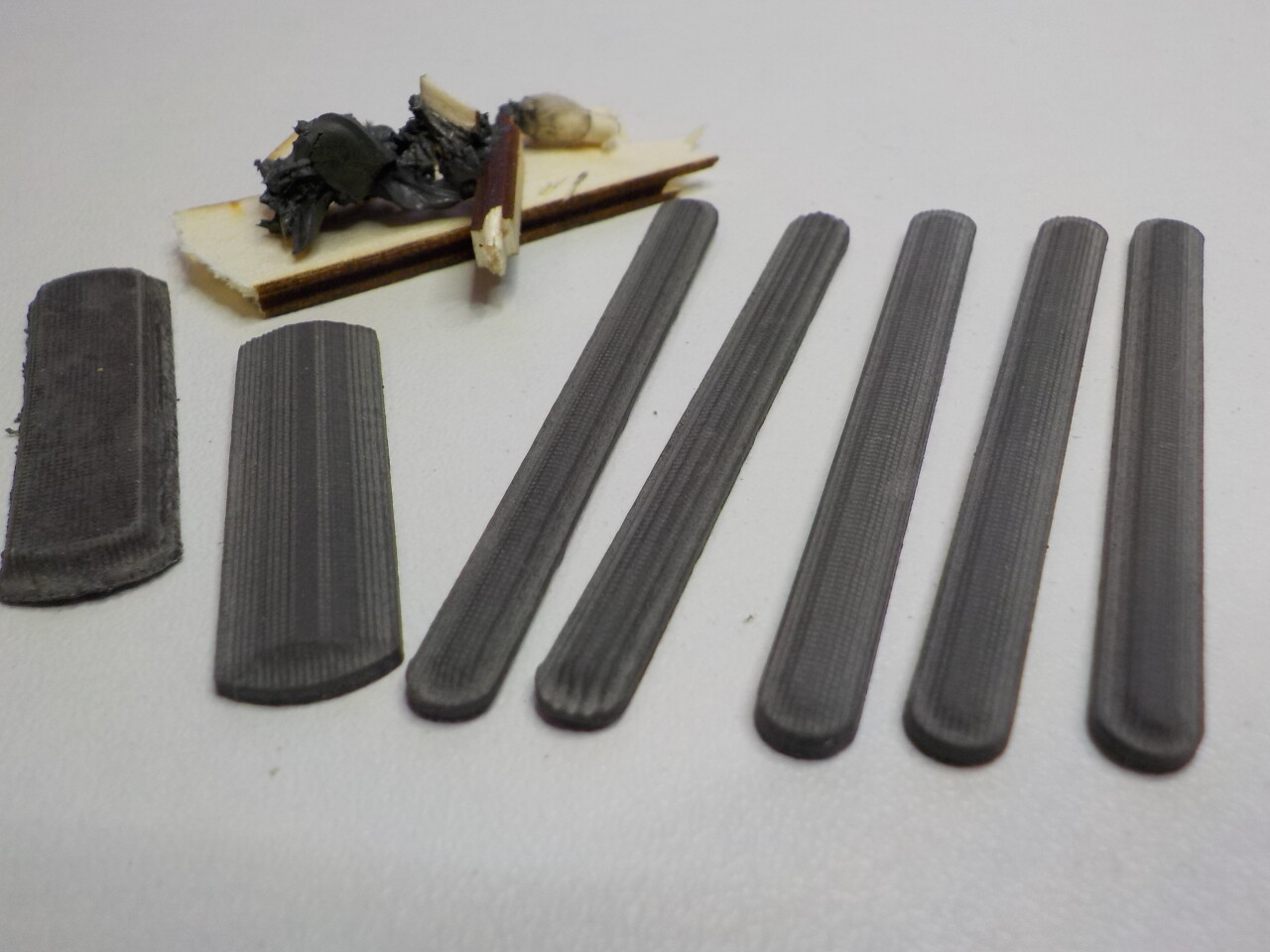

While some people managed to recreate rubber pads with 3D-printed TPU, and it can look quite okay, I thought it could look better, and I wanted to explore other methods. I've had the idea for some time, for another machine, but I had this Color StyleWriter 2200 around with feet turning into goo even faster…

At the fablab we have a large laser cutter, and I already ordered a rubber sheet with double-sided tape, the kind used to make stamps. So I first made a model in OpenSCAD, which could still be used for 3D printing if needed, but for 2D stuff OpenSCAD can only export outlines as SVG, it can't generate gradients for depth… So I redesigned it in Inkscape… but because out machine needs Corel Draw to run (vendor said it could be made to work with Inkscape but can be unstable…), and Corel Draw didn't like importing gradients from Inkscape, I first made a simple cut version:

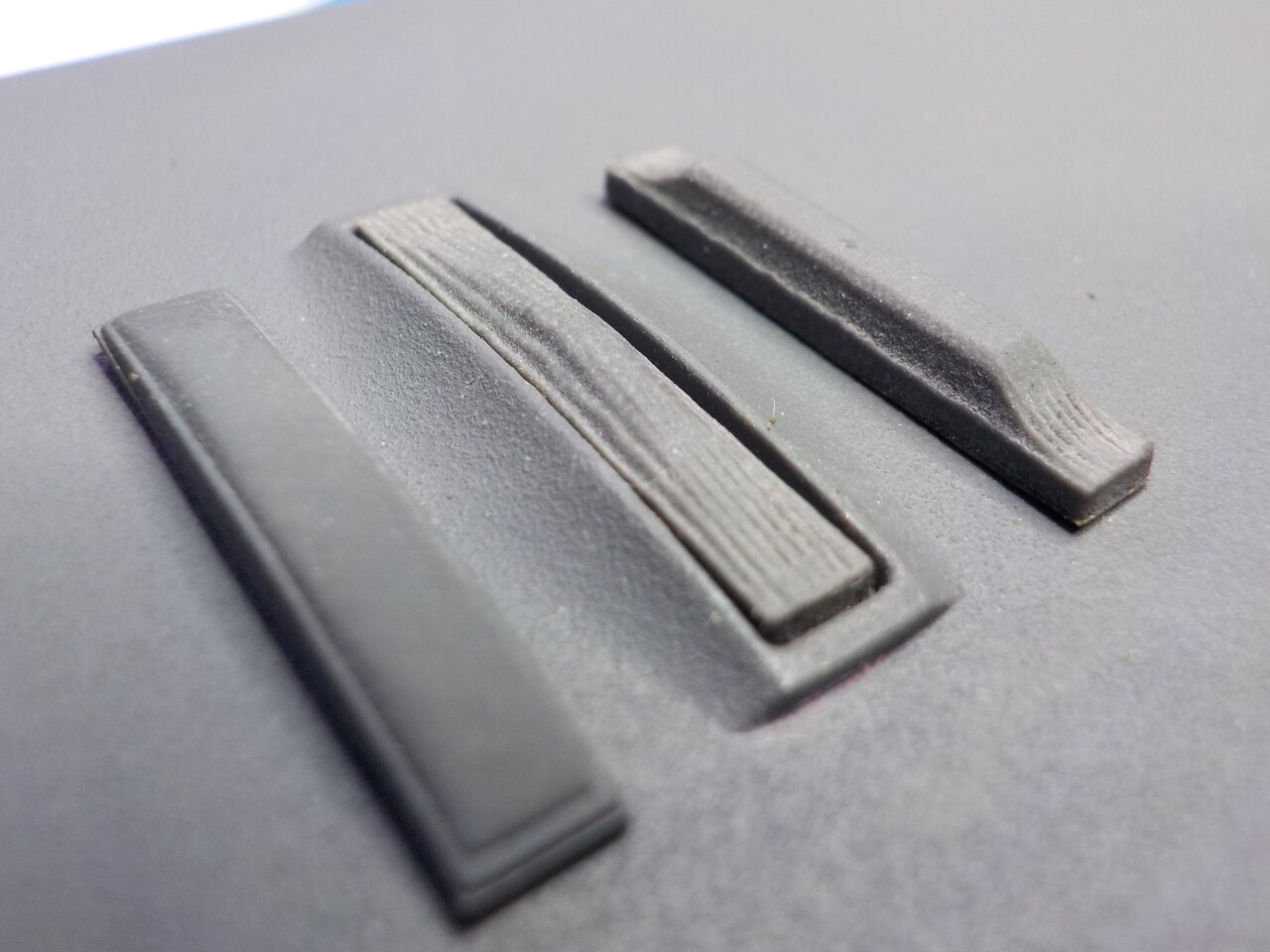

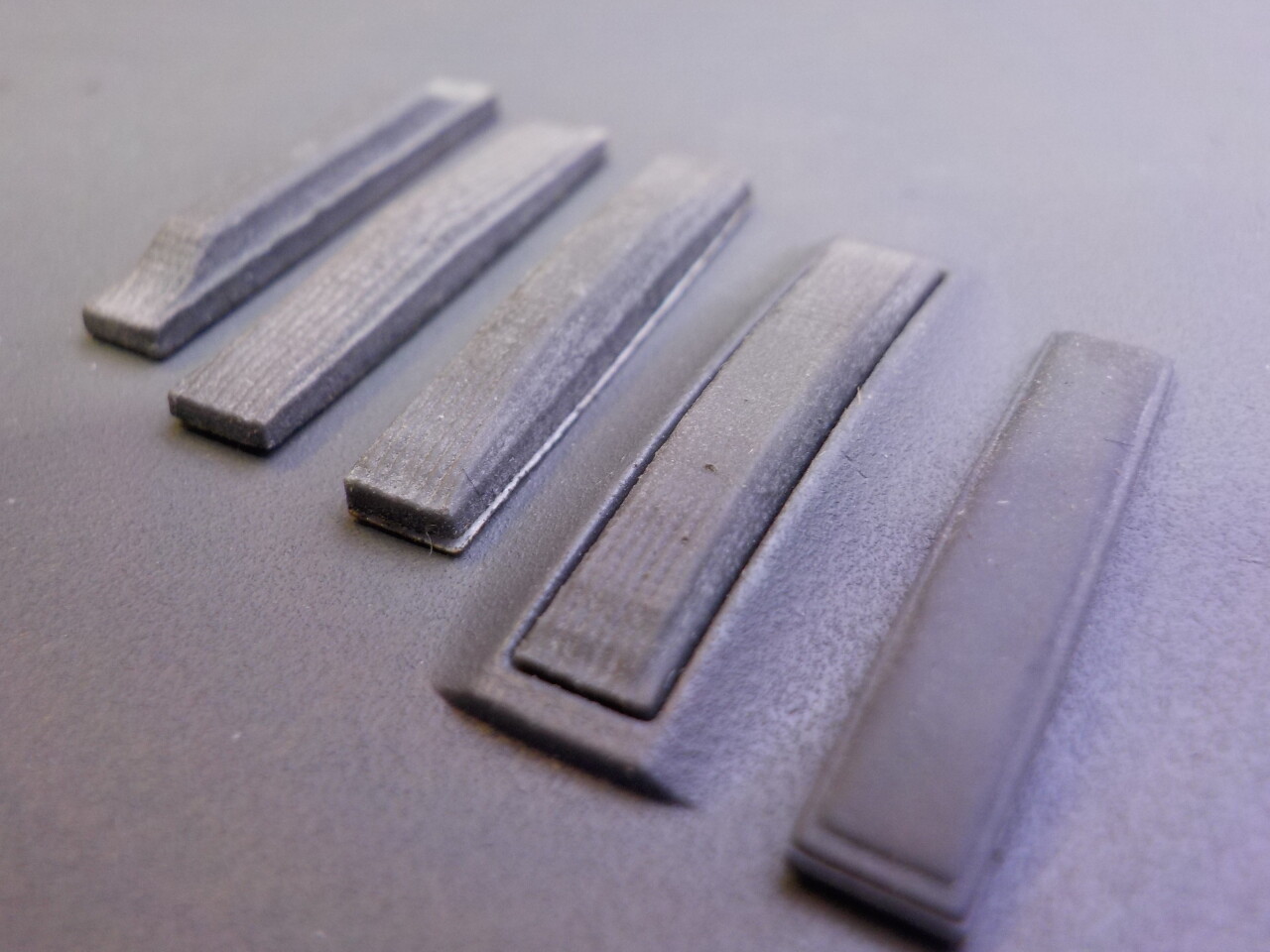

Which I had to finish cutting with scissors as the default settings was too fast to cut through, but it didn't look too bad. Except it's too thick and I feared it could get knocked off. So after some testing with gradients in Corel I managed to get a decent engraved version:

The grid shape is due to the rasterization of the gradient, maybe it can be made softer, but the result is not too bad. However if I want to make some to sell them cheap enough I'll probably need to do the whole 200 pairs in a sheet to spread the raster time across it.

At the fablab we have a large laser cutter, and I already ordered a rubber sheet with double-sided tape, the kind used to make stamps. So I first made a model in OpenSCAD, which could still be used for 3D printing if needed, but for 2D stuff OpenSCAD can only export outlines as SVG, it can't generate gradients for depth… So I redesigned it in Inkscape… but because out machine needs Corel Draw to run (vendor said it could be made to work with Inkscape but can be unstable…), and Corel Draw didn't like importing gradients from Inkscape, I first made a simple cut version:

Which I had to finish cutting with scissors as the default settings was too fast to cut through, but it didn't look too bad. Except it's too thick and I feared it could get knocked off. So after some testing with gradients in Corel I managed to get a decent engraved version:

The grid shape is due to the rasterization of the gradient, maybe it can be made softer, but the result is not too bad. However if I want to make some to sell them cheap enough I'll probably need to do the whole 200 pairs in a sheet to spread the raster time across it.