Do you happen to have photos on the process, or the battery setup?

No, but I do happen to have a couple dead batteries open on my bench and took some pics (attached):

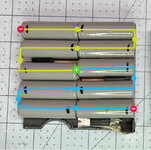

- First image shows the open seam. Note the part of the case around the terminals is not welded, it just separates. You only need to work around the seam on the top side. I just slowly, lightly cut with a scalpel - razor or x-acto will also work, a thin very sharp blade - all around in the groove of the seam. Takes maybe 10 or 15 minutes, tops. I do it on the couch while watching tv.

- The second image shows the cover off and the arrangement of batteries inside --- the black lines on the batteries note the negative ends. The black rectangles are temperature sensors, which are - in this case - connected between the last two batteries in each series.

- The third image illustrates how the batteries are connected.

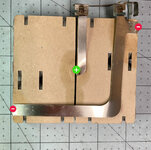

- The fourth image shows the reverse of the assembly, showing how the series connect to the terminal strips.

The only parts of the assembles I reuse are the sensors and the terminal strips. Sometimes the insulating paper can be salvaged, but really depends on the glue or the state of corrosion. If the paper can't be salvaged, you can just recreate it with card stock or something similar.

Note that not all of the Apple branded PB batteries are the same inside, they can differ slightly. But the general idea is the same.

I don't have any photos of the tabbing / repacking process I use, and I don't have any flat-top batteries handy to replicate it, but for each battery connection it's the same steps.

However, I really want to advise caution... I actually recommend using a spot welder and nickel strips for this, but I'm reckless so here's a video that goes through the same steps I follow:

Note that it's

very important to use a HOT iron (800+) and BIG tip to minimize soldering time... you can damage the battery if it gets too hot, or even result in thermal runaway in extreme cases. The sanding and fluxing also keeps things quick.

Also, don't glue the batteries together as demonstrated in the above video, since the arrangement is obviously different in the PB case.

There are also flat-top NiMH batteries that have tabs pre-installed if you're concerned about soldering directly on the terminals or don't have an iron that can get hot enough. I've used them once, and found it kinda fussy, but it worked.