I took your parts and modified them a bit for resin printing. I twisted the hex pattern in the knob to allow the hex key to fit and bend into the notch. I also added a hex inset in the front bezel to accept a m4 hex nut glued in (instead of melted). I also changed the two screw towers (not sure the official name) that were meant for heat inserts and made them solid cylinders with a 2.7mm hole that I hope will accept a M3 screw direct screwed into the resin. I also enlarged the holes on the back plate to accept the new M3 screws in the bottom (I believe you had M2 screws in the bottom spots). Once they arrive and I confirm they work, properly, I will share the STLs.

Custom USB-C powered 8"display for the Apple IIc with STL files and build plan

- Thread starter ArjenCNX

- Start date

-

Please can you read through and vote on the following proposition for changes to the board structure by clicking here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cool mods, for the knob it makes sense to rotate the hex profile, it will make things fit better, for the bezel part, adding the M4 nut is a concern, as the screws on the sides will pull on it all the time, it is quite likely to get loose over time. with inserts this risk is substantially lower. maybe a better solution for a nice stiff hinge can be made, that requires less force on the insert/nut. I'll just throw it in the Hive mind, any ideas are welcome, if you got some, please comment below.I took your parts and modified them a bit for resin printing. I twisted the hex pattern in the knob to allow the hex key to fit and bend into the notch. I also added a hex inset in the front bezel to accept a m4 hex nut glued in (instead of melted). I also changed the two screw towers (not sure the official name) that were meant for heat inserts and made them solid cylinders with a 2.7mm hole that I hope will accept a M3 screw direct screwed into the resin. I also enlarged the holes on the back plate to accept the new M3 screws in the bottom (I believe you had M2 screws in the bottom spots). Once they arrive and I confirm they work, properly, I will share the STLs.

View attachment 24823

View attachment 24824

Yeah, I am hoping a liberal amount of superglue will hold as well as an insert. Alternatively, a longer screw with a nut that could be inserted into a notch in the hinge area so it is pulling against the printed part, as opposed to requiring glue to hold? I am impatient so I sent off the original to be printed, but may order this version as well, because I think long term it will be much less likely to fail.Cool mods, for the knob it makes sense to rotate the hex profile, it will make things fit better, for the bezel part, adding the M4 nut is a concern, as the screws on the sides will pull on it all the time, it is quite likely to get loose over time. with inserts this risk is substantially lower. maybe a better solution for a nice stiff hinge can be made, that requires less force on the insert/nut. I'll just throw it in the Hive mind, any ideas are welcome, if you got some, please comment below.

I will probably wait until I have parts for the iPad 10" version to order this one. Once I do, and if it works, I will post the STL files as a "resin optimized" version.

how about screw inserts, what they use when the wire-tap is damaged? they look like springs. if you can insert that, it will cover much more depth, and that should be stronger. I'm always concerned with the brittleness of the material, not much unlike the LC575 I'm fixing now.... Biscuit's.Yeah, I am hoping a liberal amount of superglue will hold as well as an insert. Alternatively, a longer screw with a nut that could be inserted into a notch in the hinge area so it is pulling against the printed part, as opposed to requiring glue to hold? I am impatient so I sent off the original to be printed, but may order this version as well, because I think long term it will be much less likely to fail.

View attachment 24922

I will probably wait until I have parts for the iPad 10" version to order this one. Once I do, and if it works, I will post the STL files as a "resin optimized" version.

Are you taking about something like helical inserts? https://a.co/d/7kPyx3Ohow about screw inserts, what they use when the wire-tap is damaged? they look like springs. if you can insert that, it will cover much more depth, and that should be stronger. I'm always concerned with the brittleness of the material, not much unlike the LC575 I'm fixing now.... Biscuit's.

If the resin material is brittle, would this helical coils not break the tiny threads it creates when it is inserted?

it feels like the pressure needed to keep this display upright shouldn’t be too much and so I feel like maybe the force on this bolt shouldn’t be super high. But we’ll see.

Maybe you are right, still, if we want to prevent stresses from building up, gluing is still best, this will need surface area to be stable over time. a melt-in insert is still best here in that case, glued in place with epoxy or maybe even yellow glue (shoe repair glue) as it never fully hardens

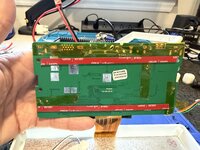

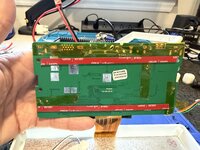

Just an update... I did get my CR10 working now, but I still need a little fine tuning before I run a bunch of Platinum PLA through it. This is the 9.7" iPad 1st Gen version of this build.

I made the screw holes very tiny as they have very tiny machine screws holding it into an iPad frame. I have some coarse "wood screws" from small electronic projects to install the screen.

The four side ones lined up nicely, but the two bottom ones, I cannot find the holes, so either they are off, the 3D print is off, or the holes were too small to be printed correctly. Disassembly required to investigate.

I made the screw holes very tiny as they have very tiny machine screws holding it into an iPad frame. I have some coarse "wood screws" from small electronic projects to install the screen.

The four side ones lined up nicely, but the two bottom ones, I cannot find the holes, so either they are off, the 3D print is off, or the holes were too small to be printed correctly. Disassembly required to investigate.

Got my replacement case parts optimized for resin. with the updated orientation for the hex key, It's the original front case with the glue / press in slot for the nut on the hinge, so we'll see how it holds up and I may reprint just the front if the superglued nut doesn't withstand the stress from the bolt. I may also see if I could put some epoxy around the rim to strengthen it.

But the case works really well. Using double sided tape to hold in the screen (vs the original LCD's bracket, the contents fit without knocking a hole in the back . Also, using direct screw posts for attaching the back plate worked great, and should support both resin and PLA / ABS prints. I don't have the paper washers of the correct length bolt, so I can't fully assemble, but it looks very nice in the resin!

. Also, using direct screw posts for attaching the back plate worked great, and should support both resin and PLA / ABS prints. I don't have the paper washers of the correct length bolt, so I can't fully assemble, but it looks very nice in the resin!

Also, @phunguss, I figured out my 3d printer issue and could try to do a test print of your iPad LCD version. I slow can help modify it for use with resin printing if you'd like, similar to what I did for @ArjenCNX 's model. Thanks again to both of you for doing the leg work on these. Really excited to have a fully assembled set of displays for my IIc and IIc Plus machines.

But the case works really well. Using double sided tape to hold in the screen (vs the original LCD's bracket, the contents fit without knocking a hole in the back

Also, @phunguss, I figured out my 3d printer issue and could try to do a test print of your iPad LCD version. I slow can help modify it for use with resin printing if you'd like, similar to what I did for @ArjenCNX 's model. Thanks again to both of you for doing the leg work on these. Really excited to have a fully assembled set of displays for my IIc and IIc Plus machines.

Last edited:

Very smooth, looks nicer than extrusion printing, make sure you add a washer (nylon/plastic) in between the hinge part of the bezel where it meets the base (where the long M4 screw meets the bezel) id love to know what the print costs in total, and how the materials hold up over time, i would avoid sunshine directly on the display.Got my replacement case parts optimized for resin. with the updated orientation for the hex key, It's the original front case with the glue / press in slot for the nut on the hinge, so we'll see how it holds up and I may reprint just the front if the superglued nut doesn't withstand the stress from the bolt. I may also see if I could put some epoxy around the rim to strengthen it.

But the case works really well. Using double sided tape to hold in the screen (vs the original LCD's bracket, the contents fit without knocking a hole in the back. Also, using direct screw posts for attaching the back plate worked great, and should support both resin and PLA / ABS prints. I don't have the paper washers of the correct length bolt, so I can't fully assemble, but it looks very nice in the resin!

View attachment 25191 View attachment 25192 View attachment 25193

View attachment 25194 View attachment 25195 View attachment 25196

Also, @phunguss, I figured out my 3d printer issue and could try to do a test print of your iPad LCD version. I slow can help modify it for use with resin printing if you'd like, similar to what I did for @ArjenCNX 's model. Thanks again to both of you for doing the leg work on these. Really excited to have a fully assembled set of displays for my IIc and IIc Plus machines.

I assume you're talking about the resin case being in sunlight? I've heard of yellowing of resin prints. I'm likely to try to paint it when I have it all set up and mostly working. I've read that there are some almond colored spray paints that do a good job of matching the IIc color. (e.g. https://www.amazon.com/dp/B0019K90FQ?smid=A4T86GQSLKK34) I'll have to find a different paint for my IIc plus LCD case when I get it produced. Should help protect it from the UV rays that break it down.Very smooth, looks nicer than extrusion printing, make sure you add a washer (nylon/plastic) in between the hinge part of the bezel where it meets the base (where the long M4 screw meets the bezel) id love to know what the print costs in total, and how the materials hold up over time, i would avoid sunshine directly on the display.

Got the screws and nylon washers in. I was able to get it to work, but I think using socket head cap screws made it harder. Basically, I had to insert the knobs in their holder with the hex key not fully pressed in, then rotate the knob while pushing the hex key in with tweezers until it was inserted into the hex head screw. Also, I only needed 35mm long screws, not sure if that is because of how I positioned my nut in the resin print I did. So far it is holding fine, although I do have to re-tighten after moving the screen up or down. I suspect that is just a factor of using a screw that will loosen when the screen is moved.

Anyway, here's some additional shots that hopefully will help others with their assembly.

The side pieces shouldn't be attached to the base until after the hex screw has been installed in the hinge. Once you have it installed and somewhat tightened, then you attach the sides using 3 3mm screws per side. Before inserting the screw, you should also install the nylon washers in between the hinge pieces.

After you've done that, take the hex key and insert it into the hex head screw, and mark the depth to the inside lip of the side piece. That should tell you roughly how much the hex key needs to stick out of the knob.

You can see in my picture, with the socket head cap screws, it didn't leave much sticking out. I think that is probably why I had a harder time inserting the knob into its holder. With a normal pan head screw, there would be more room and a longer hex key portion to insert it at an angle and then lower the knob into its holder. With mine, I was unable to insert it with the hex key fully protruding, so I pulled the hex key back out a bit, put the knob in it's slot on the side piece, then rotated the knob while pushing the hex key with tweezers. When the hex key aligned with the socket on the screw, it would allow itself to be pushed in to the correct depth. Adding the little slices that complete the knobs was helpful in holding the hex key at its correct depth. The superglued nuts seem to be holding, but I did take care not to over-tighten, going just enough to ensure there was friction to keep the screen at the current angle.

Anyway, here's the final result of the resin print:

Anyway, here's some additional shots that hopefully will help others with their assembly.

The side pieces shouldn't be attached to the base until after the hex screw has been installed in the hinge. Once you have it installed and somewhat tightened, then you attach the sides using 3 3mm screws per side. Before inserting the screw, you should also install the nylon washers in between the hinge pieces.

After you've done that, take the hex key and insert it into the hex head screw, and mark the depth to the inside lip of the side piece. That should tell you roughly how much the hex key needs to stick out of the knob.

You can see in my picture, with the socket head cap screws, it didn't leave much sticking out. I think that is probably why I had a harder time inserting the knob into its holder. With a normal pan head screw, there would be more room and a longer hex key portion to insert it at an angle and then lower the knob into its holder. With mine, I was unable to insert it with the hex key fully protruding, so I pulled the hex key back out a bit, put the knob in it's slot on the side piece, then rotated the knob while pushing the hex key with tweezers. When the hex key aligned with the socket on the screw, it would allow itself to be pushed in to the correct depth. Adding the little slices that complete the knobs was helpful in holding the hex key at its correct depth. The superglued nuts seem to be holding, but I did take care not to over-tighten, going just enough to ensure there was friction to keep the screen at the current angle.

Anyway, here's the final result of the resin print:

I see a nice competitor to the C64 laptop

Oh it seems some of the eyoyo have an RTD266x chip… those supposedly can be patched to support 15kHz RGB input, which I'll want for my ORICs…

Oh it seems some of the eyoyo have an RTD266x chip… those supposedly can be patched to support 15kHz RGB input, which I'll want for my ORICs…