... with rubbish soldering options in the prosumer space. Hakko used to be great, but they're leaning so hard into digital UI the wrong way - with buttons, not dials! Louis Rossman hilariously comments they have an "80s alarm clock approach" to setting temperature. And it's true. Their hot air stations require you to set temps digits by digit. The intuitive dial is dying!

But there is hope! We can have our digital cake and eat it, too, with stopless jog dials!

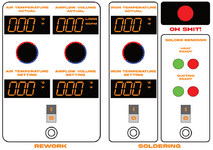

So I threw together this rough UI design, and wanted to see if any peeps wanted to put our skills together to prototype THE PERFECT HOBBYIST SOLDER STATION. I call it Lil' Hottie. I''m knowledgable with design and UI, also OK with fabrication. Electrical engineering, coding, etc... not really my strength.

Anyways, I did a quick mock up on what the perfect hobbyist station would look like. The red/blue border around the dials indicates ring lighting that goes from blue to red when reaching set temperature.

I thought of having the solder remover incorporated into the iron, but I think tip temperature sensing is a higher priority.

In case it isn't immediately clear, the big red button is an emergency power cutoff to the entire system. Why such devices don't ALL have that is beyond me.

BTW, no in-handle pumps for the rework portion. Piston compressors are the way to go. And I don't want to take shortcuts. Shortcuts are often taken when they aren't necessary, when there is plenty of margin to meet the cost. For example, this design has one high velocity variable pneumatic system, and one vacuum system. Could one piston in the middle of their need get things done? Sure, but it would be compromsing both functions. Yuck to that kind of design.

Am I missing anything? Tell me! Let's collectively make this dream come true!

But there is hope! We can have our digital cake and eat it, too, with stopless jog dials!

So I threw together this rough UI design, and wanted to see if any peeps wanted to put our skills together to prototype THE PERFECT HOBBYIST SOLDER STATION. I call it Lil' Hottie. I''m knowledgable with design and UI, also OK with fabrication. Electrical engineering, coding, etc... not really my strength.

Anyways, I did a quick mock up on what the perfect hobbyist station would look like. The red/blue border around the dials indicates ring lighting that goes from blue to red when reaching set temperature.

I thought of having the solder remover incorporated into the iron, but I think tip temperature sensing is a higher priority.

In case it isn't immediately clear, the big red button is an emergency power cutoff to the entire system. Why such devices don't ALL have that is beyond me.

BTW, no in-handle pumps for the rework portion. Piston compressors are the way to go. And I don't want to take shortcuts. Shortcuts are often taken when they aren't necessary, when there is plenty of margin to meet the cost. For example, this design has one high velocity variable pneumatic system, and one vacuum system. Could one piston in the middle of their need get things done? Sure, but it would be compromsing both functions. Yuck to that kind of design.

Am I missing anything? Tell me! Let's collectively make this dream come true!

Attachments

Last edited: