Earlier this year, a friend mentioned to me that he has had an Apple Lisa 2 in storage for many years, a machine that he acquired in the early 90s that had never worked properly for him. The symptoms, as he remembered them, was that the computer would turn on and run for a few minutes, and then turn off again. And sometimes it wouldn't turn on at all. In addition, it had suffered battery leak damage in storage, although it had been caught relatively early, luckily, with the battery removed some years prior. He casually mentioned that I could take a look at it and assess the damage, if I'd like to.

At that point, I had a track record of fixing a fair number of vintage computers in various stages of disrepair, but a battery damaged Lisa with other known issues would definitely be my biggest project yet, and on a really quite expensive/valuable piece of equipment to boot. This is a computer of which between 10,000 and 80,000 (depending on the source of the estimates) were ever sold, after all. I hesitated at first, and told him that I could look at it some day, but made no promises beyond that.

Then one day, after I had helped him fix another few computers of his for fun (Apple ][+, //gs, Mac 128k, and a few peripherals) we agreed that it was time to look at that Lisa. We pulled the old girl out of storage and lugged her over to my friend's apartment. Her profile may be low when viewed from the front, but she has a hefty backside. All those solid steel frames in there makes for one heavy piece of equipment!

Before proceeding further, I decided that it was time to assess the battery damage for starters.

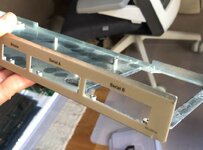

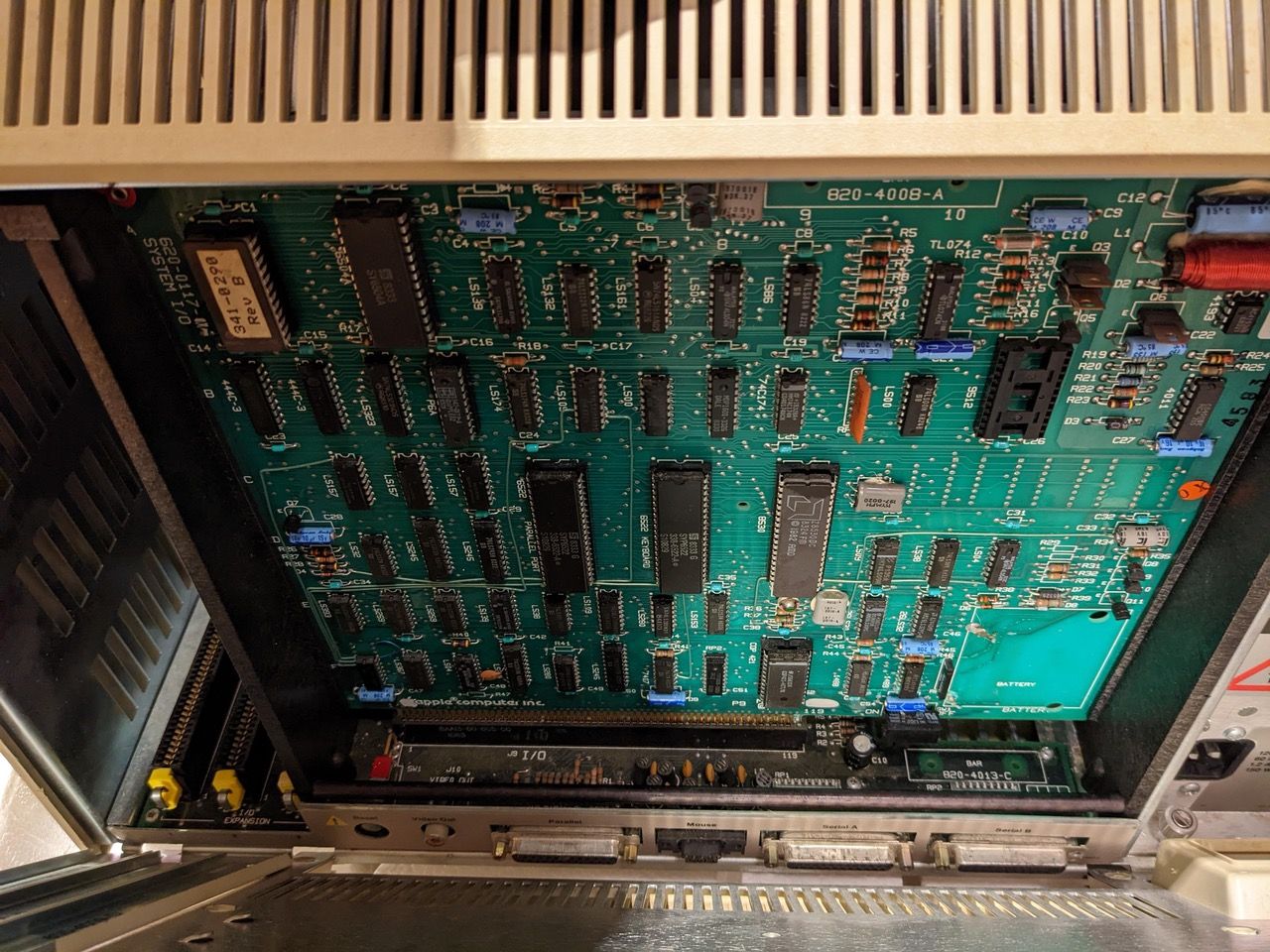

All of the main logic circuitry of the Lisa sits inside of a conveniently located card cage just behind the back panel of the computer. The battery used to sit on the I/O board, which is the outermost card in the card cage.

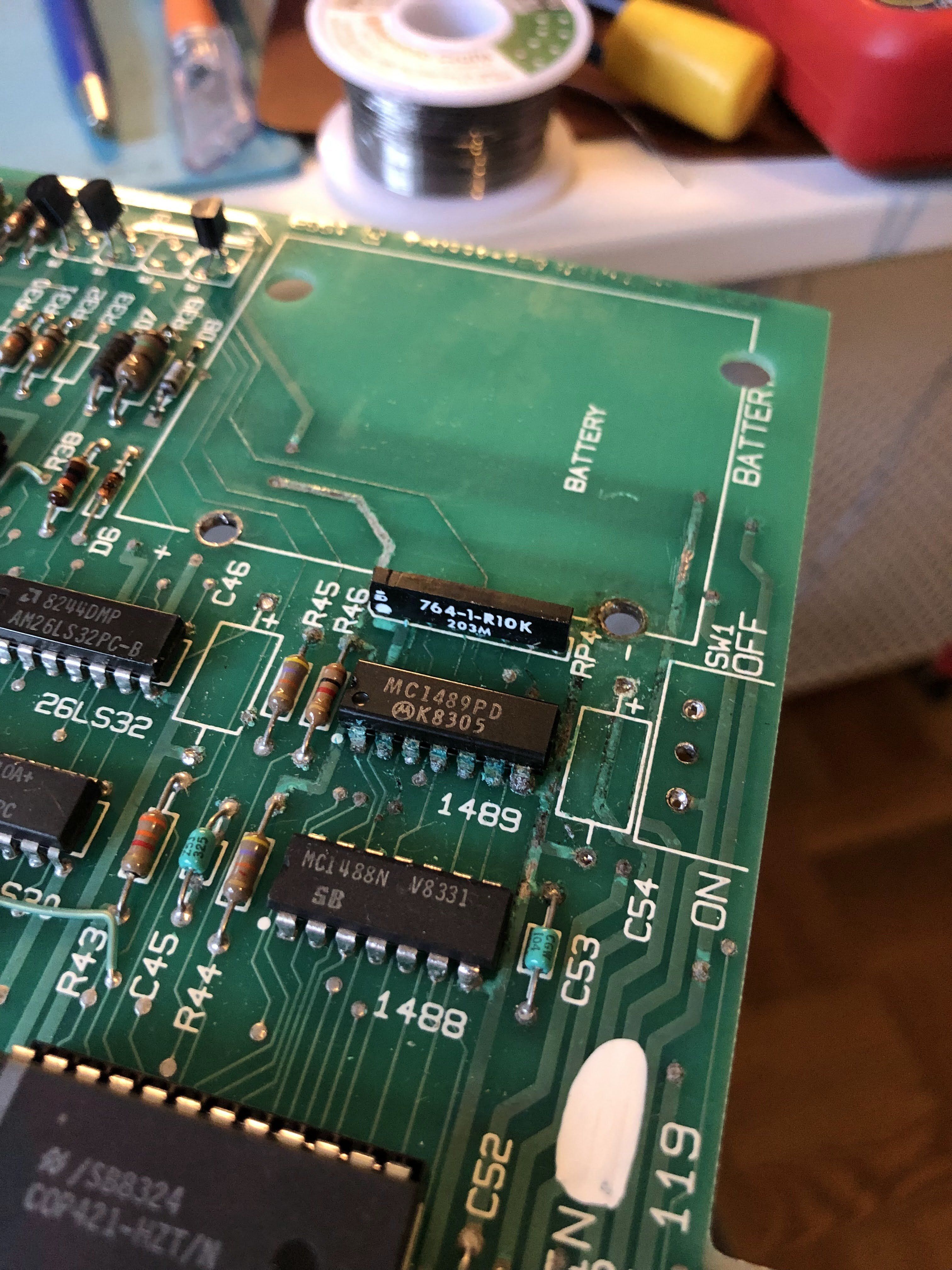

Off the bat, the battery juice had clearly caused some damage to traces and components, but luckily it was fairly well isolated on this particular board. The most green crust could be found on the Motorola 1489 chip, but otherwise mostly on traces and solder joints. Pretty nasty, but manageable! (We did run into a bit of a surprise though; more on this later.)

Moving on to the Motherboard (yes, this is what Apple calls it on the silk screen and in documentation!)

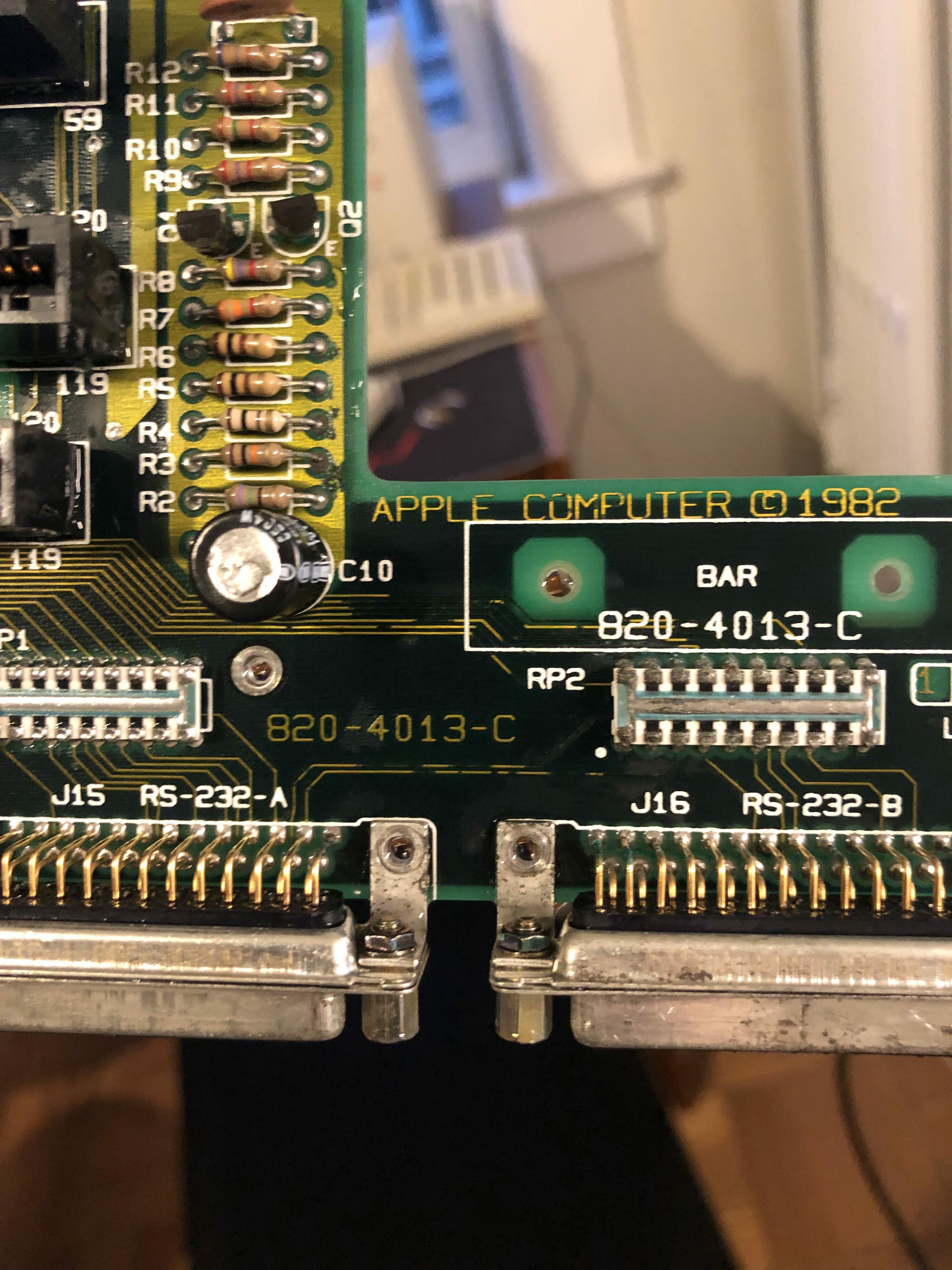

On the left hand side of this board we had some very sad looking traces, as well as a very very crusty (and weird-looking) resistor pack. This picture just quite don't convey just how dull all of the joints of RP2 was -- they looked more like granite than solder.

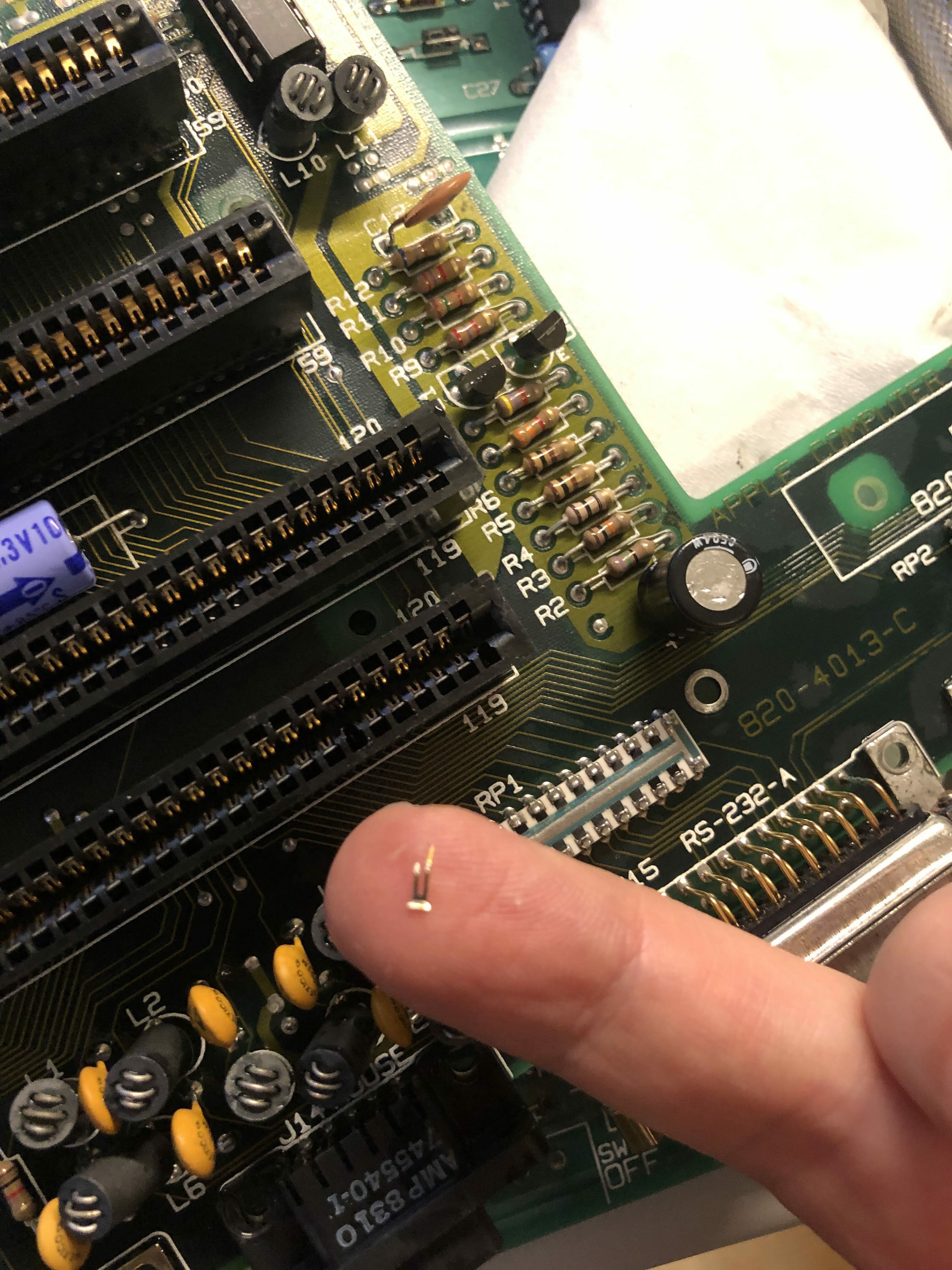

Then moving on to the 120 pin socket that the I/O board sits in on the Motherboard, we had more of that green crust that made its way into the socket. I didn't take a before picture, but here is just after neutralizing it with vinegar. Just gently poking on the pins made them fall off. Rotten at the root. This socket needs to go!

There was also a bit of green corrosion on the edge connectors on the upper side of the Motherboard that I didn't snap a picture off, as well as in the slots leading to the Video board and Lite board (disk drive adapter.) Luckily, it could be neutralized and scraped off without further damage.

At this stage of the process, I put in an order with Mouser for replacement parts of clearly damaged components, and took a break while waiting for the shipment to arrive. In the next post, I will address the battery damage and take one step closer to a working computer!

At that point, I had a track record of fixing a fair number of vintage computers in various stages of disrepair, but a battery damaged Lisa with other known issues would definitely be my biggest project yet, and on a really quite expensive/valuable piece of equipment to boot. This is a computer of which between 10,000 and 80,000 (depending on the source of the estimates) were ever sold, after all. I hesitated at first, and told him that I could look at it some day, but made no promises beyond that.

Then one day, after I had helped him fix another few computers of his for fun (Apple ][+, //gs, Mac 128k, and a few peripherals) we agreed that it was time to look at that Lisa. We pulled the old girl out of storage and lugged her over to my friend's apartment. Her profile may be low when viewed from the front, but she has a hefty backside. All those solid steel frames in there makes for one heavy piece of equipment!

Before proceeding further, I decided that it was time to assess the battery damage for starters.

All of the main logic circuitry of the Lisa sits inside of a conveniently located card cage just behind the back panel of the computer. The battery used to sit on the I/O board, which is the outermost card in the card cage.

Off the bat, the battery juice had clearly caused some damage to traces and components, but luckily it was fairly well isolated on this particular board. The most green crust could be found on the Motorola 1489 chip, but otherwise mostly on traces and solder joints. Pretty nasty, but manageable! (We did run into a bit of a surprise though; more on this later.)

Moving on to the Motherboard (yes, this is what Apple calls it on the silk screen and in documentation!)

On the left hand side of this board we had some very sad looking traces, as well as a very very crusty (and weird-looking) resistor pack. This picture just quite don't convey just how dull all of the joints of RP2 was -- they looked more like granite than solder.

Then moving on to the 120 pin socket that the I/O board sits in on the Motherboard, we had more of that green crust that made its way into the socket. I didn't take a before picture, but here is just after neutralizing it with vinegar. Just gently poking on the pins made them fall off. Rotten at the root. This socket needs to go!

There was also a bit of green corrosion on the edge connectors on the upper side of the Motherboard that I didn't snap a picture off, as well as in the slots leading to the Video board and Lite board (disk drive adapter.) Luckily, it could be neutralized and scraped off without further damage.

At this stage of the process, I put in an order with Mouser for replacement parts of clearly damaged components, and took a break while waiting for the shipment to arrive. In the next post, I will address the battery damage and take one step closer to a working computer!

Last edited: