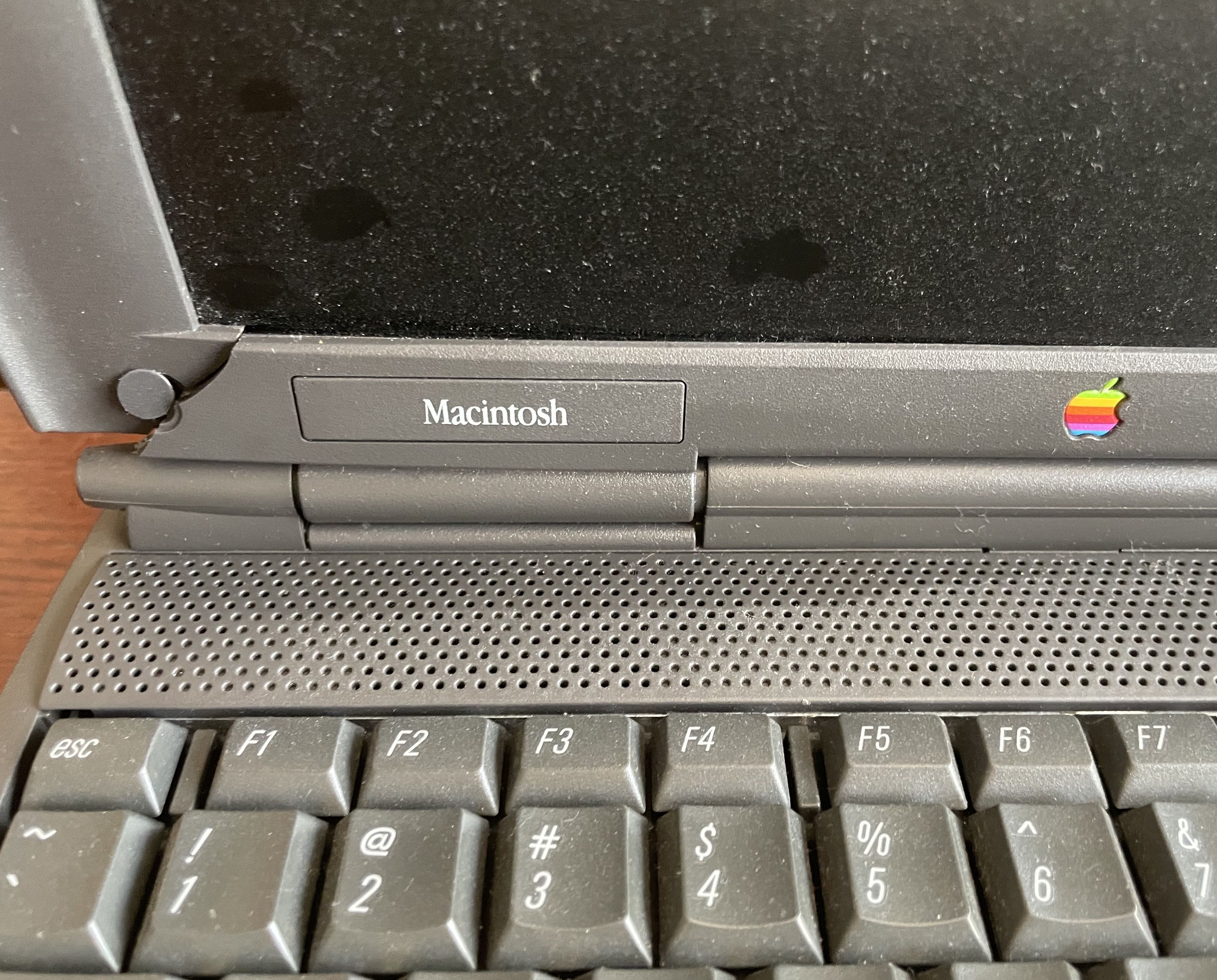

Congratulations: You officially win the award for the worst cracked 1400 display housing! That is truly remarkable.

You have a few options here.

The 1400's hinge failures are twofold:

1. As ClassicHasClass described, the hinge mounts can break. This sort of failure can and does happen to nearly every 90s laptop at this point... it's bad.

2 (and this is the real 1400 killer). The rear housing itself stress cracks and eventually with enough time... well... you can see what happens. This failure usually happens independently to the first issue, although the first issue certainly can accelerate this one. At this point in time, due to how fragile the plastic has become, this problem will happen to 100% of 1400s if the hinges are used. A perfect one will be perfect for at most 20 hinge cycles before you see the cracks starting.

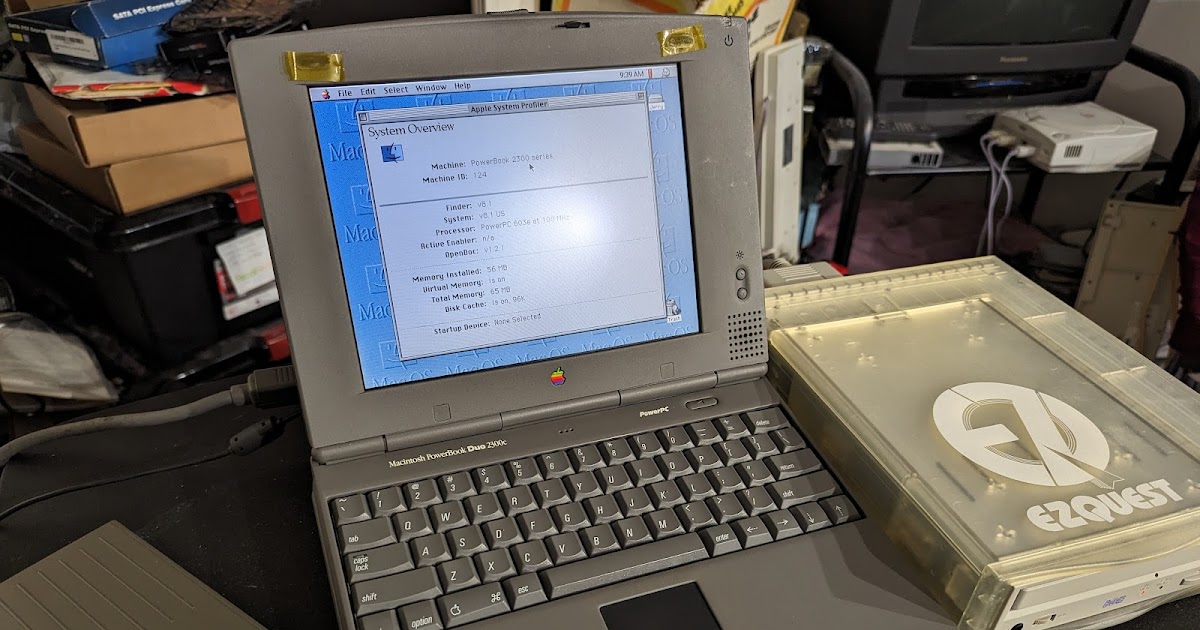

I recently went on a long restoration project on a couple of 1400s, which I documented here:

https://68kmla.org/bb/index.php?threads/powerbook-1400c-166-restoration-combination-thread.44820/

As part of this process, I went ahead and attempted to reinforce the plastic around the hinges with this 3D printed hinge fix:

https://68kmla.org/bb/index.php?threads/powerbook-1400-hinge-fix-shim.39921/

You can see the process to install it in my units in my restoration thread. As you'll see, it's a very frustrating and difficult one.

Unfortunately, it has not prevented the issue in my units. I installed the parts in 2 different units. One that was just starting to crack, and another that was 100% intact. I've been using the intact one with excellent non-stiff hinges like a normal laptop (not concerned about not using the hinges) since then for retro stuff, and I've just recently noticed a tiny crack starting on the left side. So, it isn't a fix. At best, it slows things down.

From the guy who created it though, it's likely that it would function as a fix if you already had bad cracks that you patched up with epoxy. It likely won't prevent damage from starting though.

I heard another guy say that he used wood filler to reinforce his 1400. They said that they applied a bunch of it all in the housing, placed plastic wrap over it, then reinstalled the LCD and other parts to make a mold. Says this has worked for them so far, but I haven't tried it yet myself though.

My experiments with the 3D printed parts failing doesn't bother me much. Neither of my housings were in good cosmetic shape anyway, so no pristine parts were lost. I'm just trying to see what works and what doesn't.

There was another thread over on 68kMLA a while back on the possibility of manufacturing new parts. We determined that it would be too expensive for the expected number that would likely sell.

------------------------------------------------------------------------------------------------

So, with the current state of your parts, I'd just recommend finding a donor unit. Your parts are pretty bad. Once you do though? All you can really do is experiment and see what works and what doesn't. No one's figured out a foolproof way to fix these cracking issues yet. It's an issue that befalls many models of laptops from this time, far more than just the 1400. We're actually pretty lucky that the 1400 is the only severely effected PowerBook.

What will usually work is copious amounts of epoxy of some sort

after it's cracked. That however, is pretty ugly.