Yeah HTPLA is kinda interesting. For me personally the 2x the price of PETG and ABS and the need to do the extra step post heat treating are not necessary for this application. If I needed something over 100C it would probably be the best choice for ease of printing.

Carbon fiber adds even more to the price of the plastic. It's also is highly recommended to use a wear resistant nozzle (additional cost and installation) to prevent destroying your printer's nozzle over time.

For printing the bracket on a FDM printer I'd still suggest printing with ABS/ASA if possible or use PETG. At a glass transition temperature of around ~80C, PETG should be more than enough for the clip.

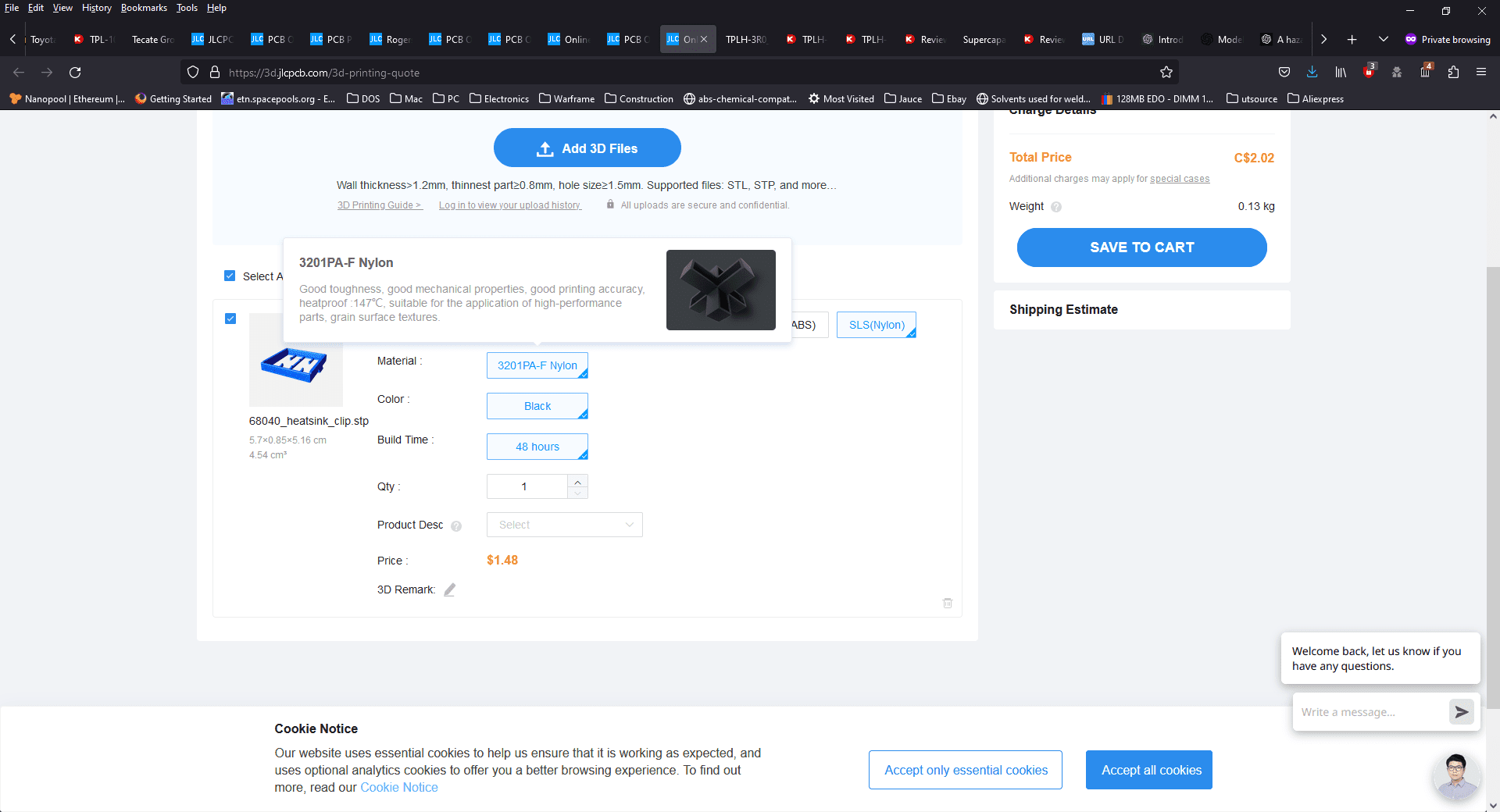

If you're just going to use a third party to print it for you then might as well go with an superior industrial SLS printer and material if the price is reasonable.

For FDM printing PETG has other properties that make it goo for the forces involved in the application of a heatsink clip. PETG has excellent strength and flexibility without breaking or deforming. When I designed the heating clip I into account. Let's take a look at this picture:

The red circles are providing downward force onto the heatsink and CPU is providing and upward force against the clips circles in green.

The torque applied to clips in the green circles don't have much leverage so are unlikely to break. The walls of the clip are also thick to prevent them from bowing (that's not the only reason they won't bow easily), which if they could, could also allow the green clips to detach from the CPU. The wall thickness of the clip also helps prevent permanent deformation of the clip when installing and removing the clip.

Now the the downward force of the red point result in torque being applied at the where these levers attach to the heatsink represented by the small blue circles. These points are the most likely to deform/break. PETG being strong and flexible will prevent this from happening as long as there's continuous strands of plastic perpendicular to the force. So the orientation of printing the part on an FDM printer is for just for ease of printing, It's maximize the strength at points of stress.

Now you have noticed that the middle has a continuous strip of plastic unlike the other 4 smaller levers. This is to provide additional downward force in the middle of the heatsink is (since the die is there) through tension along with torque resistance. This also makes it very hard to snap at the ends.

You may be asking why I didn't do continuous strips for all of them if it's superior. Well, plastic is also an insulator so I'd like to cover as little as possible of the heatsink's surface to allow better heat dissipation.

Regarding heat concerns, the hottest part of the CPU will at the center of the CPU. The points of contact there are the red dots in picture which are small to help prevent direct heat transfer. If 60C is the max temperature when overclocking with a fan it should be fine.

Well that ended up being rather long, but I felt like talking a bit about the design decisions I make when I design a 3D printable part.