I have seen several examples of using CR2032 battery holders as replacements for dead half-AA on compact Macs. Using this type of battery has been working fine for me on the SE/30, SE, Mac Classic, and I assume there are other systems that can use this solution as well. This is not news to most of you—as I have seen plenty of others doing this on YouTube and elsewhere.

How exactly you go about attaching the CR2032 holder is up to you, but for the compact Mac models I have, clearance of the horizontal chassis struts is a requirement. Another requirement for me is to avoid precarious support. I want to be able to press the disc battery to snap it into place without collapsing the soldered wire connections to the board—since the holder itself is too wide to fit into the battery location and sit flat onto the circuit board. I also want to avoid a flexible wired solution that requires me to attach the holder somewhere with double-stick tape or something.

I have two solutions:

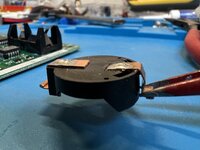

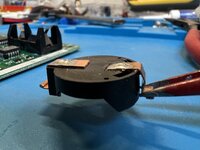

1. Add two simple, bent copper strips to the holder so it fits into the EXISTING half-AA holder where applicable (SE/30, Classic)

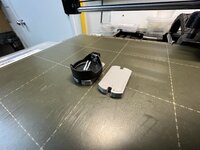

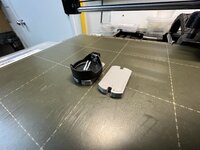

2. Extend the legs of a CR2032 holder and perch it atop a 3d-printed spacer to clear the surrounding chips on the board (SE)

The first solution is intended to leave the existing holder intact. You may even be able to slip the plastic “cage” part over the top of the CR2032 to hold it in, and strategic bends in the copper help to create a spring-friction fit that is unlikely to come out.

For the second solution, the spacer sits under the holder, captured by the extended legs. While it is just loosely underneath the holder, it is not rattling around if you solder the holder down with thumb pressure. Crucially, the holder now clears the tops of surrounding components while not causing any clearance issues with the chassis. Finally, the spacer supports the slight pressure you exert when inserting a disc battery:

Attached is a zip file containing the STL file I created for this simple spacer. I printed at lowest reslolution and 100% infill, but whatever works best for you is fine.

I will continue to use both of these techniques were component clearance is needed, or where an existing holder is perfectly intact and all I need is to adapt it to the CR2030 form factor.

How exactly you go about attaching the CR2032 holder is up to you, but for the compact Mac models I have, clearance of the horizontal chassis struts is a requirement. Another requirement for me is to avoid precarious support. I want to be able to press the disc battery to snap it into place without collapsing the soldered wire connections to the board—since the holder itself is too wide to fit into the battery location and sit flat onto the circuit board. I also want to avoid a flexible wired solution that requires me to attach the holder somewhere with double-stick tape or something.

I have two solutions:

1. Add two simple, bent copper strips to the holder so it fits into the EXISTING half-AA holder where applicable (SE/30, Classic)

2. Extend the legs of a CR2032 holder and perch it atop a 3d-printed spacer to clear the surrounding chips on the board (SE)

The first solution is intended to leave the existing holder intact. You may even be able to slip the plastic “cage” part over the top of the CR2032 to hold it in, and strategic bends in the copper help to create a spring-friction fit that is unlikely to come out.

For the second solution, the spacer sits under the holder, captured by the extended legs. While it is just loosely underneath the holder, it is not rattling around if you solder the holder down with thumb pressure. Crucially, the holder now clears the tops of surrounding components while not causing any clearance issues with the chassis. Finally, the spacer supports the slight pressure you exert when inserting a disc battery:

Attached is a zip file containing the STL file I created for this simple spacer. I printed at lowest reslolution and 100% infill, but whatever works best for you is fine.

I will continue to use both of these techniques were component clearance is needed, or where an existing holder is perfectly intact and all I need is to adapt it to the CR2030 form factor.

Attachments

Last edited: