I have the other revision that has composite video on, but I'm hoping the button control board is the same. But it does look like there are a bunch of different variants of the same controller boards. I even found this one which would be cool for my SE inspired LCD panel - a ton of inputs in an easily mountable form factor: https://www.ebay.com/itm/2269545937...eIs_Xj6R-FO4BRyoedhzPBtT9kiitqkVjgUKrHX1ZtRj4I just picked up a Creality CR10 v2 from FB marketplace this morning... so running a first test print it may not be suitable until further testing. My Ender 3 Pro will only print to 8" so it is not wide enough to print as a single piece.

I will try to print the full piece this week in Platinum and see how it goes.

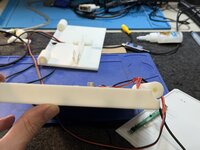

View attachment 24593

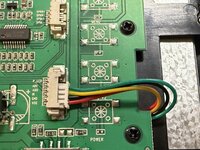

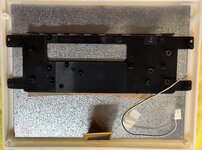

@wottle , one thing you will have to check is if the control panel buttons line up with the "back" of the LCD cover, it may need some adjustment. Most of these controller boards are very similar, but it might be just enough off to not fit correctly. There is currently no internal mounting holes for the video board itself, so you may have to resort to double-sided foam tape to hold the driver board to the back of the iPad screen. I will measure my board and add some mounts on the back panel for it before I print it.

My particular iPad driver only has VGA and HDMI inputs, no composite. My Eyoyo 8" has VGA, HDMI, and composite inputs.

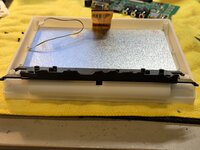

View attachment 24594

I'm still hoping to squeeze in a buck converter off the USB-C trigger board so basically I'll have this:

Code:

/--- 15v ---> internal buck converter (12v) --- 12v ---> LCD board

---> USB-C Trigger (15v) -<

\--- 15v ---> external Apple IIc connector to power computerSo the LCD enclosure will have a single USB-C input for powering both the LCD and the Apple IIc, with two cables coming out (one going to power the IIc and one that has an RCA plug for composite video.

However, I actually checked the current being pulled for my 10" iPad screen off the monitor output line and it is pulling a bit over 400mA and I haven't run into problems. Given the 8" Eyoyo pulls less than that, I may go back to my original plan of having the pull power and composite from the video out port. That would allow me to have the LCD always plugged in with a single cable, and I could power the IIc from my usb-c power adapter. It achieves my main goal of not having to have multiple USB-C cables to power everything.