I needed a programmer's switch for my Macintosh SE/SpeedCard and looked around for a vintage one, but ended up getting a new MacEffects Clear Programmer's Switch.

I decided against using a vintage switch because, even when they were new, they were somewhat brittle and lost clips under mild strain (albeit often because of mishandling...but..). Now, that the plastic has aged, it is potentially even more of a liability. Also, the vintage switches are significantly overpriced. So, why pay more for old, fragile part with polymer degradation just for the sake of appearance? No thanks. I need one that is strong, functional, reliable and that will stand up to regular use.

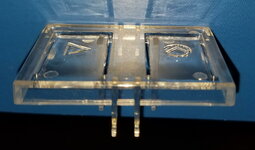

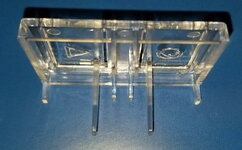

Attached are some pictures of the @MacEffects clear SE switch - it looks good, seems well-made and works great! There was a slight tolerance issue between the switch prongs and the gaps in the MacSE's lower ventilation slots - both switch prongs got stuck/wedged in the gap when pressing the buttons. To fix this issue, I lightly sanded the related SE case openings (on ventilation slots #5 and #8 - counting from the back edge). I removed a couple mils of material on either side and that fixed the tolerance problem. I am happy to have slightly thicker (stronger) prongs and the minimal case sanding is an imperceptible change. The reset switch snapped perfectly into place.

See the attached pictures.

Anyway - I recommend this product, albeit with the (reasonable) caveat of required case sanding to very slightly enlarge the ventilation slots. Now, I can successfully disable my SpeedCard!

MacEffects ships First Class in the US (cheapest), so the cost was $15 + $5.38 shipping. Also, their customer service was very responsive and helpful!

I decided against using a vintage switch because, even when they were new, they were somewhat brittle and lost clips under mild strain (albeit often because of mishandling...but..). Now, that the plastic has aged, it is potentially even more of a liability. Also, the vintage switches are significantly overpriced. So, why pay more for old, fragile part with polymer degradation just for the sake of appearance? No thanks. I need one that is strong, functional, reliable and that will stand up to regular use.

Attached are some pictures of the @MacEffects clear SE switch - it looks good, seems well-made and works great! There was a slight tolerance issue between the switch prongs and the gaps in the MacSE's lower ventilation slots - both switch prongs got stuck/wedged in the gap when pressing the buttons. To fix this issue, I lightly sanded the related SE case openings (on ventilation slots #5 and #8 - counting from the back edge). I removed a couple mils of material on either side and that fixed the tolerance problem. I am happy to have slightly thicker (stronger) prongs and the minimal case sanding is an imperceptible change. The reset switch snapped perfectly into place.

See the attached pictures.

Anyway - I recommend this product, albeit with the (reasonable) caveat of required case sanding to very slightly enlarge the ventilation slots. Now, I can successfully disable my SpeedCard!

MacEffects ships First Class in the US (cheapest), so the cost was $15 + $5.38 shipping. Also, their customer service was very responsive and helpful!