I'm frustrated.

Finally have everything to bring my PowerBook 165 back to life: Recapped LCD and inverter board, new power supply, J-B Welded hinge screw posts on the lid (plus two spare 3D-printed post assemblies, just in case.) I decided to spend this morning trying to put it all back together, despite another issue I ran into which I'll discuss a tad later.

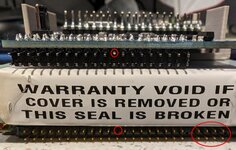

The flat-flex LCD ribbon cable was being a major pain while attempting to reassemble the machine. I finally got it connected and adhered to the backside of the LCD assembly, but the ribbon cable kept flexing while attempting to fasten the screws on the LCD. (Didn't help my screwdriver bit kept falling out.) While connecting the inverter cabling connectors, somehow my fear came true — the ribbon cable broke right in half. I was trying to be gentle to avoid from that.

Does anyone here have a replacement ribbon cable, or is there anywhere you can purchase a replacement? What is the best way to replace it, since it seemed to keep twisting and had a lot of tension earlier?

On a slight tangent, I've had a couple other failures with this project. I'm trying to get a BlueSCSI configured for this machine.

Using Disk Jockey, I created a 500 MB volume on the microSD card. I'd like to install System 7.5.3 on the volume using Basilisk II (since I don't have any floppies to put the install images on), but Basilisk II won't open the .hda file from the setup GUI. Dragging it in, System 7.5.3 will prompt for the volume to be initialized. However, it won't let me initialize it because "the disk is locked." The image isn't locked. Is there something I'm missing?

I'm also trying to update the firmware on the BlueSCSI to enable WiFi modem emulation. I connected the BlueSCSI's Raspberry Pi using a cheap microUSB cable to my Mac mini, and tried dropping the UF2 file into the 'RPI-RP2' drive. (The cable appears to have the usual four connections on both ends, and I believe I may have used it to transfer data before.) It ejected but never automatically restarted, and the activity LED never blinked. Upon restart the activity LED very briefly blinks while connected to the Mac. I removed the SD card to see if I could find a 'log.txt' file on it. I never saw it. I did, however, find a 'err.txt' file on the first attempt, which I took a screenshot of. While subsequent attempts yielded the same failure, I never got another 'err.txt' file, but also never got a 'log.txt' file. Does this sound like an issue with my USB cable, or is there something else possibly happening here?

Hopefully I can get all this sorted out, because I contemplated just giving up after the cable snapped. As always, any help would be greatly appreciated.

Finally have everything to bring my PowerBook 165 back to life: Recapped LCD and inverter board, new power supply, J-B Welded hinge screw posts on the lid (plus two spare 3D-printed post assemblies, just in case.) I decided to spend this morning trying to put it all back together, despite another issue I ran into which I'll discuss a tad later.

The flat-flex LCD ribbon cable was being a major pain while attempting to reassemble the machine. I finally got it connected and adhered to the backside of the LCD assembly, but the ribbon cable kept flexing while attempting to fasten the screws on the LCD. (Didn't help my screwdriver bit kept falling out.) While connecting the inverter cabling connectors, somehow my fear came true — the ribbon cable broke right in half. I was trying to be gentle to avoid from that.

Does anyone here have a replacement ribbon cable, or is there anywhere you can purchase a replacement? What is the best way to replace it, since it seemed to keep twisting and had a lot of tension earlier?

On a slight tangent, I've had a couple other failures with this project. I'm trying to get a BlueSCSI configured for this machine.

Using Disk Jockey, I created a 500 MB volume on the microSD card. I'd like to install System 7.5.3 on the volume using Basilisk II (since I don't have any floppies to put the install images on), but Basilisk II won't open the .hda file from the setup GUI. Dragging it in, System 7.5.3 will prompt for the volume to be initialized. However, it won't let me initialize it because "the disk is locked." The image isn't locked. Is there something I'm missing?

I'm also trying to update the firmware on the BlueSCSI to enable WiFi modem emulation. I connected the BlueSCSI's Raspberry Pi using a cheap microUSB cable to my Mac mini, and tried dropping the UF2 file into the 'RPI-RP2' drive. (The cable appears to have the usual four connections on both ends, and I believe I may have used it to transfer data before.) It ejected but never automatically restarted, and the activity LED never blinked. Upon restart the activity LED very briefly blinks while connected to the Mac. I removed the SD card to see if I could find a 'log.txt' file on it. I never saw it. I did, however, find a 'err.txt' file on the first attempt, which I took a screenshot of. While subsequent attempts yielded the same failure, I never got another 'err.txt' file, but also never got a 'log.txt' file. Does this sound like an issue with my USB cable, or is there something else possibly happening here?

Hopefully I can get all this sorted out, because I contemplated just giving up after the cable snapped. As always, any help would be greatly appreciated.