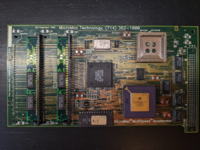

Here's the steps I took with the MultiSpeed accelerator in the SE today:

First, I moved all four SIMMs on the accelerator to different slots. My thinking was that if one of the SIMMs was bad, I would get a different range in the error message than "D7 - D0". The error message remained the same.

Then, I did as @Trash80toG4 suggested and installed all four SIMMs from the accelerator into the SE's logic board and booted the system without the accelerator installed. It booted fine.

At this point, I was convinced that the problem was with the accelerator board itself and not a bad SIMM.

I then reflowed all of my solder joints on the accelerator's new capacitors. Same error: "ERROR SIMM D7 - D0"

Then, I removed all four SIMMs from the accelerator and cleaned the SIMM slots and the SIMMs' contacts with 99.9% alcohol. After letting it dry and reinstalling everything, now the accelerator apparently can't see TWO of the SIMMs:

I then tried reordering the SIMMs on the accelerator again, but the errors remain the same.

So, that's where I'm at. I don't know if two of the SIMM slots aren't making good contact with their SIMMs or what. The addition of the "D15 - D8" error after cleaning and reseating suggests a mechanical issue with that slot, but I suppose the "D7 - D0" error that's been there from the start could be a deeper problem (worn trace, bad component, etc). That kind of stuff is beyond my ability to diagnose.

First, I moved all four SIMMs on the accelerator to different slots. My thinking was that if one of the SIMMs was bad, I would get a different range in the error message than "D7 - D0". The error message remained the same.

Then, I did as @Trash80toG4 suggested and installed all four SIMMs from the accelerator into the SE's logic board and booted the system without the accelerator installed. It booted fine.

At this point, I was convinced that the problem was with the accelerator board itself and not a bad SIMM.

I then reflowed all of my solder joints on the accelerator's new capacitors. Same error: "ERROR SIMM D7 - D0"

Then, I removed all four SIMMs from the accelerator and cleaned the SIMM slots and the SIMMs' contacts with 99.9% alcohol. After letting it dry and reinstalling everything, now the accelerator apparently can't see TWO of the SIMMs:

I then tried reordering the SIMMs on the accelerator again, but the errors remain the same.

So, that's where I'm at. I don't know if two of the SIMM slots aren't making good contact with their SIMMs or what. The addition of the "D15 - D8" error after cleaning and reseating suggests a mechanical issue with that slot, but I suppose the "D7 - D0" error that's been there from the start could be a deeper problem (worn trace, bad component, etc). That kind of stuff is beyond my ability to diagnose.