Restoration: Macintosh SE with Water Damage

- Thread starter PotatoFi

- Start date

-

Hey Guest, MARCHintosh 2026 is upon us. Check out community projects, join GlobalTalk, and have fun!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This was delightful. Thanks for all the detail, in both text and pics

Thanks! I enjoy writing these posts, and I hope that they encourage other people preserve vintage tech instead of trashing it, and maybe even serve as a guide to their own restoration projects.

Excellent! So happy to see it alive again.

Me too! I really didn't have much hope for this one. At first, it looked pretty hopeless, but the more I scrubbed and cleaned, the more hopeful I got.

Wow, nicely done! I'm curious about the screen burn-in, any idea what application it's from?

That's a really good question! I'll get back to you on this one.

At this stage, the machine powers on, boots from an external floppy, and all of the ports seem to work. I decided to keep going and see what else I could improve. Case was clean, but I had some sunny and hot days coming up; the perfect opportunity for some retrobrite! While I did scrub the case down earlier, I didn't really detail it. There are still some rust stains, black marks, and grimy corners to deal with. I discharged the CRT and disconnected the anode wire, and went to work with the impact driver. And speaking of the impact driver, I've been using it a LOT on this project. I think it will become a main part of how I work on these going forward. It makes teardowns super fast.

A couple of minutes later, it looked like this:

Before retrobrite in the sun, it's important to remove the Apple badge. If not, the heat and direct sun can bleach out the red and yellow colors. To remove it, carefully push something through the hole in the back. Be careful though, something sharp like this needle can poke through the paint in the badge. No trouble here, but just something to watch for. Normally I use a paperclip but the hole was too small.

Next, it was time to remove this stubborn "Property of the State of Idaho" sticker. I see a LOT of these stickers - pretty much every Mac I've bought locally bears one. Unfortunately, this one is too damaged to leave on.

I carefully got under it with a razor blade.

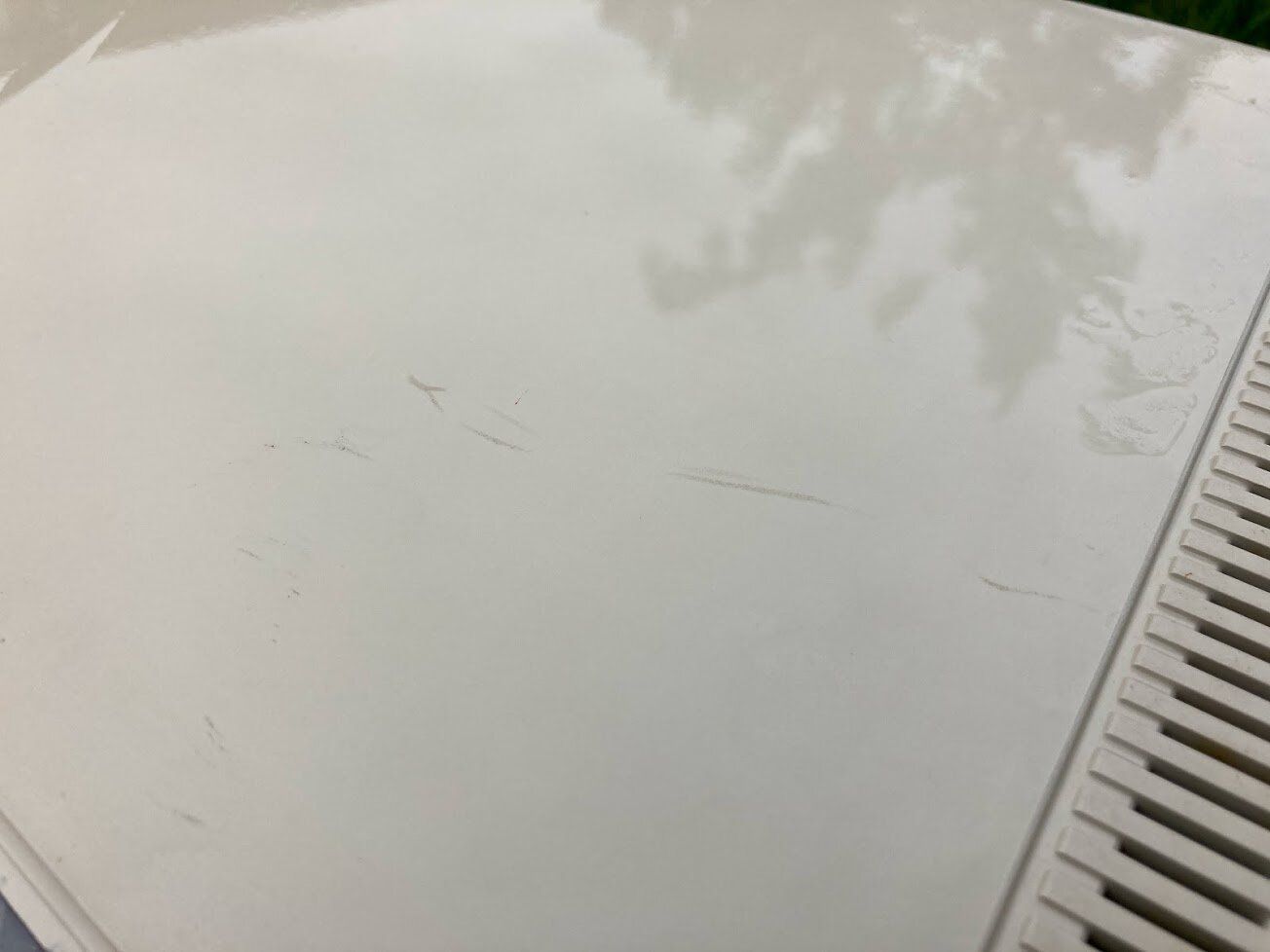

Hrm, a couple of new scratches... but worth it, I think.

To finish removing the sticker, I attacked the residue with some Goo-Gone.

Last edited:

With the sticker all taken care of, it was time to take the case outside for a final cleaning. I used my old standby: Dawn dishwasher detergent and a toothbrush.

For stubborn marks and scuffs, I used baking soda on a wet paper towel like before. There wasn't a single surface on the Mac that didn't need to work with the baking soda!

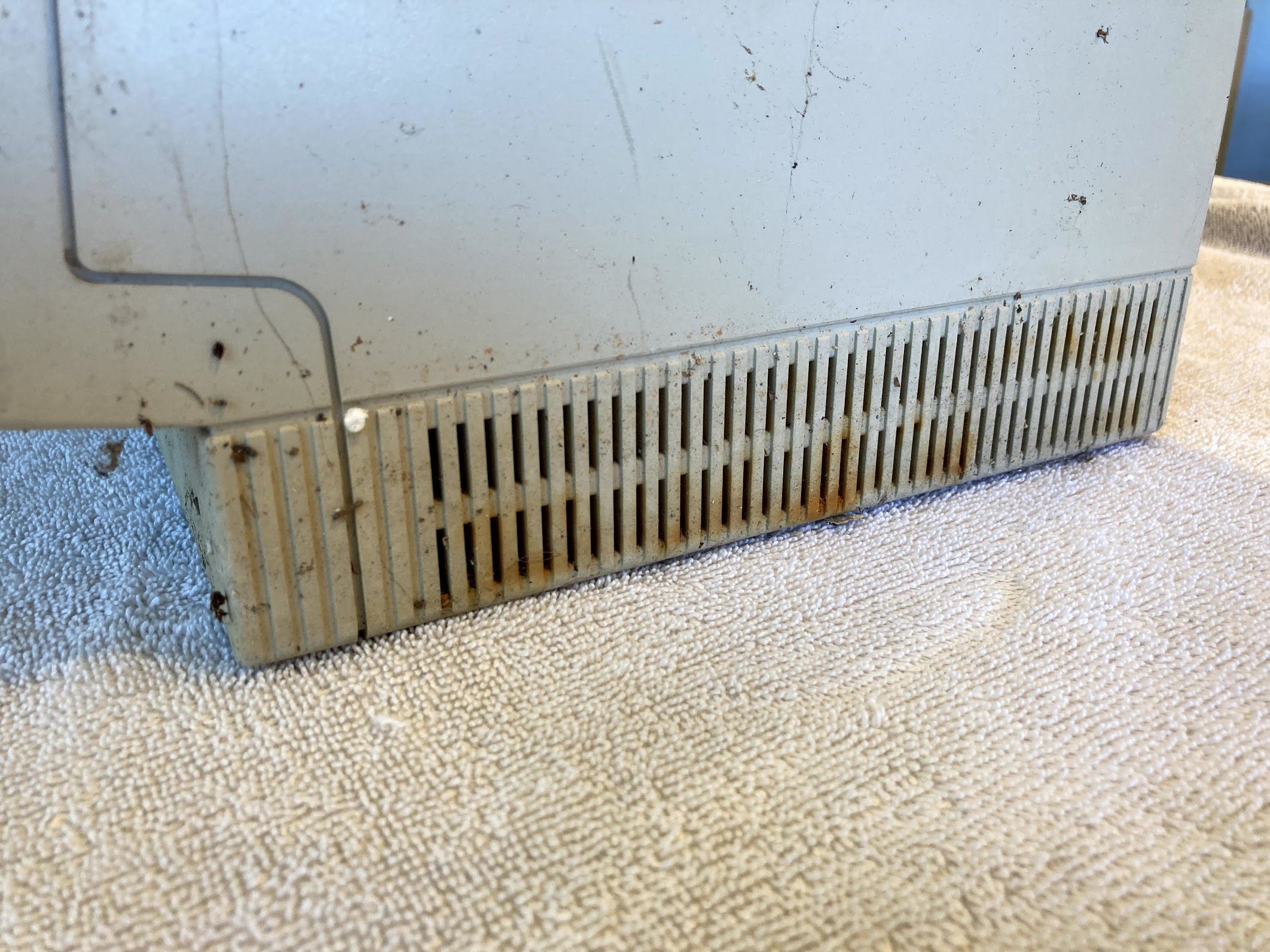

As a reminder, here's what the rust stains looked like before I went crazy with baking soda:

And here's what the Mac looked like after a good cleaning!

On the inside, there's still some rust stains...

...but I am pretty happy with how this machine is starting to look!

For stubborn marks and scuffs, I used baking soda on a wet paper towel like before. There wasn't a single surface on the Mac that didn't need to work with the baking soda!

As a reminder, here's what the rust stains looked like before I went crazy with baking soda:

And here's what the Mac looked like after a good cleaning!

On the inside, there's still some rust stains...

...but I am pretty happy with how this machine is starting to look!

Last edited:

Time for retrobrite! Here's what the Mac looked like at the beginning of the day.

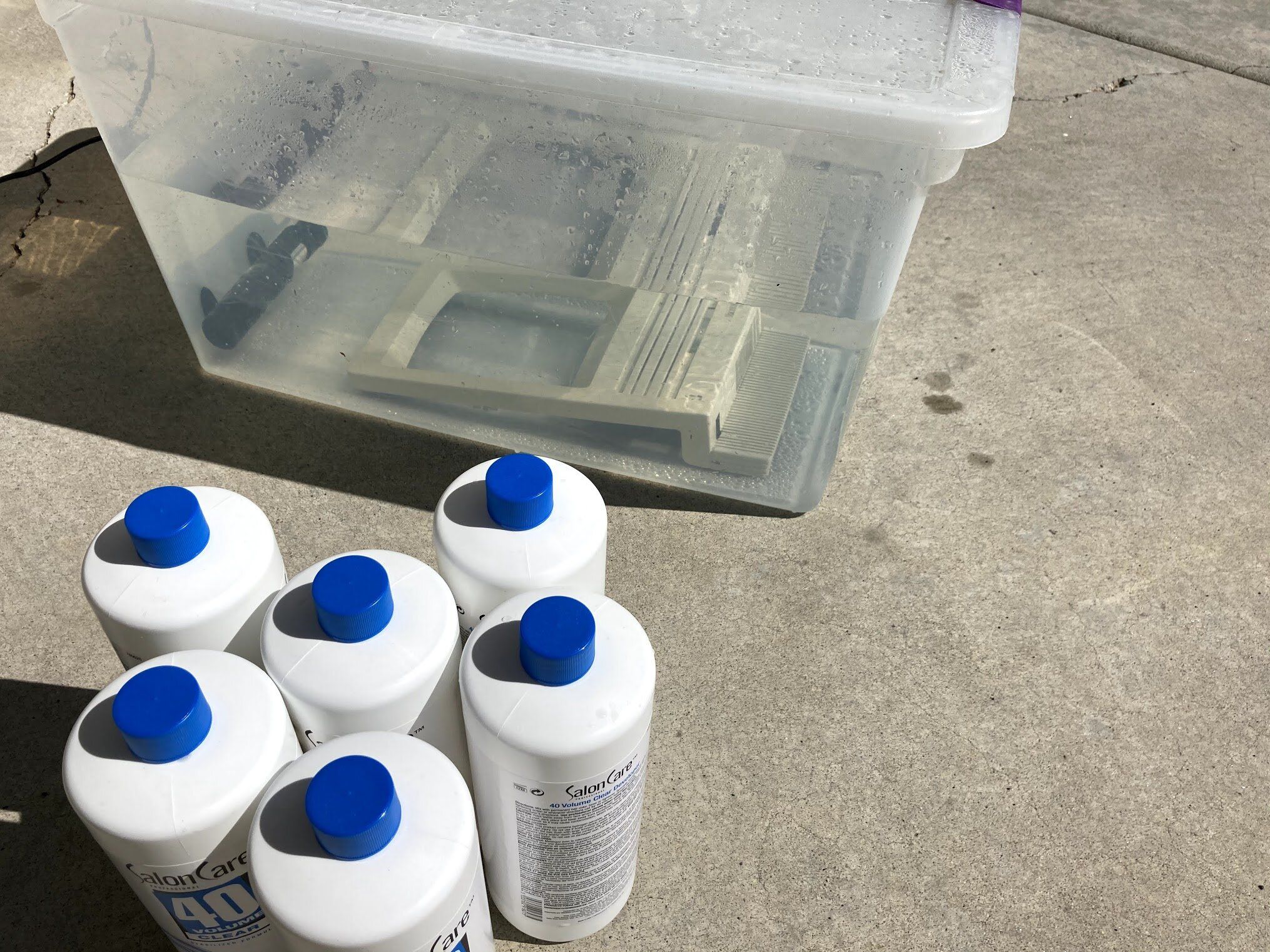

To prepare, I left some water out in my clear Sterilite container overnight. In the morning at 9 or 10 AM, it was about 24°C (75°F). We want about 35°C (95°F), which is where the reaction starts to happen.

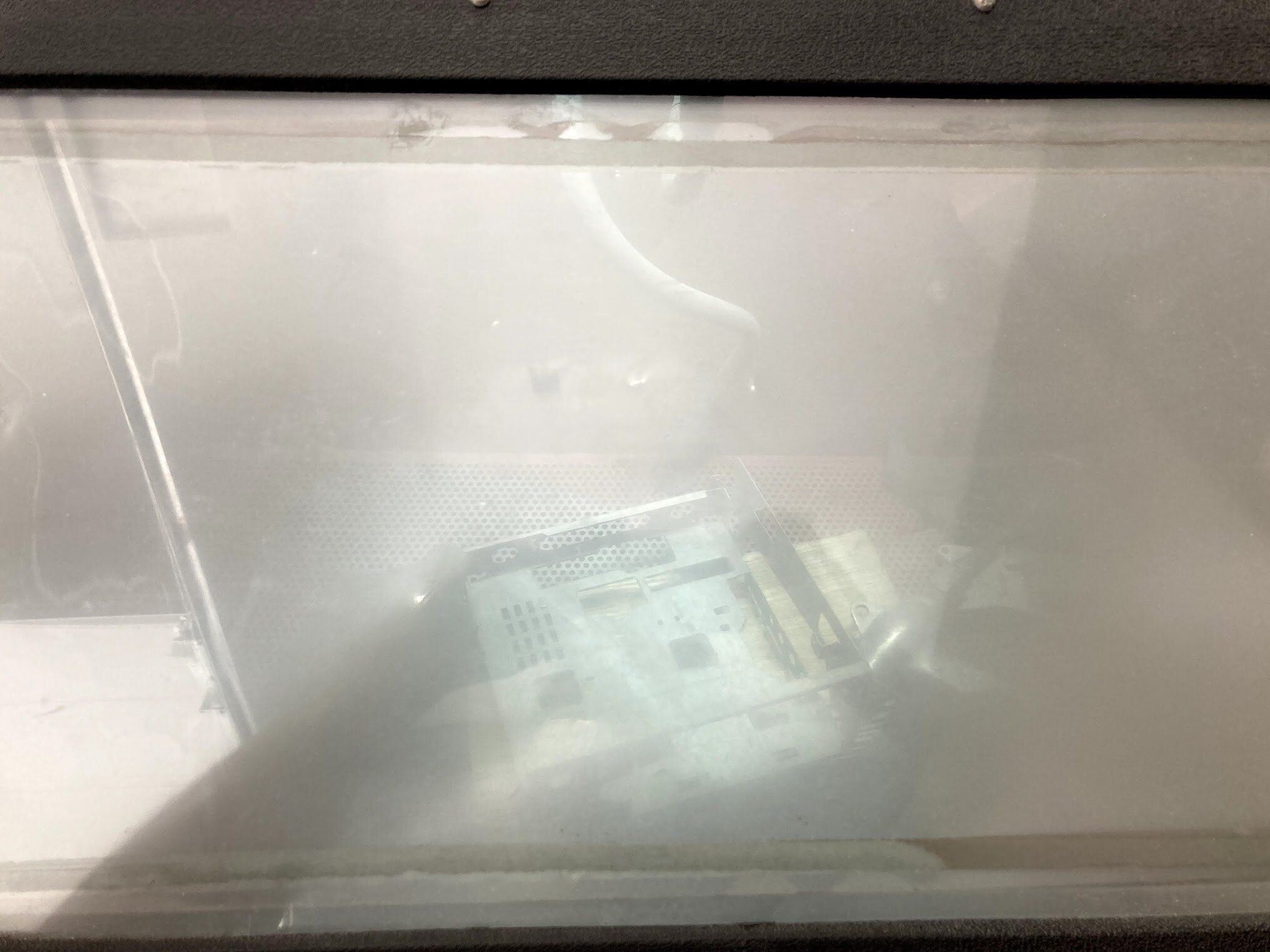

I dumped in about 6 bottles of 40-proof Hydrogen Peroxide. Normally, a couple would be fine, but the weather wasn't co-operating; it didn't look like it was going to be a very hot day. To help the problem, I added my $10 fish tank heater, which has a maximum temperature setting of about 35°C (95°F). The heater barely gets it hot enough for things to start happening, but it does help get the water up to temperature for the sun to take over and keep going.

Sadly, it just didn't end up getting very hot - the fish tank heater did the majority of the work, but it did seem to be working!

After about 4 hours, I swapped in the back, and left it in for the rest of the day.

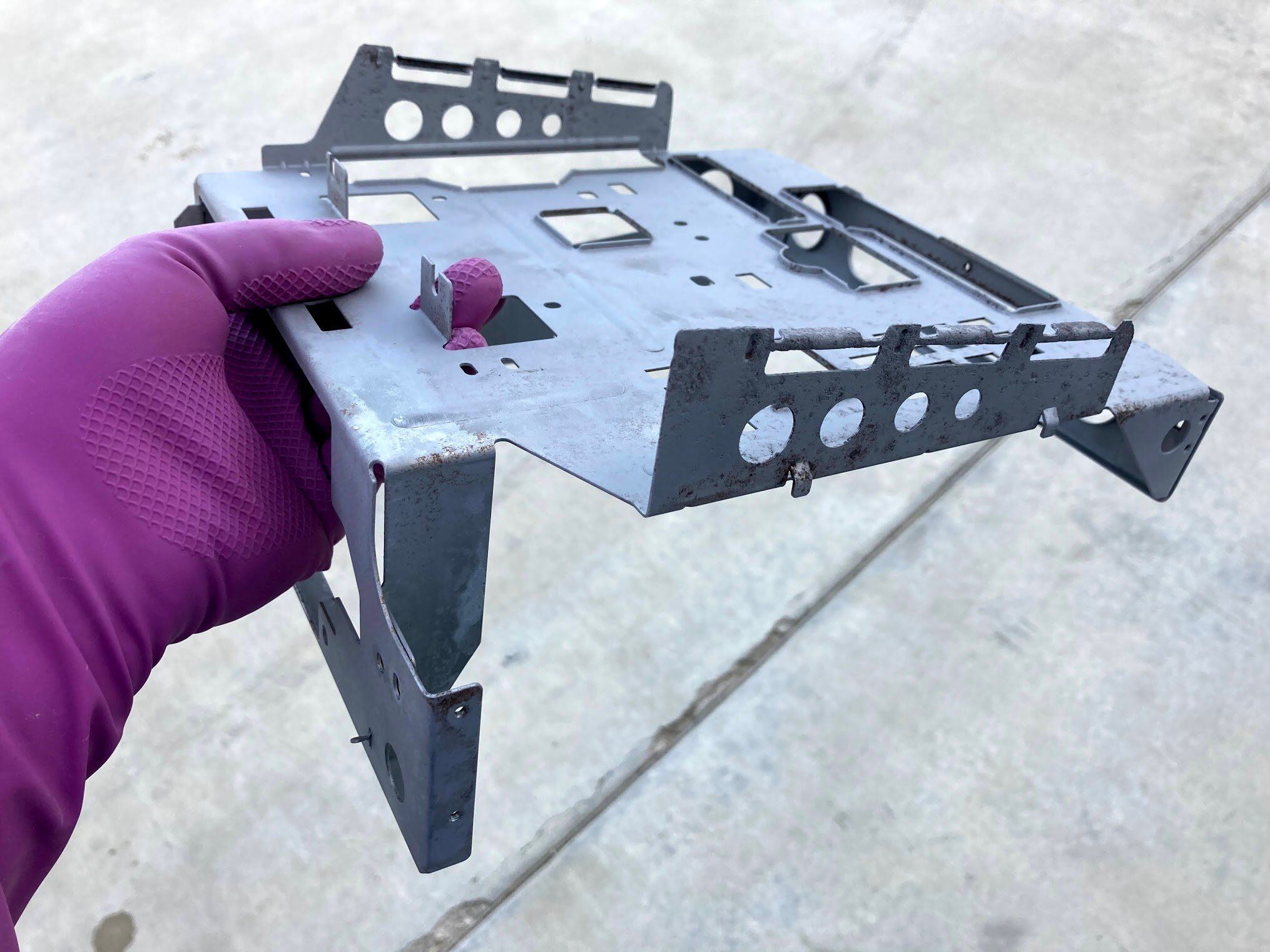

Towards the end of the day, I took the rusty chassis and logic board shield over to my brother's shop. He has a ton of great tools, like a sandblasting cabinet. I've never used one of these, and found that it's pretty hard to see what you're doing in the cabinet.

Here are the results. He instructed me to not touch the parts - just go home, hit them with compressed air, and apply primer.

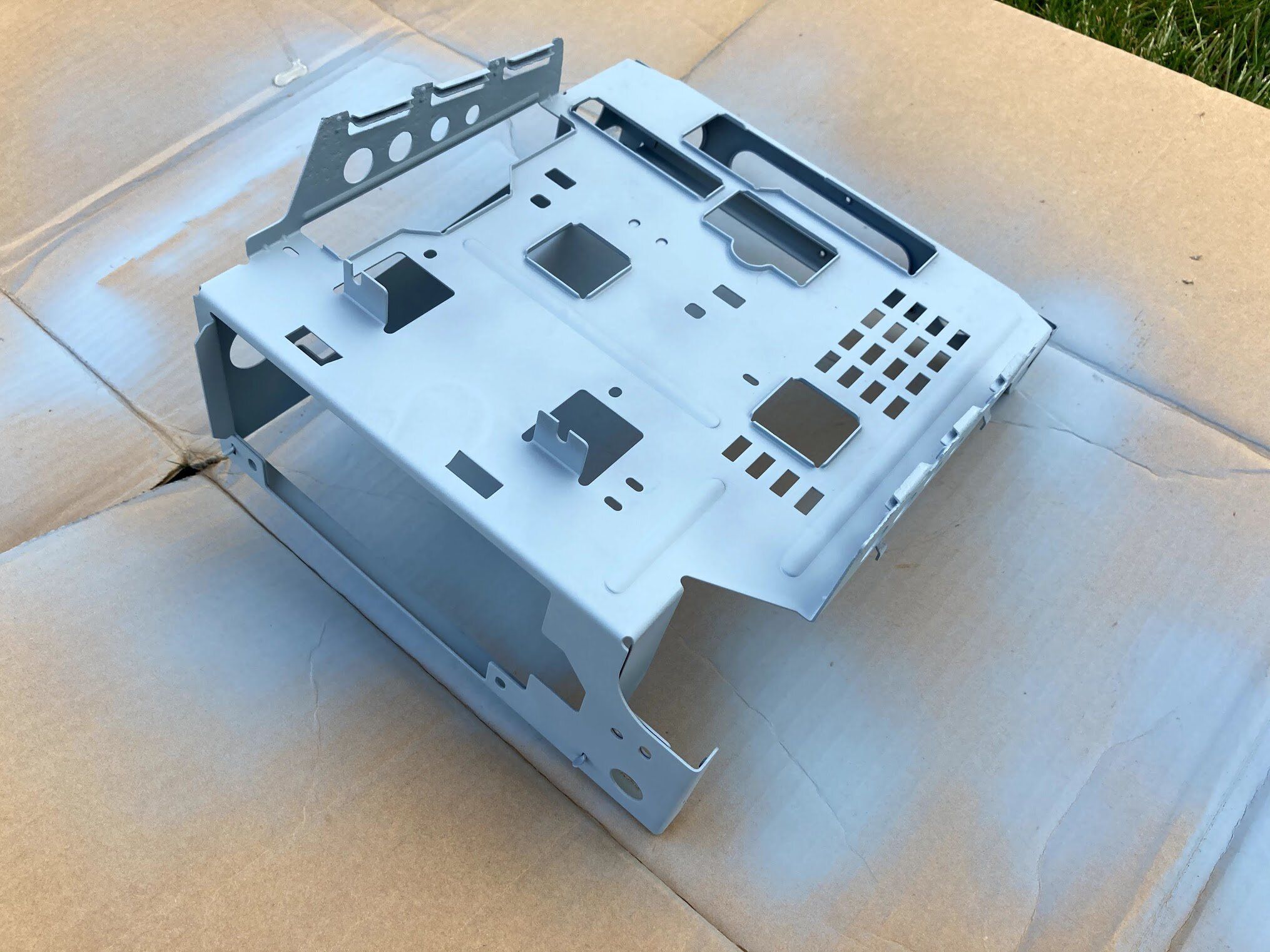

Keeping grounding in mind, I masked off a few things with tape, and hit the parts with some leftover engine primer that my brother gave me.

After a full day of retrobrite, even in the cooler weather, the parts were done. I think the high concentration of Hydrogen Peroxide, and the consistent 95°F from the fish tank heater did the job. Sadly, I didn't snap a photo at this stage, so the satisfying reveal will have to wait for the next post. Stay tuned!

To prepare, I left some water out in my clear Sterilite container overnight. In the morning at 9 or 10 AM, it was about 24°C (75°F). We want about 35°C (95°F), which is where the reaction starts to happen.

I dumped in about 6 bottles of 40-proof Hydrogen Peroxide. Normally, a couple would be fine, but the weather wasn't co-operating; it didn't look like it was going to be a very hot day. To help the problem, I added my $10 fish tank heater, which has a maximum temperature setting of about 35°C (95°F). The heater barely gets it hot enough for things to start happening, but it does help get the water up to temperature for the sun to take over and keep going.

Sadly, it just didn't end up getting very hot - the fish tank heater did the majority of the work, but it did seem to be working!

After about 4 hours, I swapped in the back, and left it in for the rest of the day.

Towards the end of the day, I took the rusty chassis and logic board shield over to my brother's shop. He has a ton of great tools, like a sandblasting cabinet. I've never used one of these, and found that it's pretty hard to see what you're doing in the cabinet.

Here are the results. He instructed me to not touch the parts - just go home, hit them with compressed air, and apply primer.

Keeping grounding in mind, I masked off a few things with tape, and hit the parts with some leftover engine primer that my brother gave me.

After a full day of retrobrite, even in the cooler weather, the parts were done. I think the high concentration of Hydrogen Peroxide, and the consistent 95°F from the fish tank heater did the job. Sadly, I didn't snap a photo at this stage, so the satisfying reveal will have to wait for the next post. Stay tuned!

Last edited:

I always get consistently good results from Retrobriting this way - I just wish i had some spare Apple badges!

Also for the chassis and metal parts - i found leaving them in my ultrasonic bath at 70*c for an hour, then hitting them with a 15 minute full sweep of ultrasonic cleaning made it look almost like new. No horrible rust anywhere!

Also for the chassis and metal parts - i found leaving them in my ultrasonic bath at 70*c for an hour, then hitting them with a 15 minute full sweep of ultrasonic cleaning made it look almost like new. No horrible rust anywhere!

Don't you guys with the heavy water damaged classics, think about to do some repaint, or colour cover on the metal structure?

I am continously thinking how cool would it be to have some fancy modern colour or exactly the oposite, some mated dark gray or black...

I am continously thinking how cool would it be to have some fancy modern colour or exactly the oposite, some mated dark gray or black...

I always get consistently good results from Retrobriting this way - I just wish i had some spare Apple badges!

Also for the chassis and metal parts - i found leaving them in my ultrasonic bath at 70*c for an hour, then hitting them with a 15 minute full sweep of ultrasonic cleaning made it look almost like new. No horrible rust anywhere!

Same and same on the retrobrite and spare Apple badges! This machine in particular could use a new badge. Ultrasonic cleaners look super cool - I'd love to have one someday.

Don't you guys with the heavy water damaged classics, think about to do some repaint, or colour cover on the metal structure?

Stay tuned.

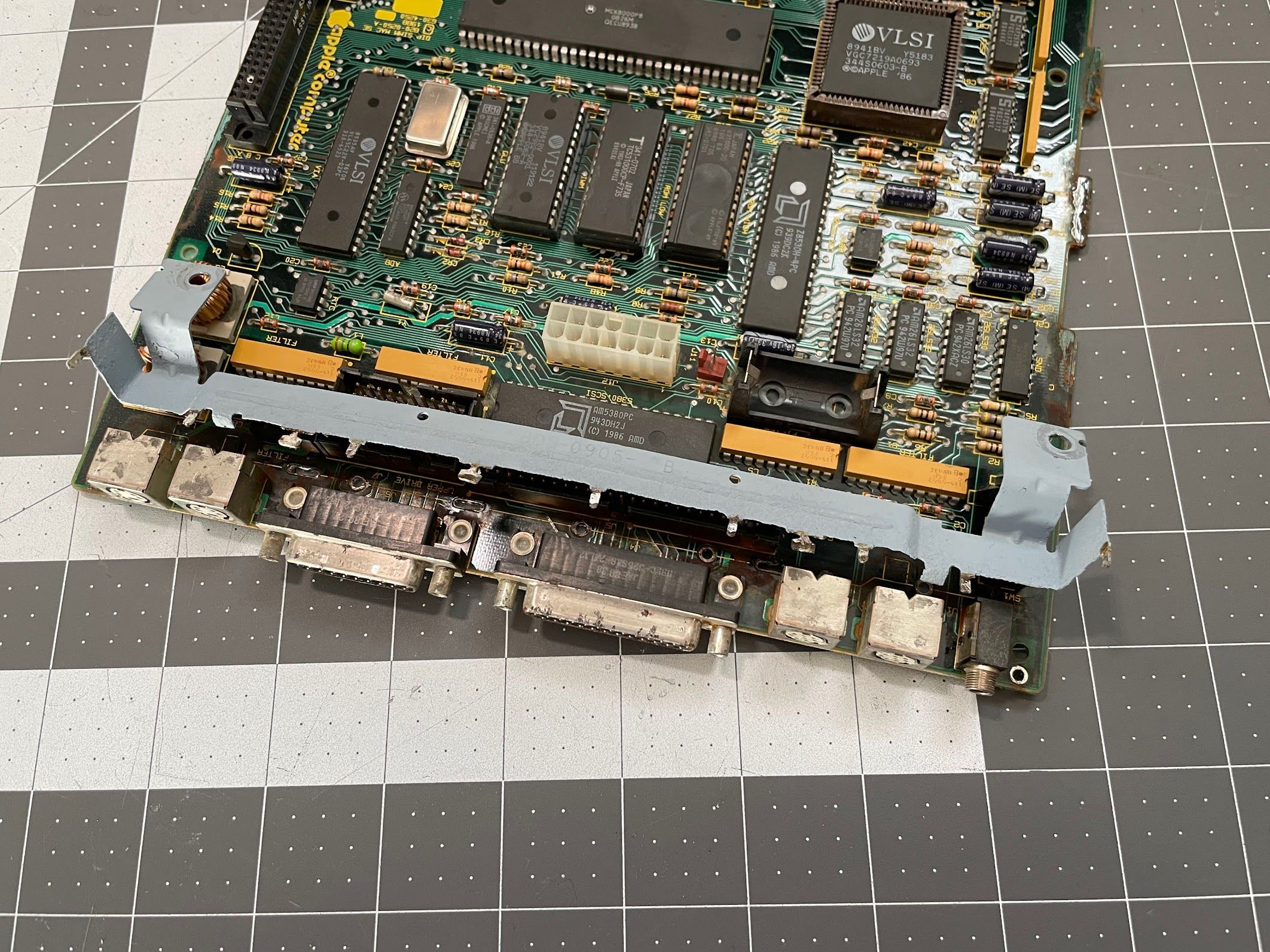

Before soldering the shield back onto the logic board, I decided to clean up the I/O ports a little bit. Here's what they looked like before.

And here's after working on them with some 1000-grit sandpaper. Much better!

After slotting in the RF shield, I bent the tabs like they were before. It was pretty easy to solder the shield in since it was held in place.

Shield installed!

Last edited:

Did you use conductive paint for the frame? If not, what’s your plan To ground it?

I just used some automotive primer, and I masked off key areas to ensure proper grounding between all of the parts. More on this later.

Next, it was time to recap the analog board. I don't always immediately jump to recapping the SE or SE/30 analog boards, but considering the mess that this machine was when I got it, I figure it could use all of the help it can get. Besides, maybe some fresh caps will help that dim CRT out?

Normally, I like to provide an exact capacitor list in these build threads. Unfortunately, I did this recap (and all of the restoration that you've read about so far) in the Spring of 2020 - right when COVID was hitting everything, and supply chains were a mess.

Because of that, I wasn't able to replace every cap. Additionally, several of the caps that I used are now out of stock, or have become obsolete. In light of this, I've updated my list of Macintosh SE Analog board capacitors, but you'll want to double-check my work and make sure it is complete. I know at least one cap (a non-polar one) is not on the list. Anyway, here's a link to add my capacitor kit to your shopping cart on DigiKey.

Now, let's get to the recap of the... uh... recap.

First, I marked the old caps with a green Sharpie to keep track of what I'd replaced.

Then, one at a time, I desoldered caps. Sometimes I heat one leg and rock the cap, sometimes I used the soldering sucker, and sometimes desoldering braid.

New cap installed here! I always solder one leg, and apply gentle pressure from the back while reheating that leg, which seats the cap firmly against the board.

Here's a new cap, and an old cap that I couldn't get a replacement part for. I try to find the same diameter and leg spacing, but I don't worry about height. I also try to use Nichicon or Panasonic for electrolytic caps.

With that, the analog board is recapped!

Last edited:

At last, time to reassemble! Good thing too... at the time, my office had two torn-apart SE's, a torn-apart SE/30, and torn-apart external floppy drive! First, I hot glued the speaker back in. I find this method to be passable at best... sometimes, the speaker pops back out. I feel like epoxy would be a bit much, so I've just been using hot glue until I discover something better.

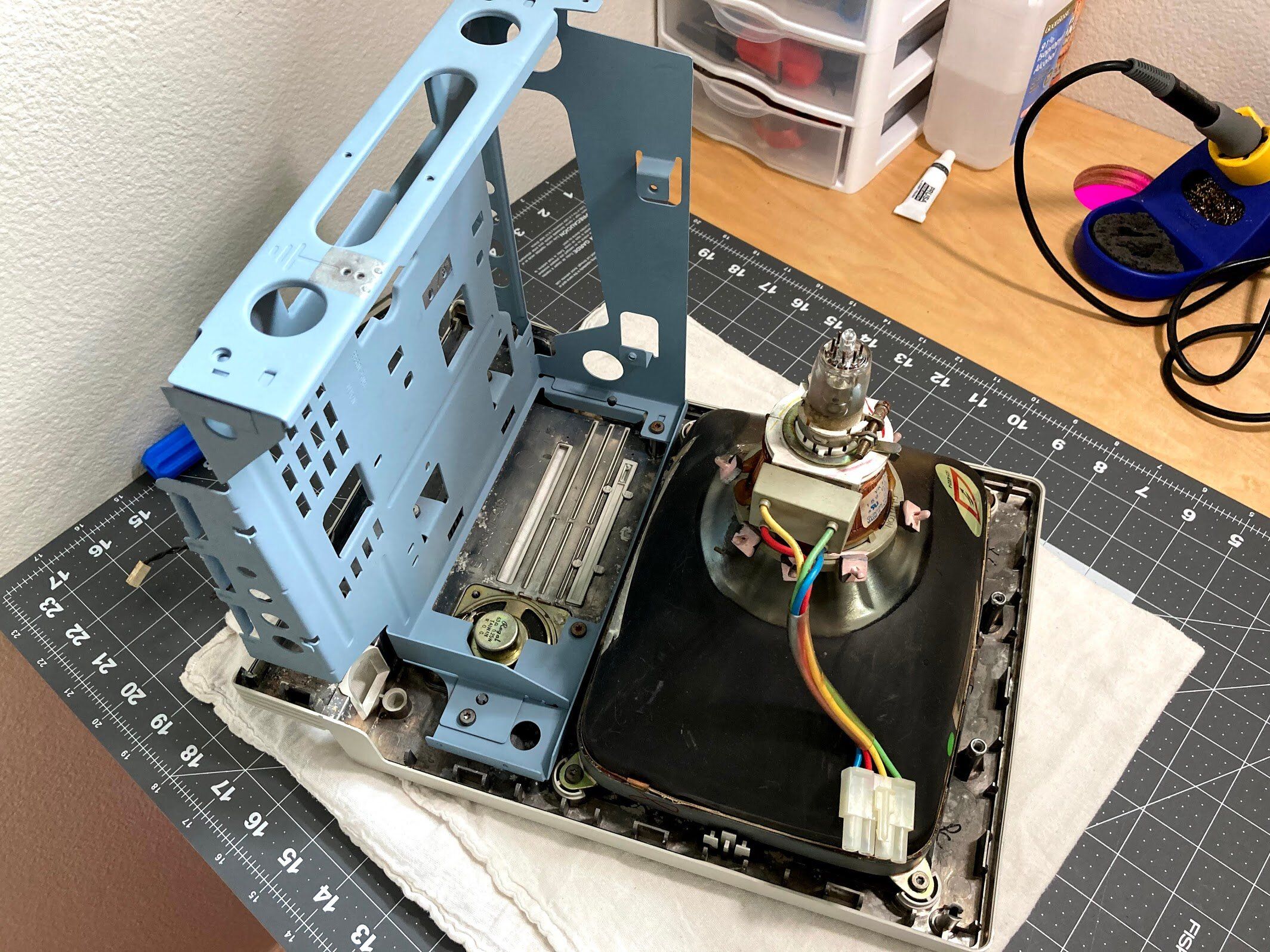

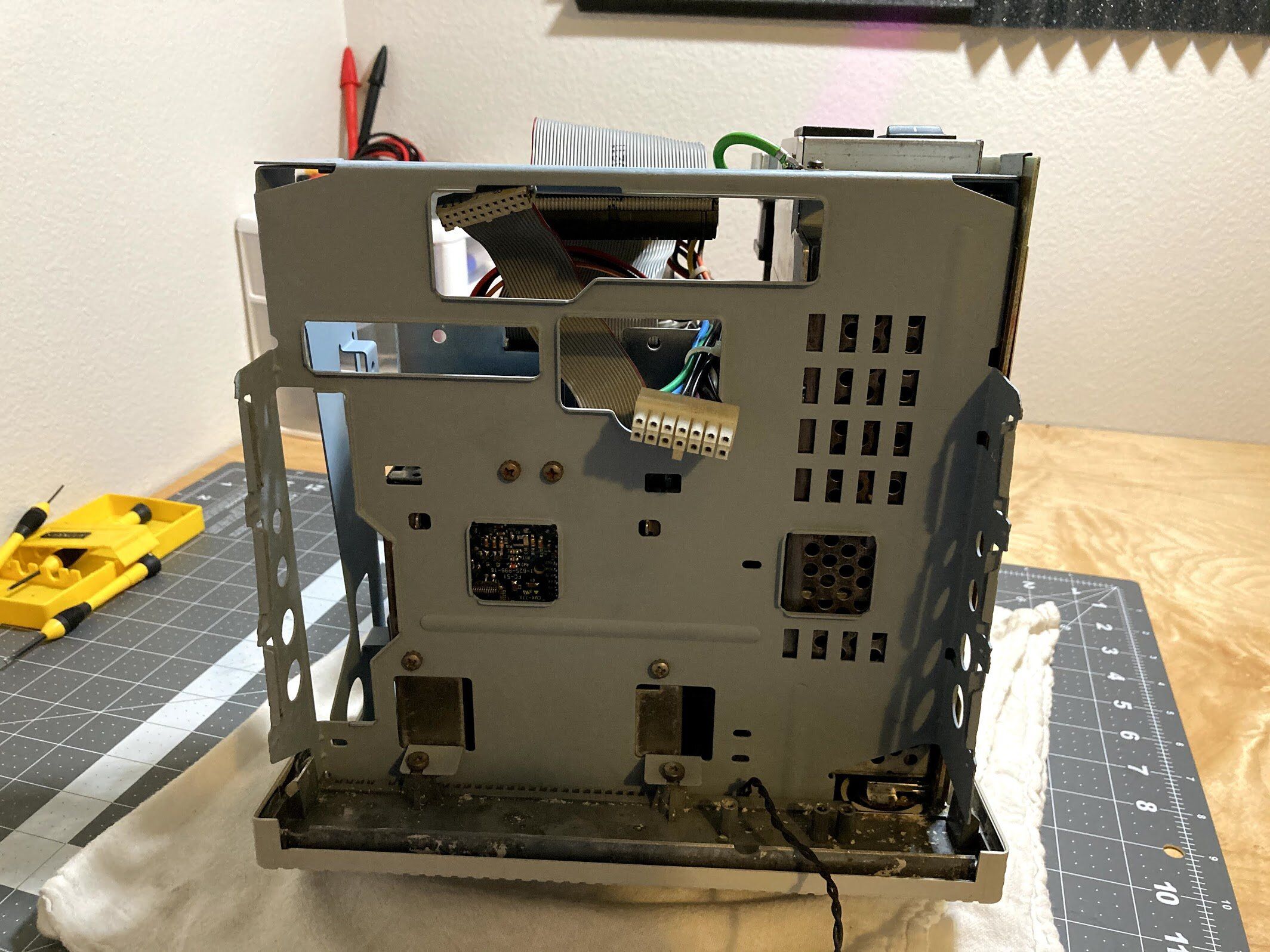

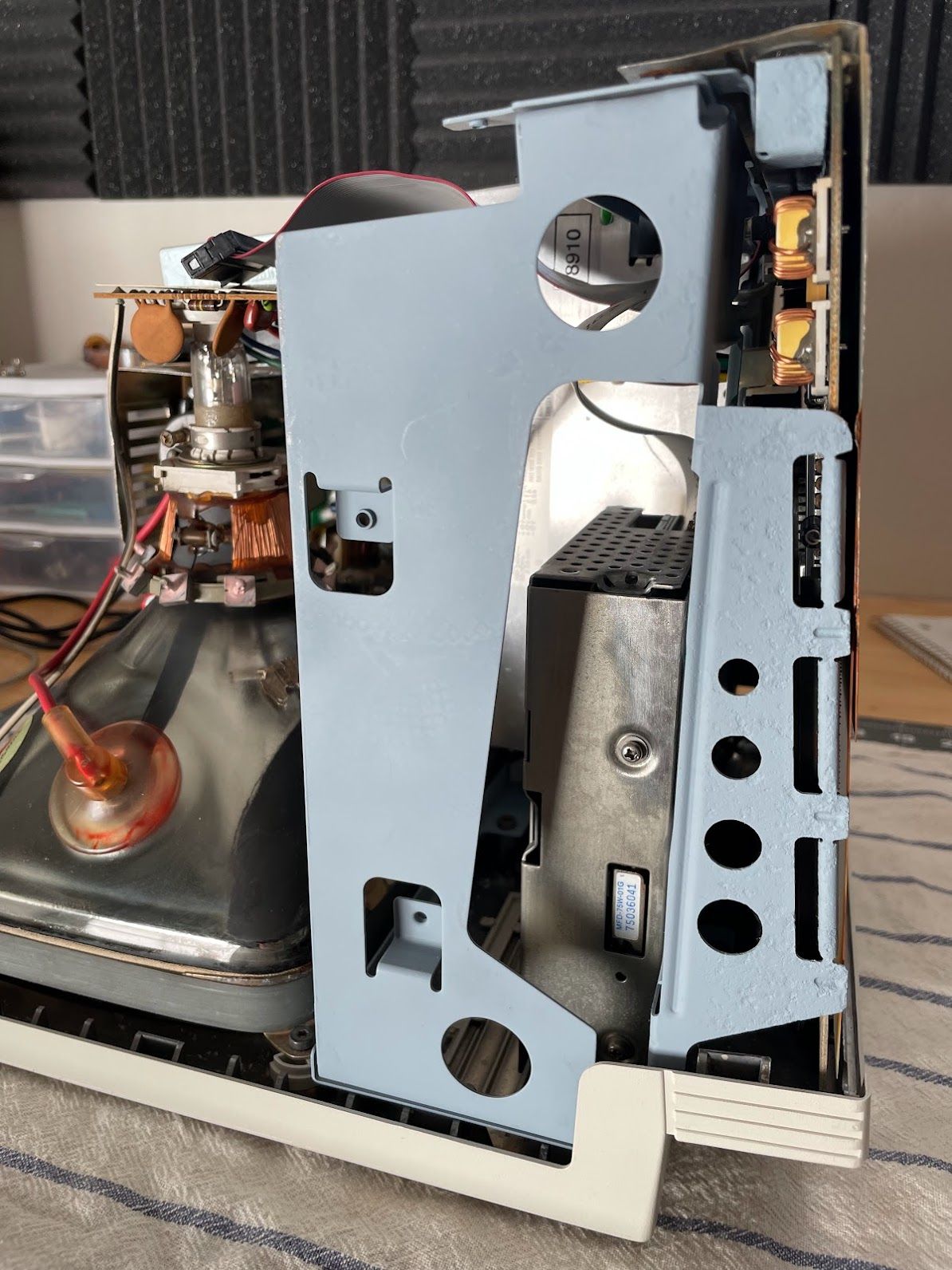

Next, I reinstalled the chassis. Yikes, it is blue! But at this point, I had decided that there was no need to spend money on grey or silver paint. I just wanted to stop the rust. I have plenty of Macs that I make "perfect". Most people would have just thrown this one out anyway, I've already put too much effort into it. Right?

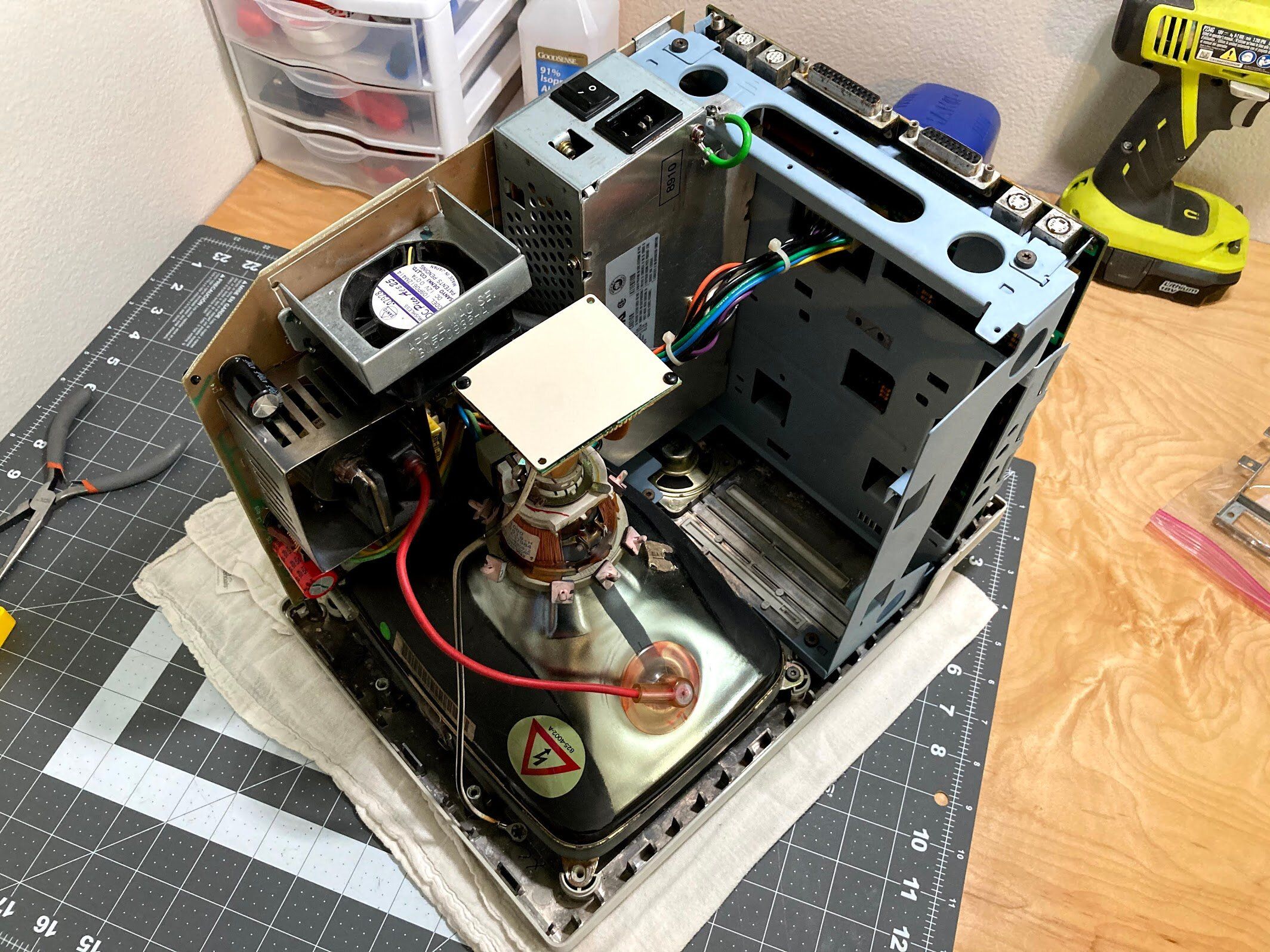

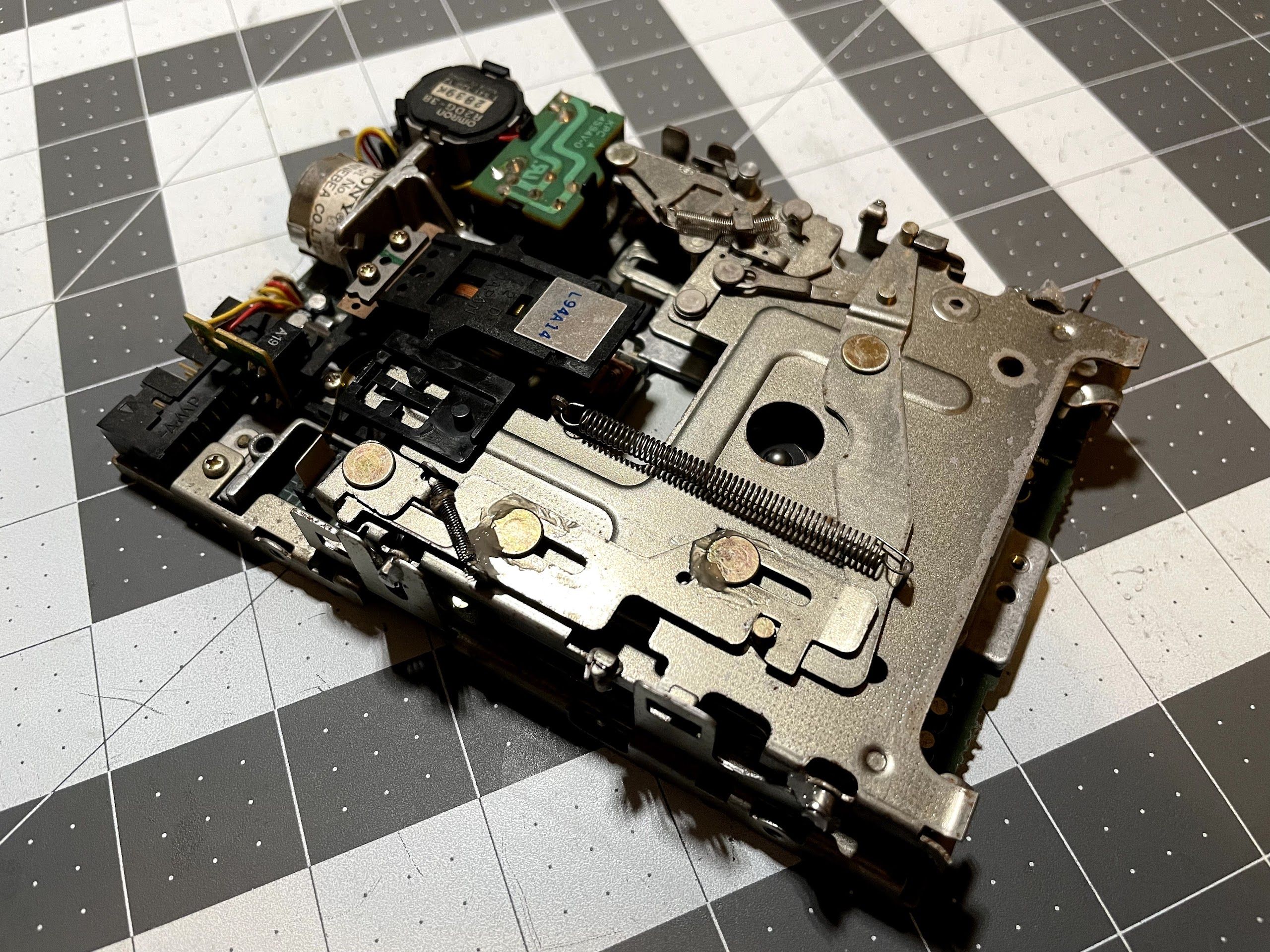

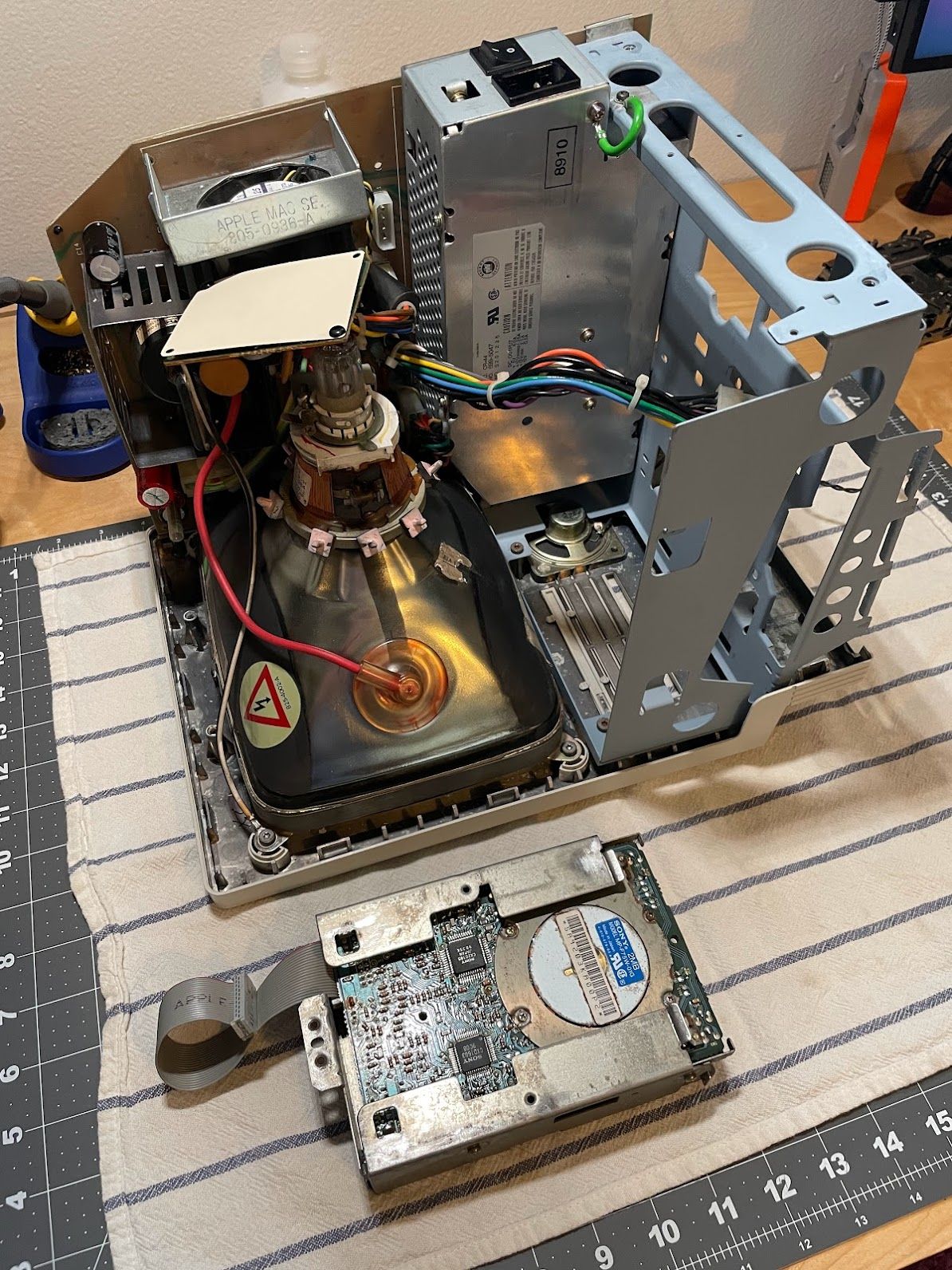

Jumping ahead a bit, I installed the analog board and logic board, but left the floppy drive and hard drive out to do a quick power-on test.

The ground lug on the CRT was a bit rusty, so I cleaned it up with some sandpaper to ensure a good connection here.

Time for the power-on test!

Yep, still works! One thing I hadn't tested before now was sound. No problem, it chimed as usual. The CRT is pretty far out of adjustment. I'll need to adjust rotation, width, height, and centering at some point.

Next up, the floppy drive.

Next, I reinstalled the chassis. Yikes, it is blue! But at this point, I had decided that there was no need to spend money on grey or silver paint. I just wanted to stop the rust. I have plenty of Macs that I make "perfect". Most people would have just thrown this one out anyway, I've already put too much effort into it. Right?

Jumping ahead a bit, I installed the analog board and logic board, but left the floppy drive and hard drive out to do a quick power-on test.

The ground lug on the CRT was a bit rusty, so I cleaned it up with some sandpaper to ensure a good connection here.

Time for the power-on test!

Yep, still works! One thing I hadn't tested before now was sound. No problem, it chimed as usual. The CRT is pretty far out of adjustment. I'll need to adjust rotation, width, height, and centering at some point.

Next up, the floppy drive.

Last edited:

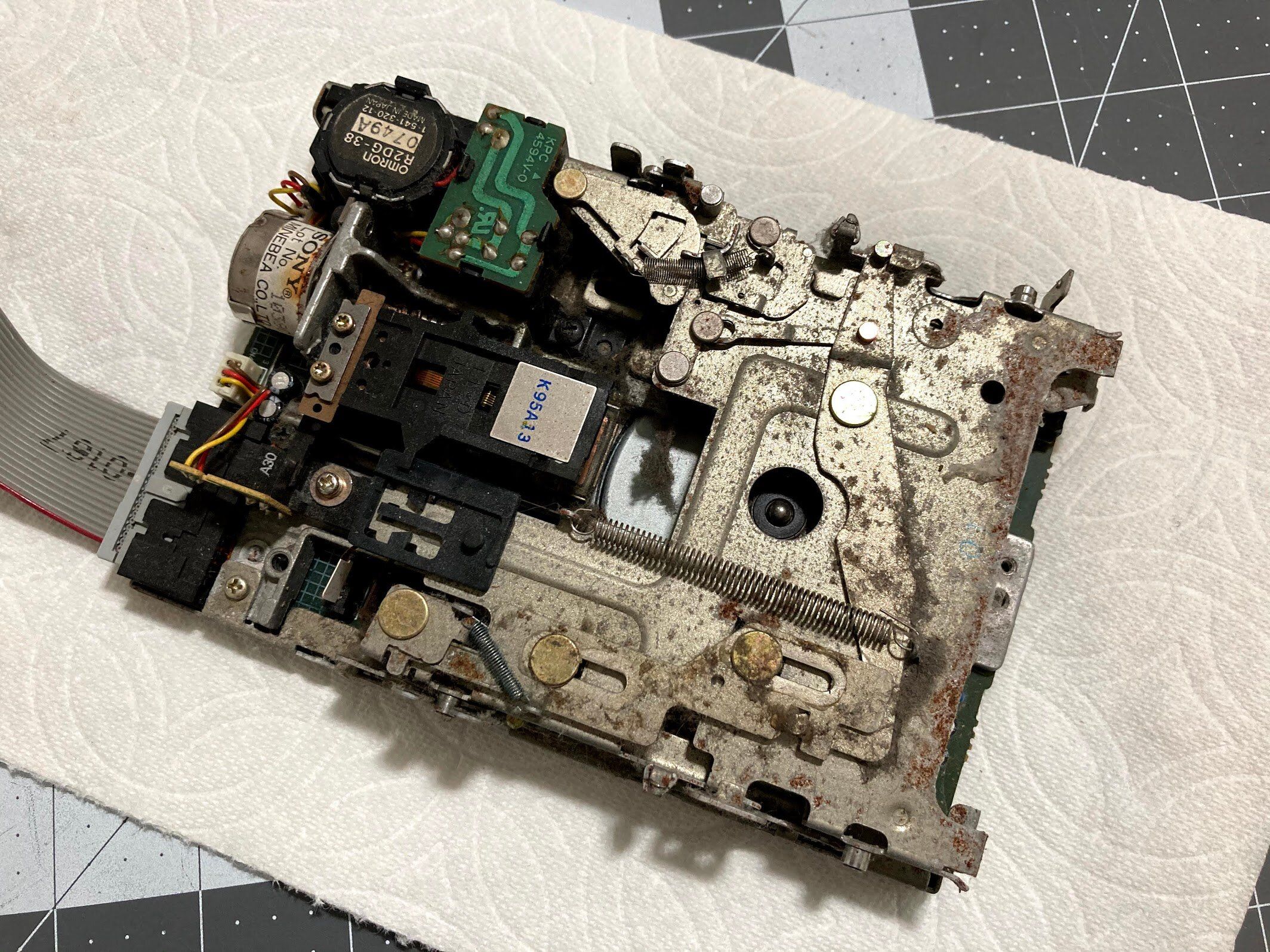

Next, it was time to service the floppy drive. Before tearing into it, I had pretty high hopes for it. Up until this point, I'd been able to resurrect every drive I'd come across.

I'm not going to waste your time (or TinkerDifferent's bandwidth) on this one though... we'll stick to the quick version of the story. After soaking rusted parts in vinegar, thoroughly cleaning everything, and lubricating all of the moving parts, I reinstalled the floppy drive and hard drive.

At this point, both the hard drive and floppy drive were completely untested. It was finally time for the big moment where I would see if the floppy drive worked, and if the hard drive worked, and if there was anything interesting on it!

I flipped on the power, and immediately, very bad things started happening. The machine rapidly went "FLUP FLUP FLUP FLUP FLUP", and by the time I got my hand back around to the power switch, there was a big puff of magic smoke coming from the hard drive and floppy drive area! Oh no!

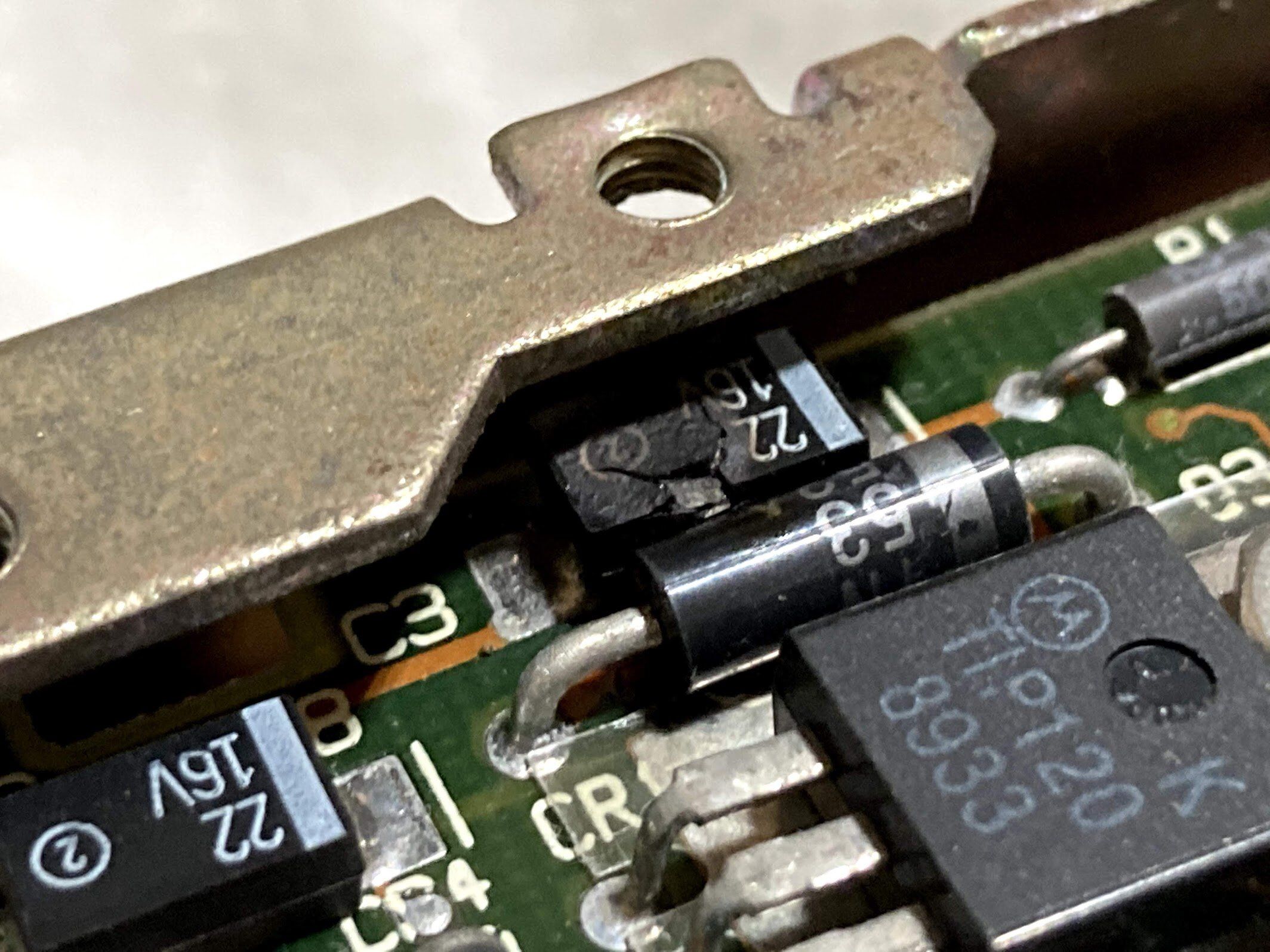

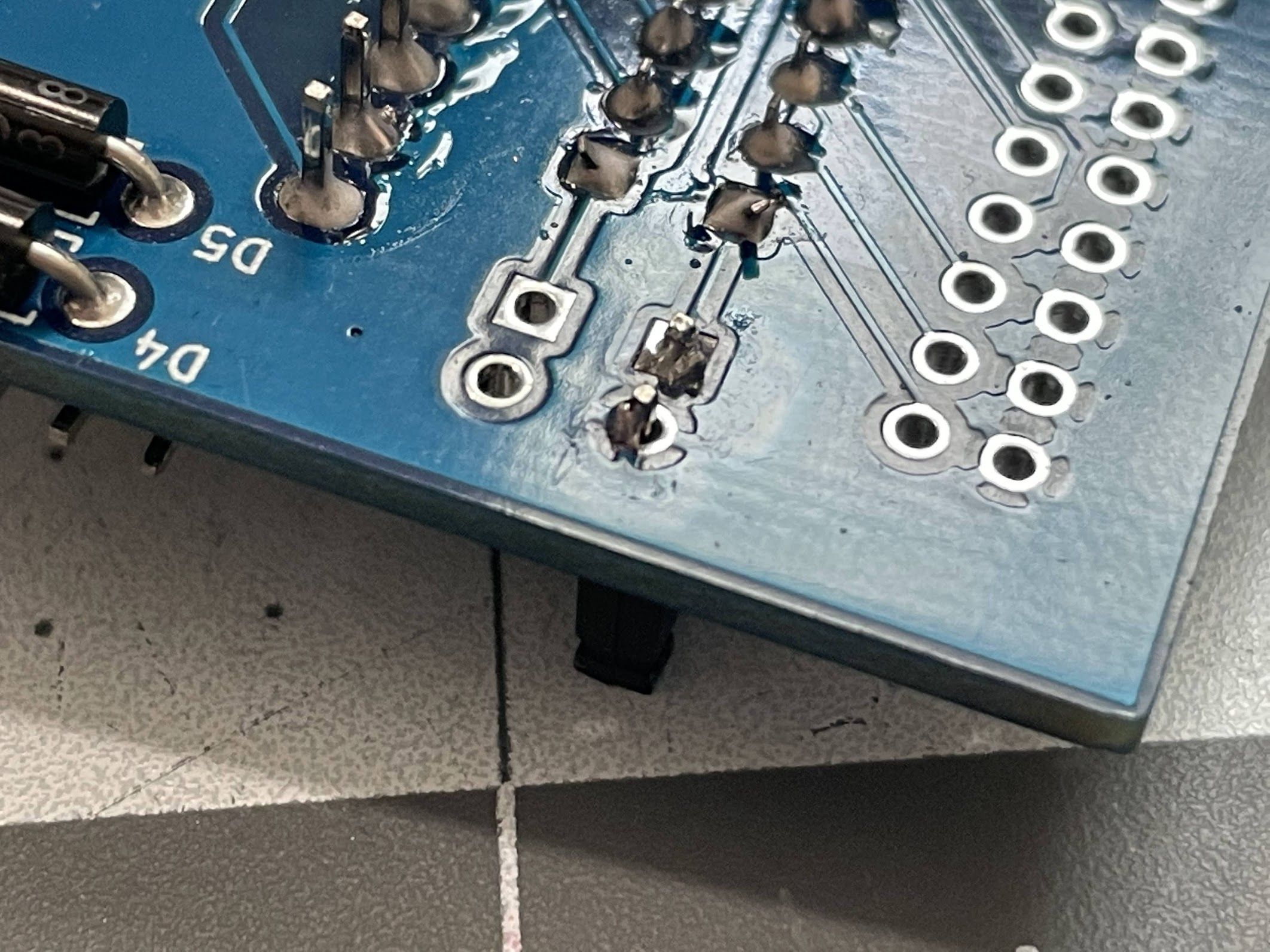

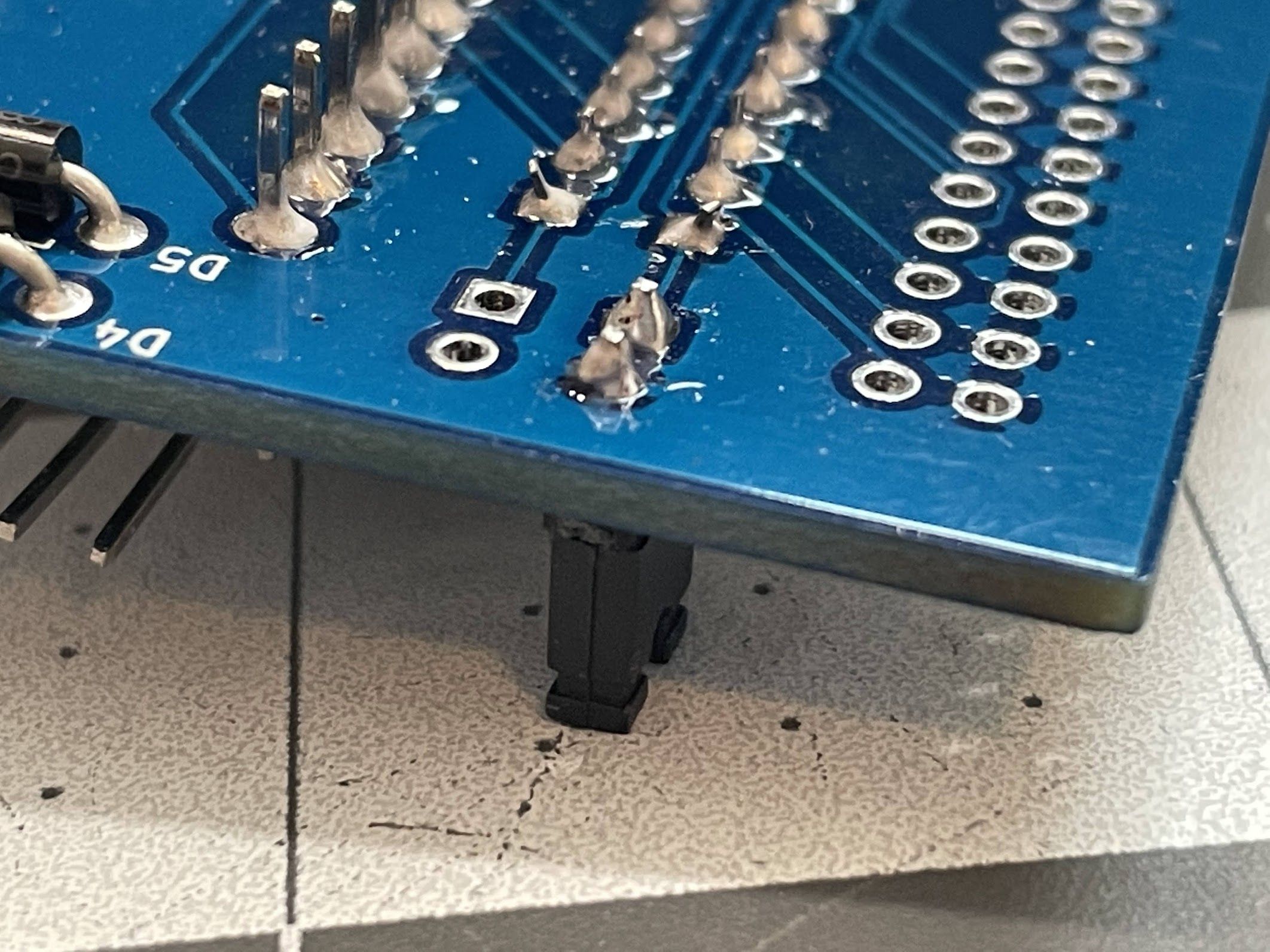

With the power back off, I waved all of the smoke away and took things back apart to find out what burned up. And burn up, something did! My office smelled horrible! I was really hoping that whatever had failed was the hard drive, and not the floppy drive or logic board. The logic board checked out okay, but I quickly discovered this on the hard drive:

Looks like a Tantalum capacitor gave up! If I had to guess, I'd say that the spindle or stepper motor was stuck, and it overwhelmed the circuitry. Oh noooooooo, a MiniScribe died! Oh well, I need a hard drive bracket for my SE/30. I guess this is where I'm getting it. Bye-bye hard drive!

I was a bit worried that the hard drive might have damaged the machine, but that didn't seem to be the case - it powered on and chimed just fine, sans hard drive.

So, how about that floppy drive? Sadly, no luck here either. On power-on, something in the drive just buzzed and buzzed. I tore it back apart to find that the r/w head actuator motor was full of rust. Since it's a sealed unit, there's no possibility of repairing it. I'd have to either get a replacement motor, or replacement SuperDrive.

I'm not going to waste your time (or TinkerDifferent's bandwidth) on this one though... we'll stick to the quick version of the story. After soaking rusted parts in vinegar, thoroughly cleaning everything, and lubricating all of the moving parts, I reinstalled the floppy drive and hard drive.

At this point, both the hard drive and floppy drive were completely untested. It was finally time for the big moment where I would see if the floppy drive worked, and if the hard drive worked, and if there was anything interesting on it!

I flipped on the power, and immediately, very bad things started happening. The machine rapidly went "FLUP FLUP FLUP FLUP FLUP", and by the time I got my hand back around to the power switch, there was a big puff of magic smoke coming from the hard drive and floppy drive area! Oh no!

With the power back off, I waved all of the smoke away and took things back apart to find out what burned up. And burn up, something did! My office smelled horrible! I was really hoping that whatever had failed was the hard drive, and not the floppy drive or logic board. The logic board checked out okay, but I quickly discovered this on the hard drive:

Looks like a Tantalum capacitor gave up! If I had to guess, I'd say that the spindle or stepper motor was stuck, and it overwhelmed the circuitry. Oh noooooooo, a MiniScribe died! Oh well, I need a hard drive bracket for my SE/30. I guess this is where I'm getting it. Bye-bye hard drive!

I was a bit worried that the hard drive might have damaged the machine, but that didn't seem to be the case - it powered on and chimed just fine, sans hard drive.

So, how about that floppy drive? Sadly, no luck here either. On power-on, something in the drive just buzzed and buzzed. I tore it back apart to find that the r/w head actuator motor was full of rust. Since it's a sealed unit, there's no possibility of repairing it. I'd have to either get a replacement motor, or replacement SuperDrive.

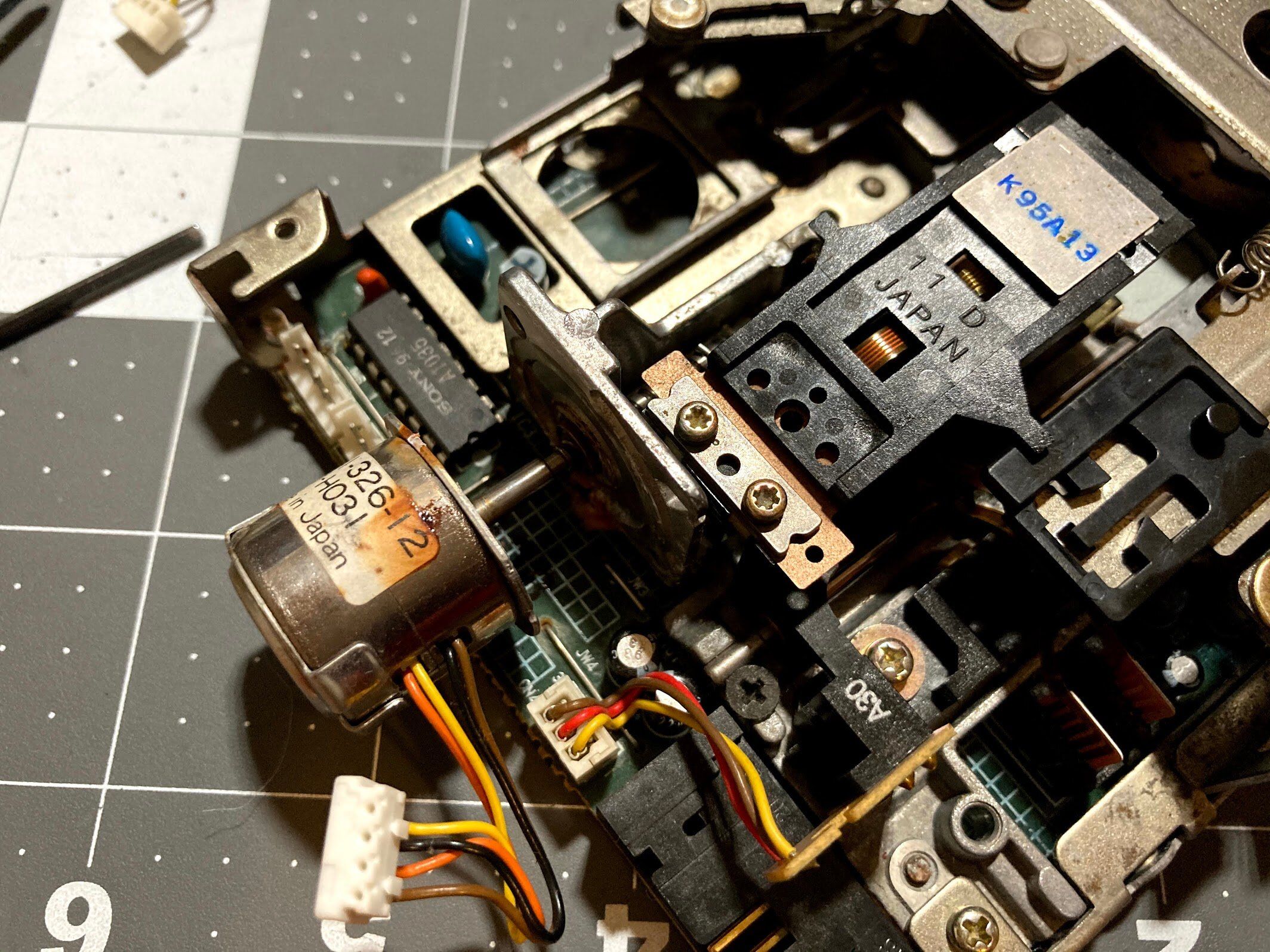

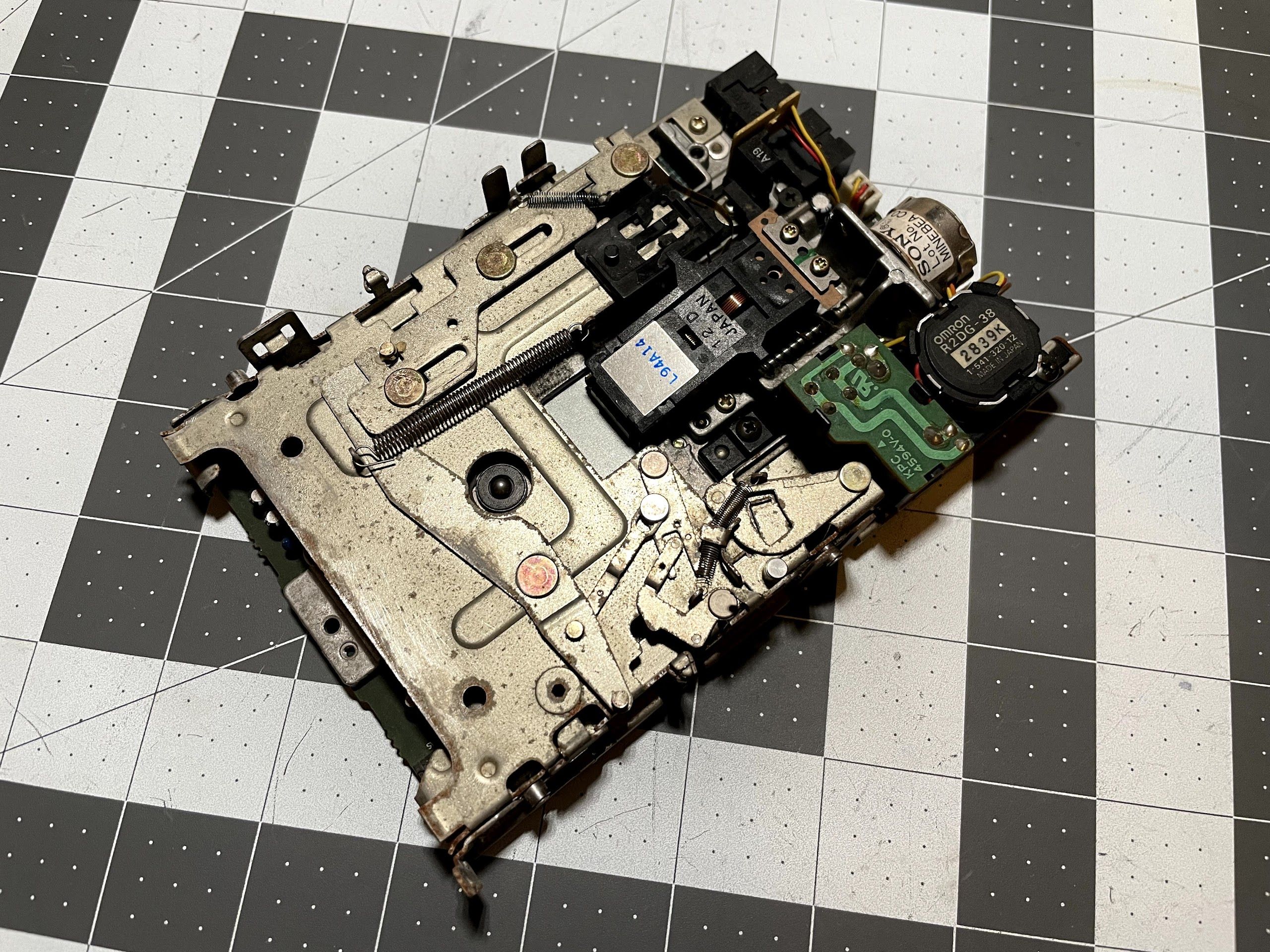

Fast forward from June, 2020 to May, 2021. During this time, @eric has sent me a donor SuperDrive for this Macintosh SE FDHD. I specifically asked for one that hadn't been serviced, so that we could go through the process here.

Here's the drive! It's a bit rusty too, but absolutely nothing like the drive that came in this machine. I think this will clean up nicely.

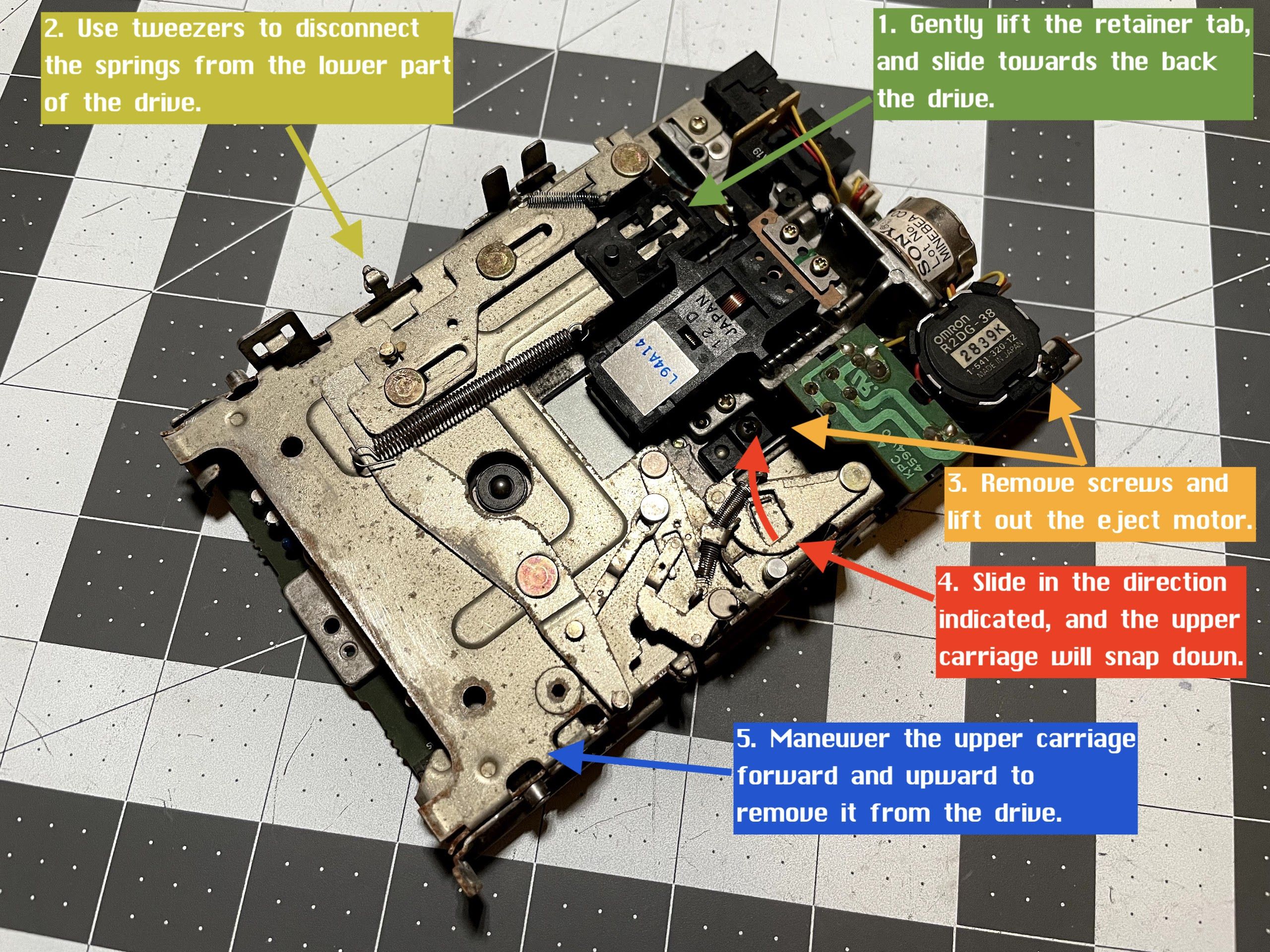

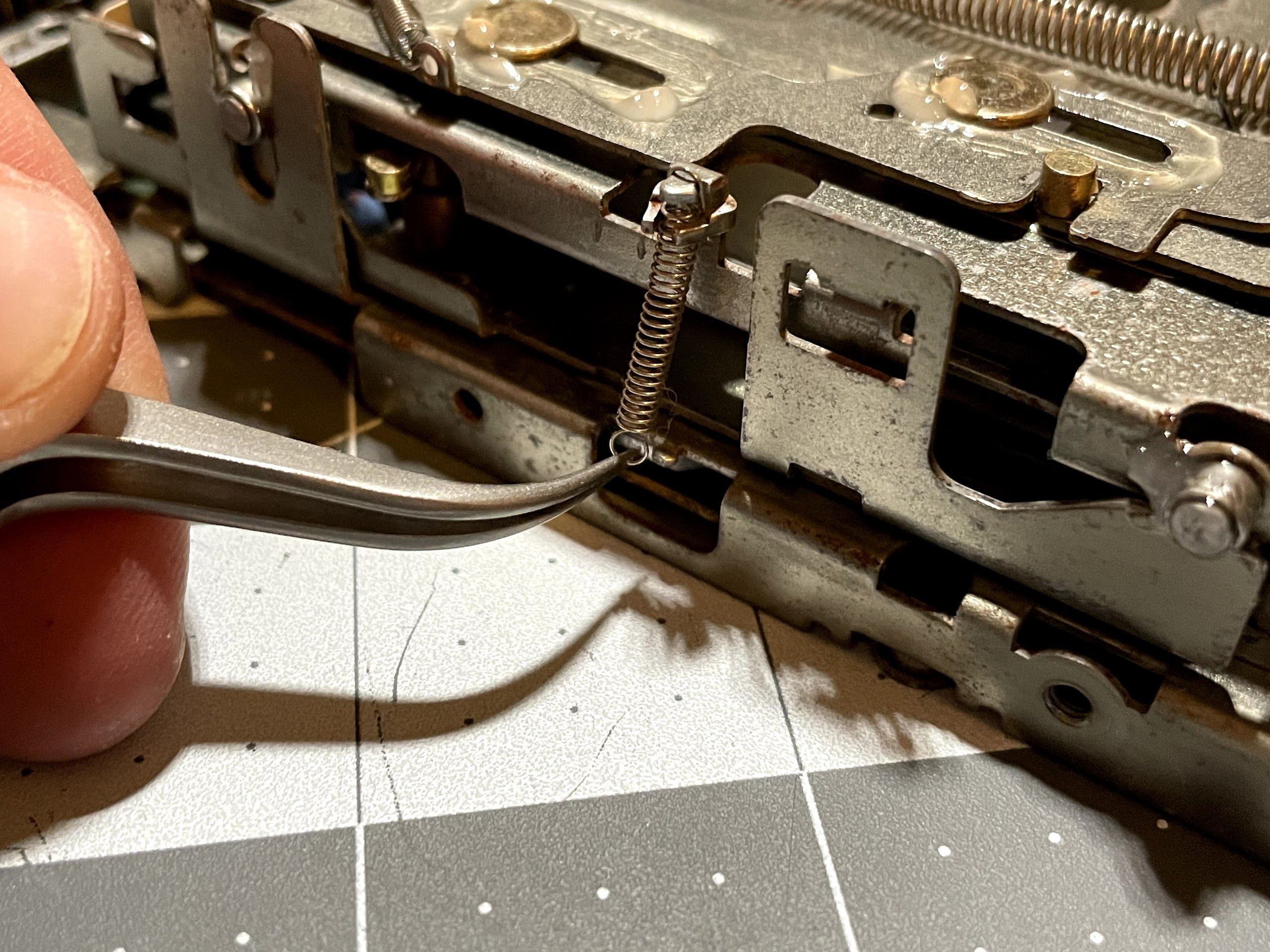

First, I used tweezers to disconnect the springs. They stay attached on the top.

Next, I removed the two screws that hold the eject motor into place. I recommend being careful with these - it's easy to strip the heads!

The next part of kinda hard to explain, so I made a quick diagram showing all of the steps. Step 4 is a bit tricky - I always forget exactly how to do it, but you'll know the instant you figure it out. The drive goes SNAP! Step 5 involves some maneuvering, but you can work the upper carriage out pretty easily.

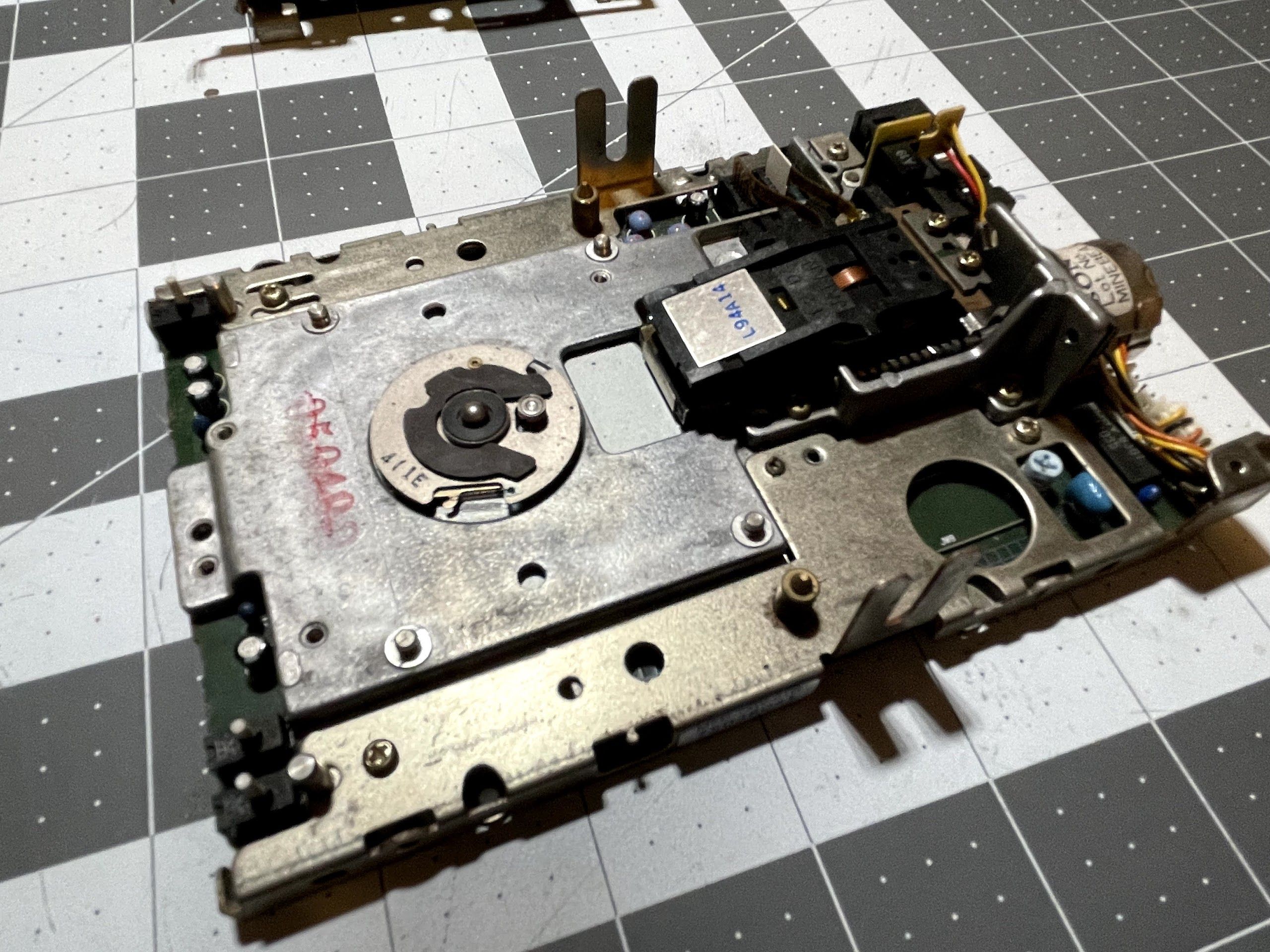

After removing the upper carriage, use pliers to remove the little snap-rings that hold the lower carriage to the drive.

With that, the drive was completely disassembled.

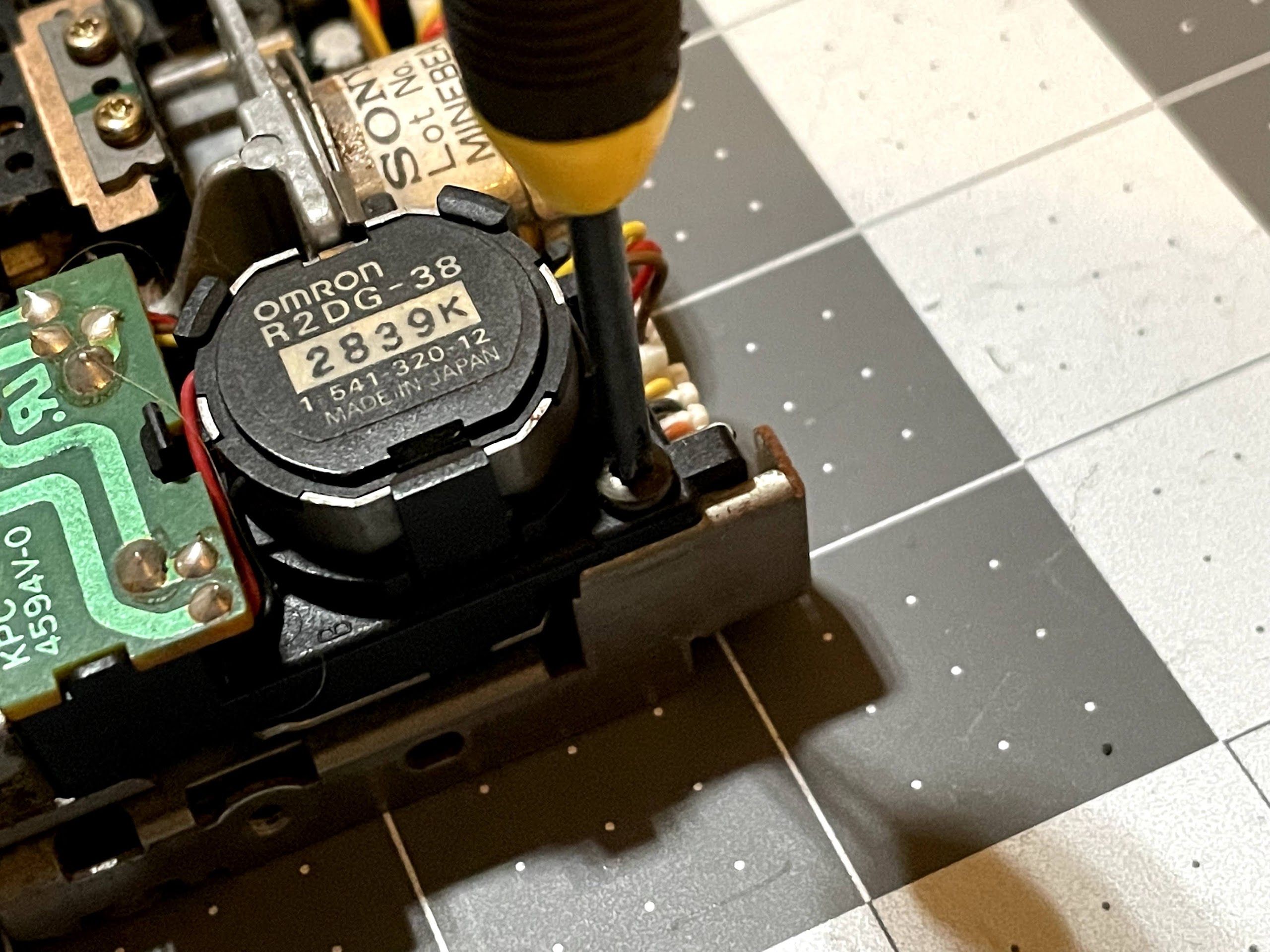

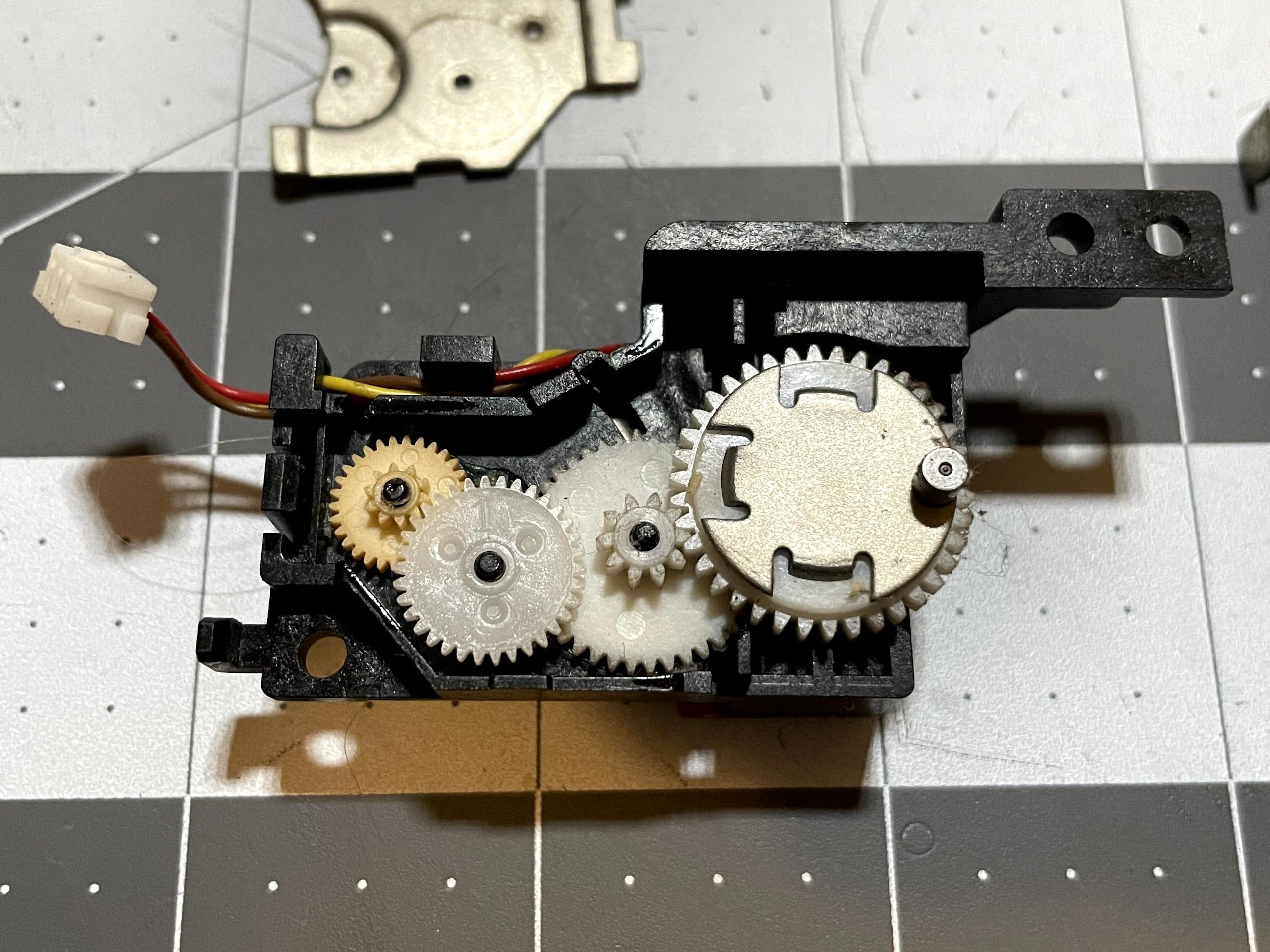

Next, I decided to clean up and lubricate the eject motor gears. I used a small screwdriver to pop the metal shield off, exposing the gears.

A couple of the gears can be removed easily with tweezers. The dark yellow one is know to break, but fortunately, there are 3D printed reproductions available. These prints are done on a different type of printer than my FDM (fused deposition modeling) printer that can hit much higher resolution. Fortunately, we don't need a replacement gear here yet. I always clean and lubricate these drives before using them to try to avoid snapping a gear.

I swabbed everything out with alcohol and cotton swabs, then added a couple of drops of Teflon Silicon lubricant.

Here's the drive! It's a bit rusty too, but absolutely nothing like the drive that came in this machine. I think this will clean up nicely.

First, I used tweezers to disconnect the springs. They stay attached on the top.

Next, I removed the two screws that hold the eject motor into place. I recommend being careful with these - it's easy to strip the heads!

The next part of kinda hard to explain, so I made a quick diagram showing all of the steps. Step 4 is a bit tricky - I always forget exactly how to do it, but you'll know the instant you figure it out. The drive goes SNAP! Step 5 involves some maneuvering, but you can work the upper carriage out pretty easily.

After removing the upper carriage, use pliers to remove the little snap-rings that hold the lower carriage to the drive.

With that, the drive was completely disassembled.

Next, I decided to clean up and lubricate the eject motor gears. I used a small screwdriver to pop the metal shield off, exposing the gears.

A couple of the gears can be removed easily with tweezers. The dark yellow one is know to break, but fortunately, there are 3D printed reproductions available. These prints are done on a different type of printer than my FDM (fused deposition modeling) printer that can hit much higher resolution. Fortunately, we don't need a replacement gear here yet. I always clean and lubricate these drives before using them to try to avoid snapping a gear.

I swabbed everything out with alcohol and cotton swabs, then added a couple of drops of Teflon Silicon lubricant.

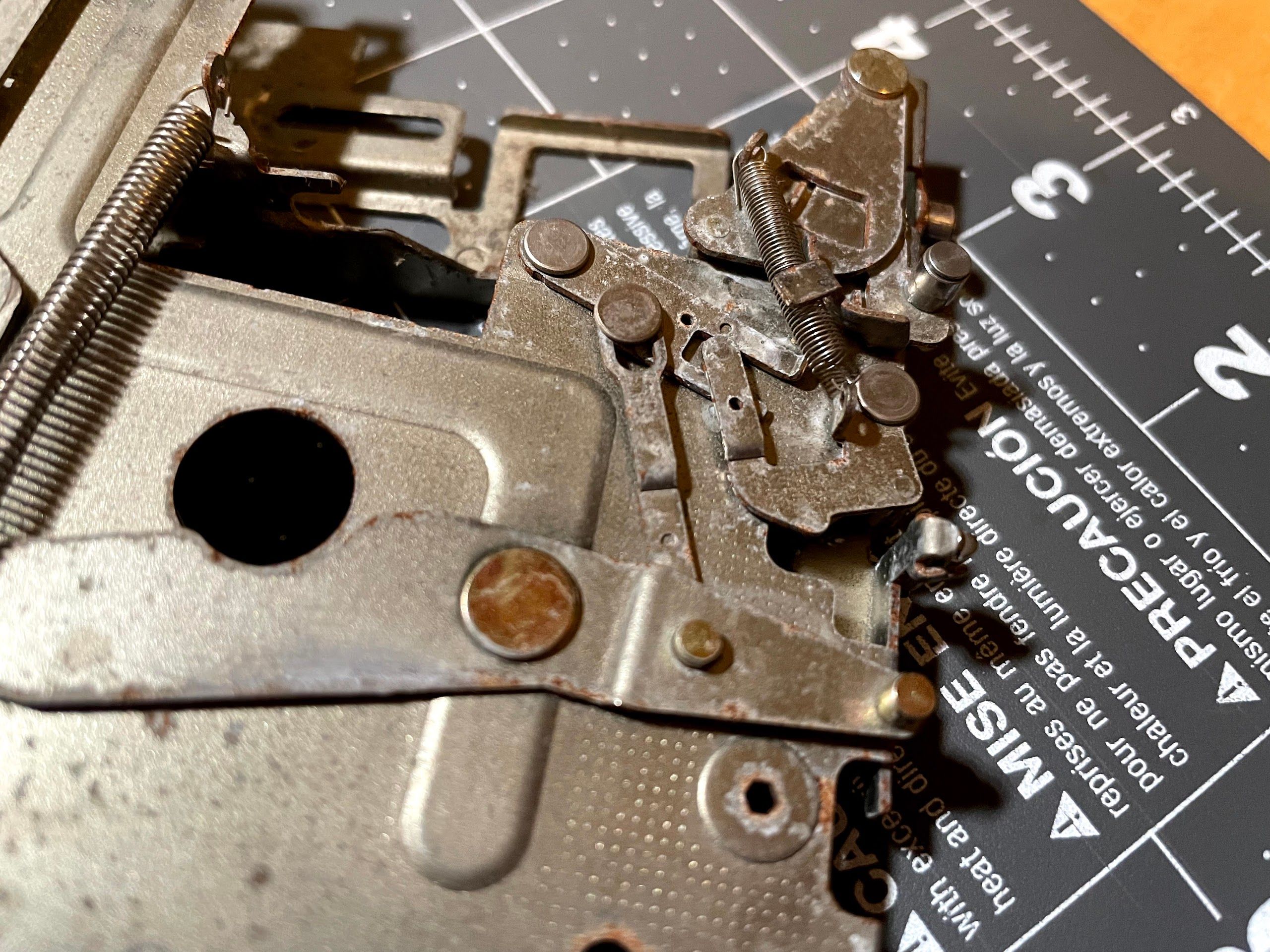

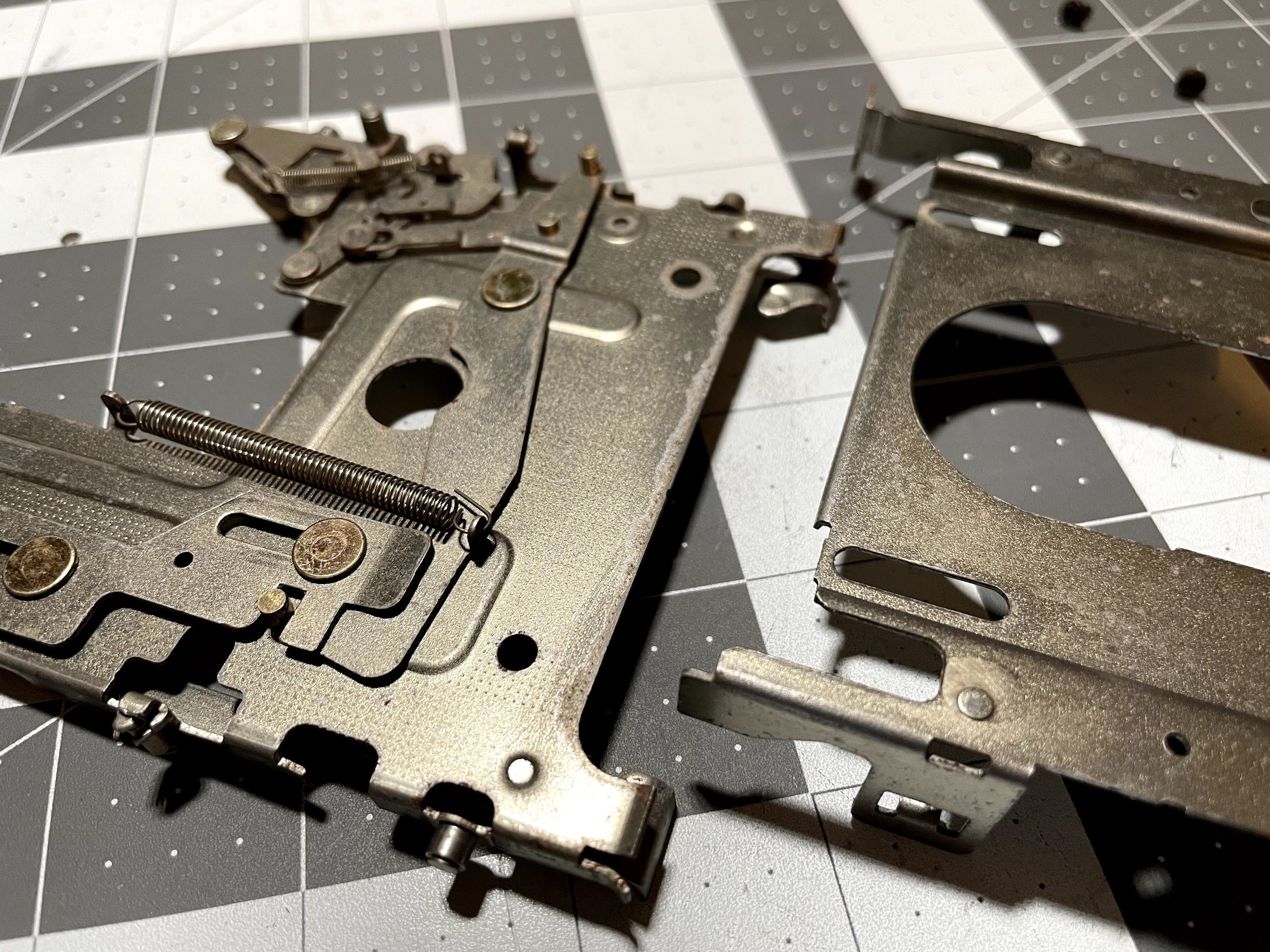

With the eject motor reassembled, I turned my attention to the upper and lower carriages.

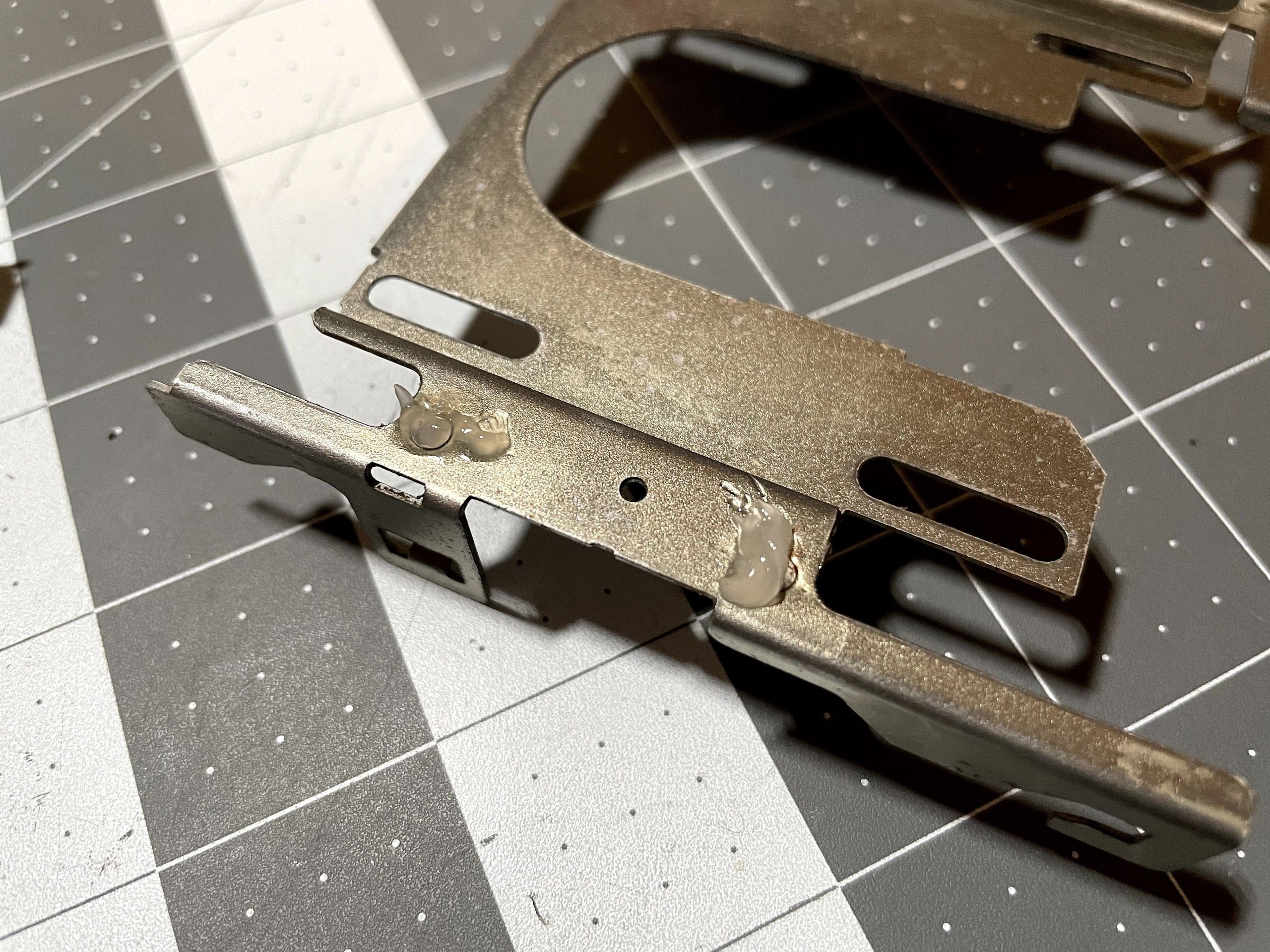

To deal with the rust and corrosion, I scrubbed them down in some vinegar.

After the vinegar, I used dishwasher soap and water, and then dried everything off with the air compressor. Not perfect, but a lot better!

I didn't get any photos of this, but I hit the drive with the air compressor, swabbed the heads with alcohol, and use alcohol and cotton swabs to clean up the linear rail and leadscrew. I dabbed some grease onto them, and it was time to reassemble!

First, I greased the little bumps on the bottom of the lower carriage.

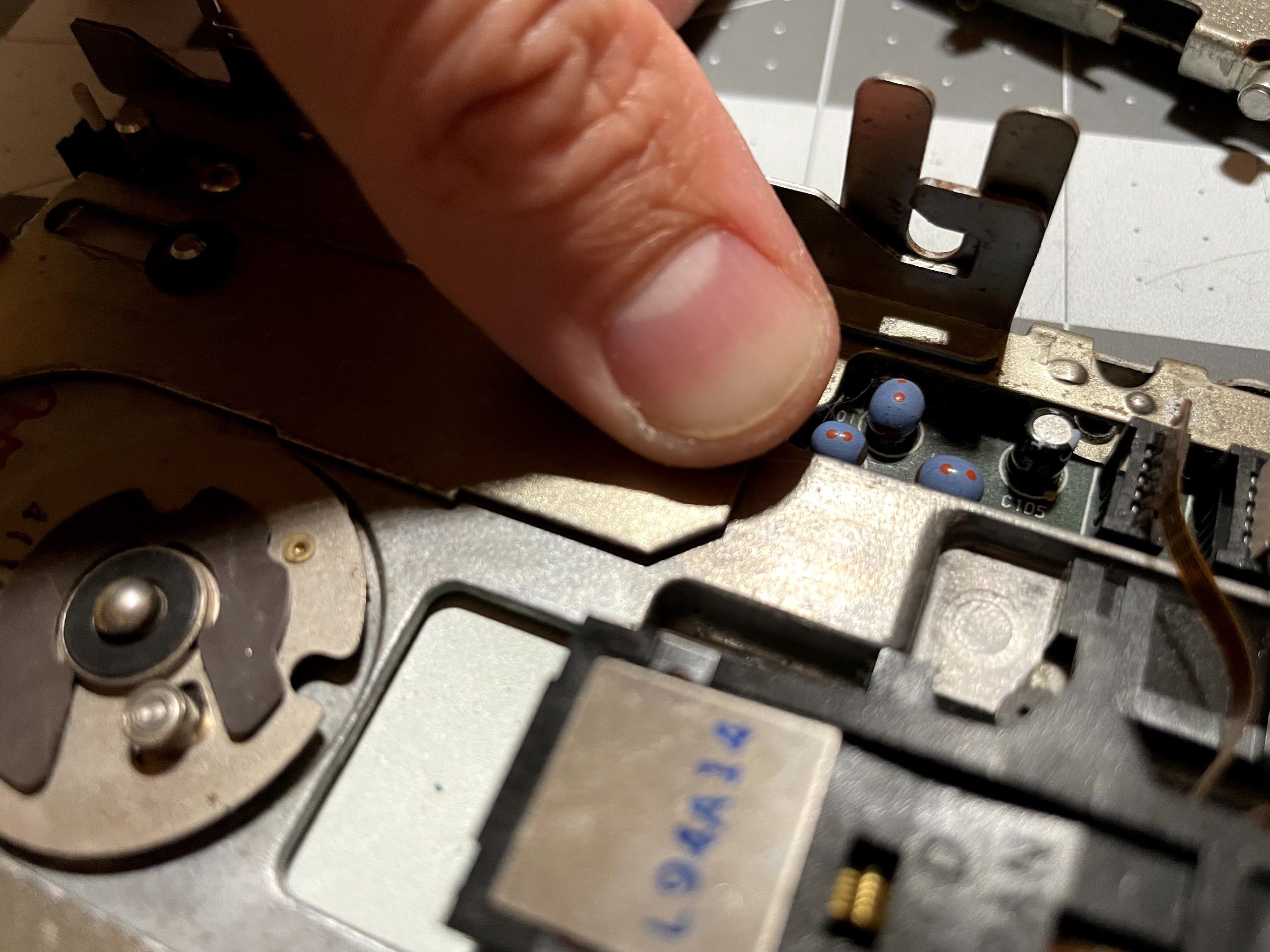

I reinstalled the snap rings by pressing them into place. They take a pretty good push! I usually use the soft, squishy part of my thumb.

I maneuvered the upper carriage back into place, and greased up a few of the moving parts. I don't go crazy with grease... just a bit here and there.

I reattached the springs.

After reinstalling the eject motor, I tested it with a dead floppy disk. At this point, the drive was ready for reinstallation in the Mac!

To deal with the rust and corrosion, I scrubbed them down in some vinegar.

After the vinegar, I used dishwasher soap and water, and then dried everything off with the air compressor. Not perfect, but a lot better!

I didn't get any photos of this, but I hit the drive with the air compressor, swabbed the heads with alcohol, and use alcohol and cotton swabs to clean up the linear rail and leadscrew. I dabbed some grease onto them, and it was time to reassemble!

First, I greased the little bumps on the bottom of the lower carriage.

I reinstalled the snap rings by pressing them into place. They take a pretty good push! I usually use the soft, squishy part of my thumb.

I maneuvered the upper carriage back into place, and greased up a few of the moving parts. I don't go crazy with grease... just a bit here and there.

I reattached the springs.

After reinstalling the eject motor, I tested it with a dead floppy disk. At this point, the drive was ready for reinstallation in the Mac!

Fast forward one last time from May, 2021 to now (which is November, 2021)! We're finally back up to "current", and I'd like to get this restoration finished up as it has been dragging on for about 1.5 years now.

As a first step, I pulled the serviced floppy drive out of storage, and installed it in the machine. I'll spare you the boring details here, but it took a few attempted to get the machine to boot from the drive. Ultimately, it did boot... but I'm going to pull the drive out and take another look at it soon.

For now, let's focus on a hard drive replacement!

As a first step, I pulled the serviced floppy drive out of storage, and installed it in the machine. I'll spare you the boring details here, but it took a few attempted to get the machine to boot from the drive. Ultimately, it did boot... but I'm going to pull the drive out and take another look at it soon.

For now, let's focus on a hard drive replacement!

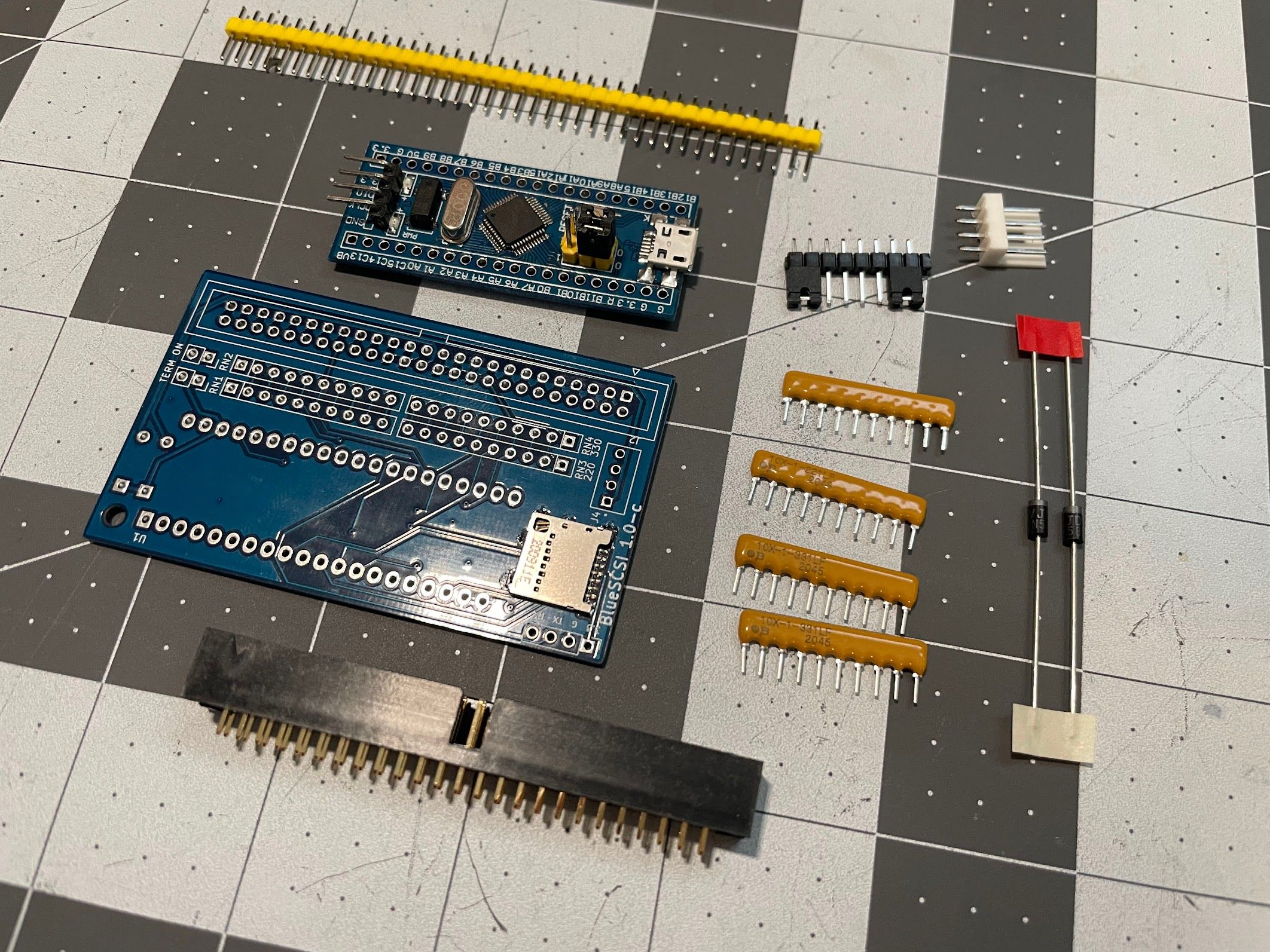

Not only did we lose a Tantalum capacitor on the original MiniScribe drive, but my SE/30 needed a hard drive bracket. To remedy these issues, I decided to build and install BlueSCSI.

I absolutely love these little things, because for about $25 and a MicroSD card, you can have solid-state storage in your retro Mac. There are so many things about this hobby that have become expensive. For storage replacement, that is no longer the case. Buying one is easy - just head over to scsi.blue!

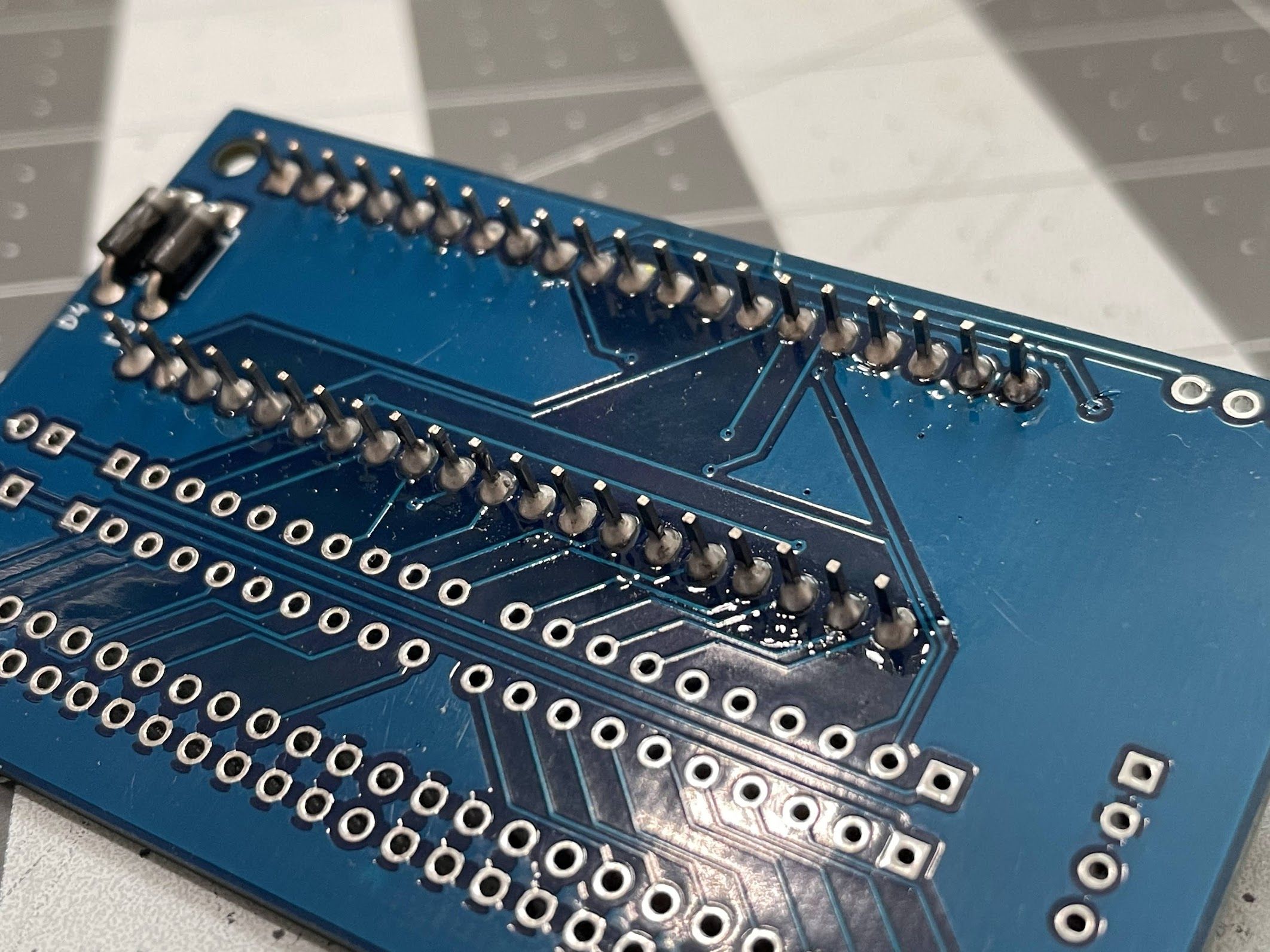

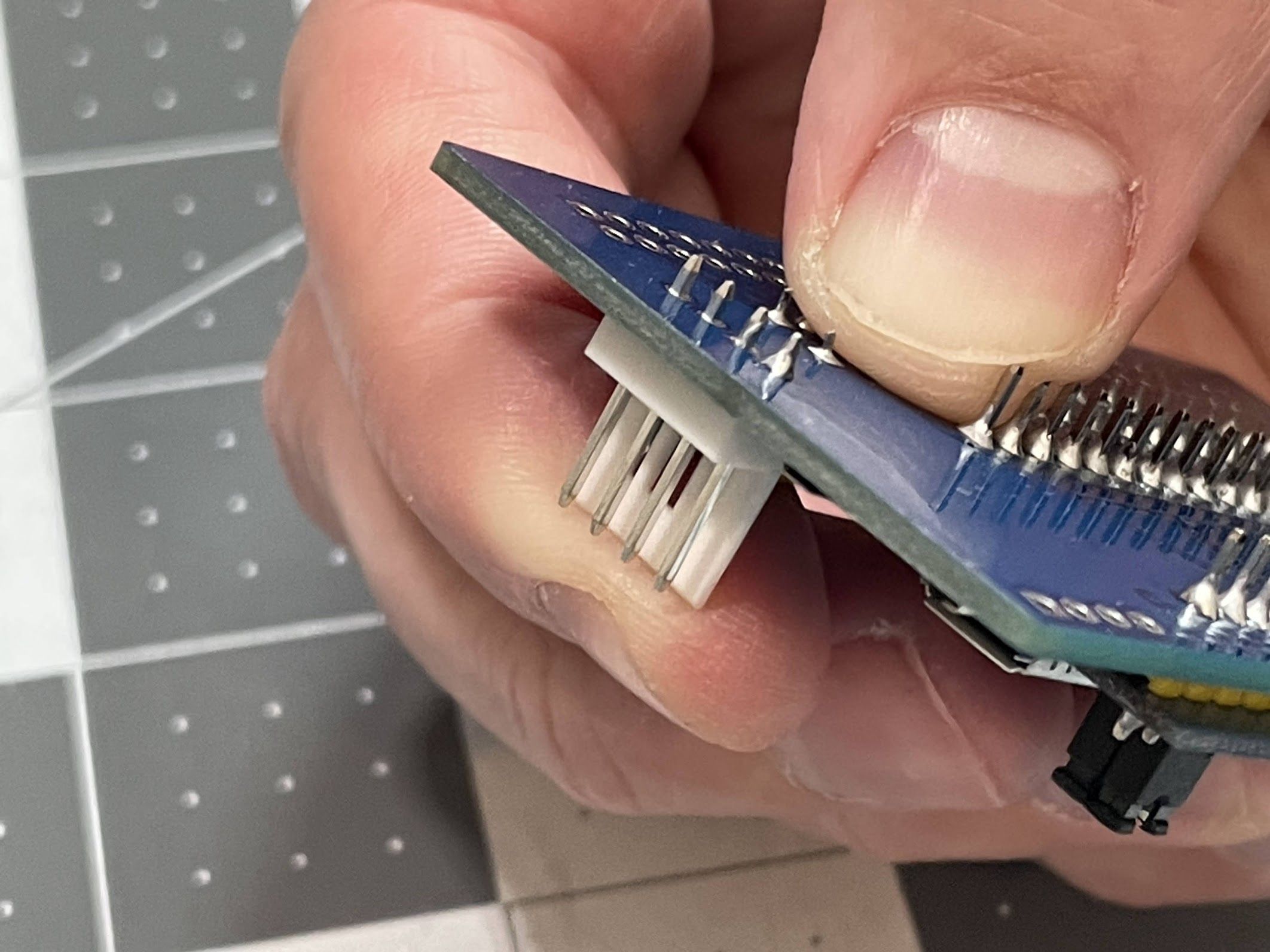

Before we can install it, we need to assemble it.

Eagle-eyed readers may have noticed that the MicroSD card slot is already installed! Awhile back, I used this board to record a quick soldering tutorial:

Part 1: Tack down the part.

Part 2: Solder the pins.

Part 3: Solder the remaining mechanical strength pads.

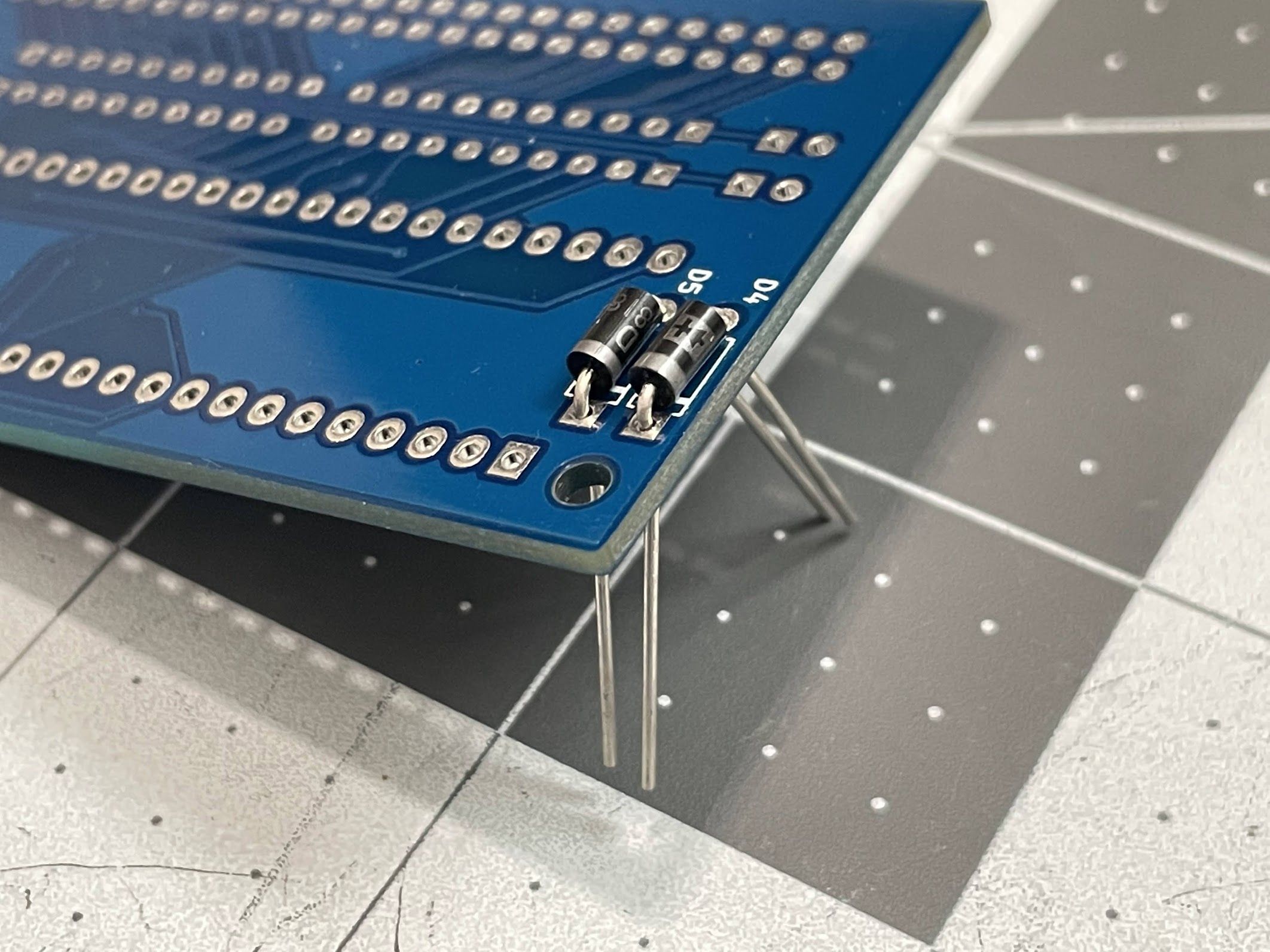

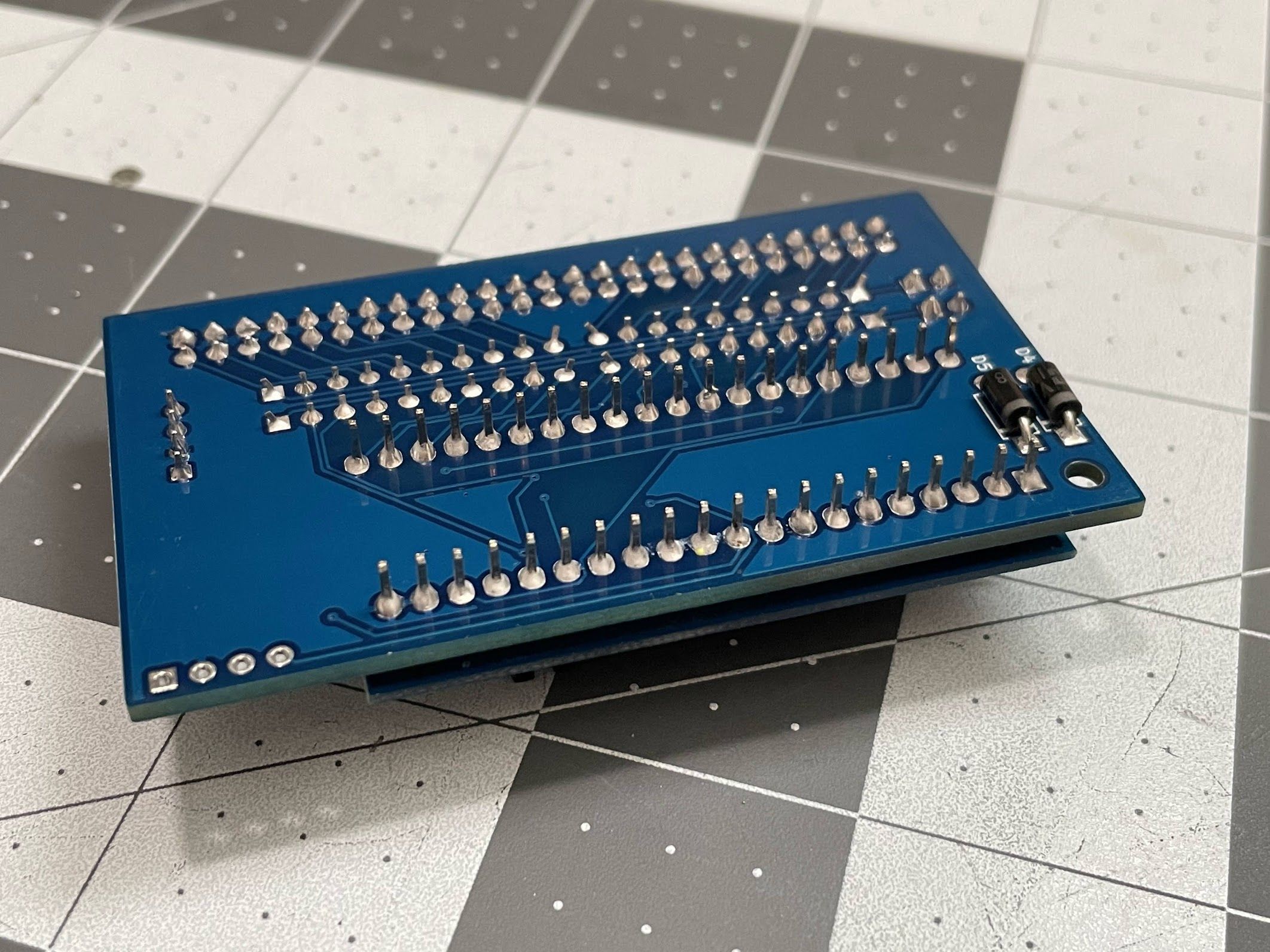

Next, following the BlueSCSI assembly instructions, I solder in the diodes, which go on the bottom. They hold themselves to the board very securely.

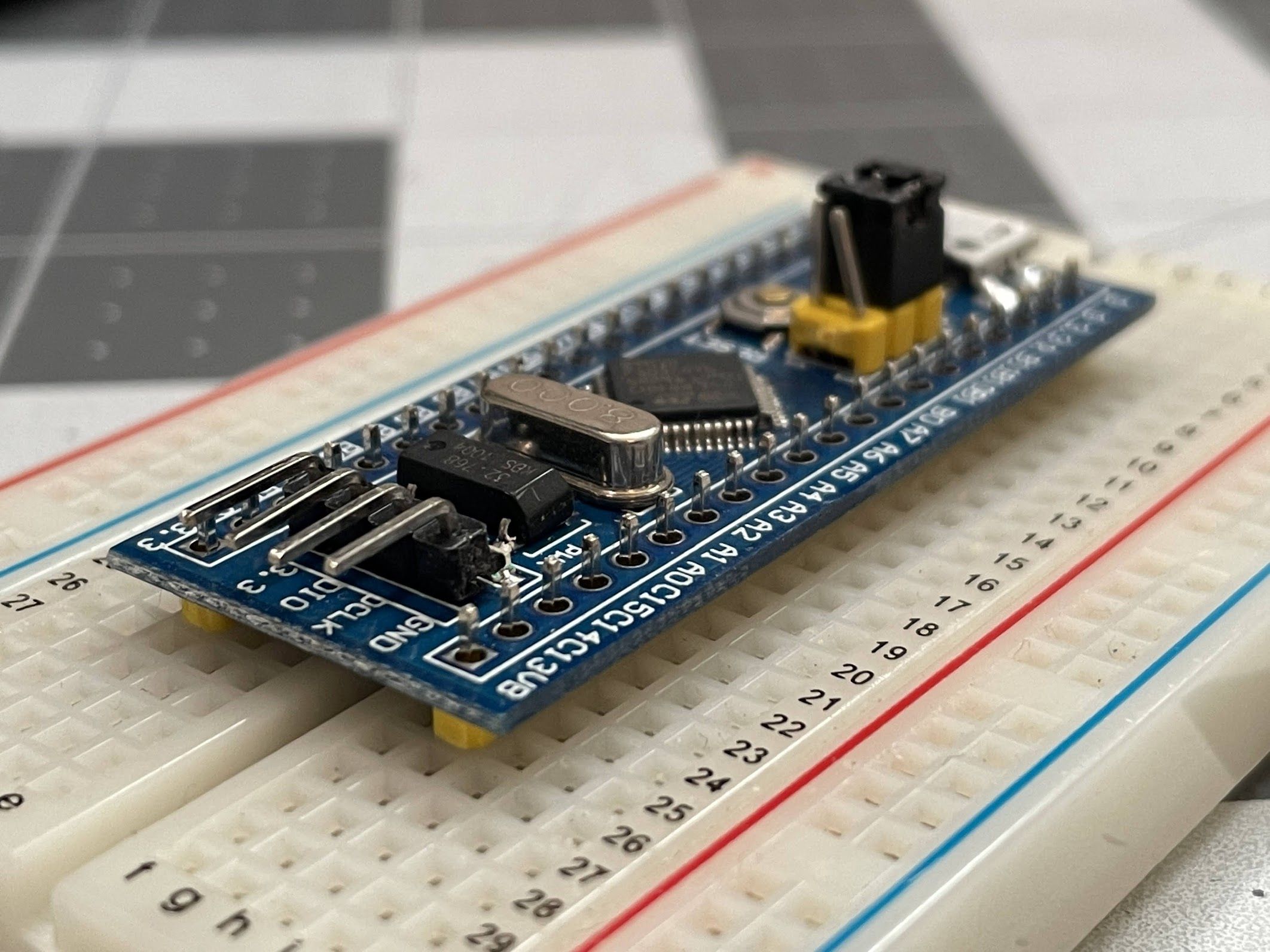

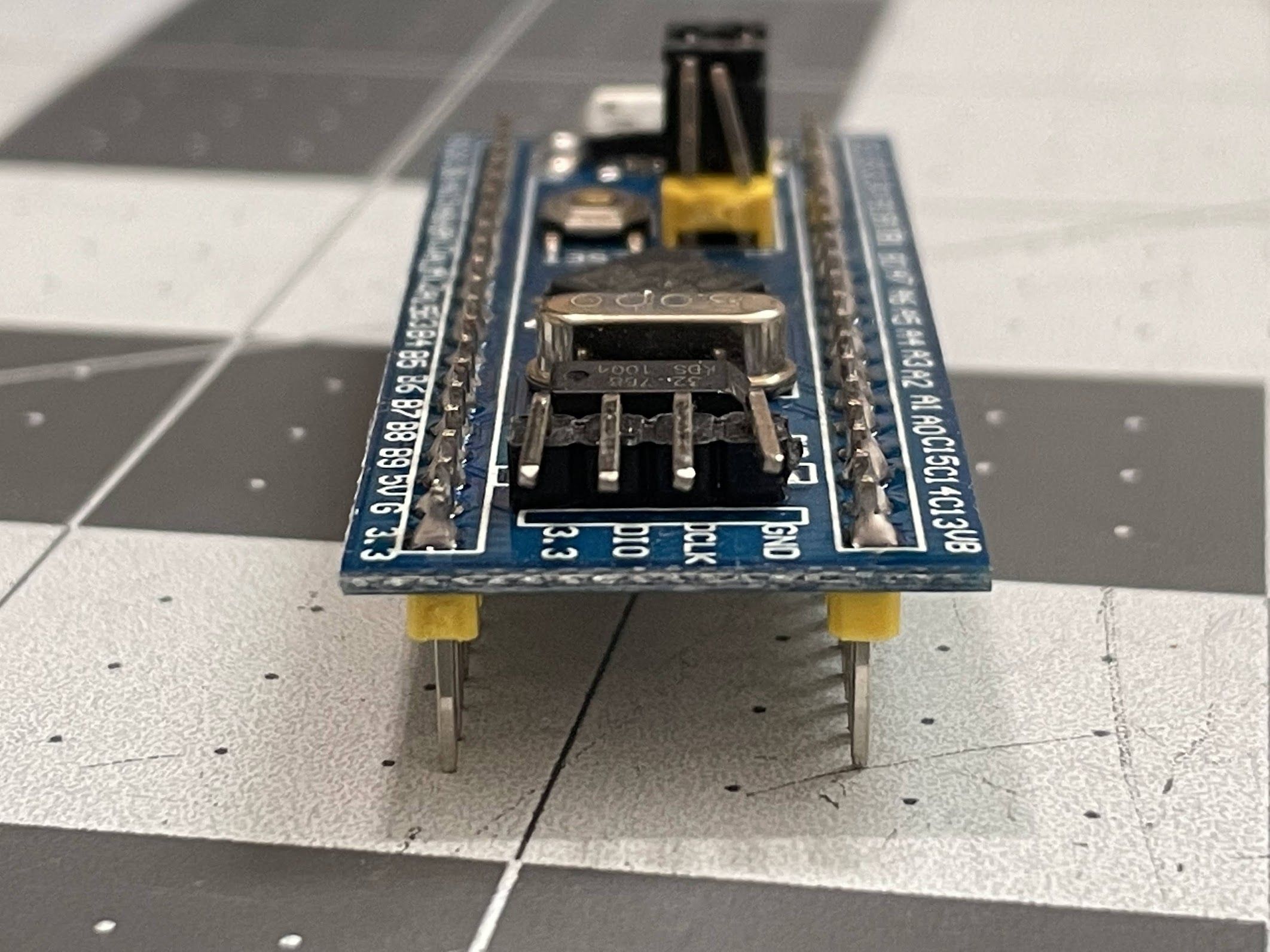

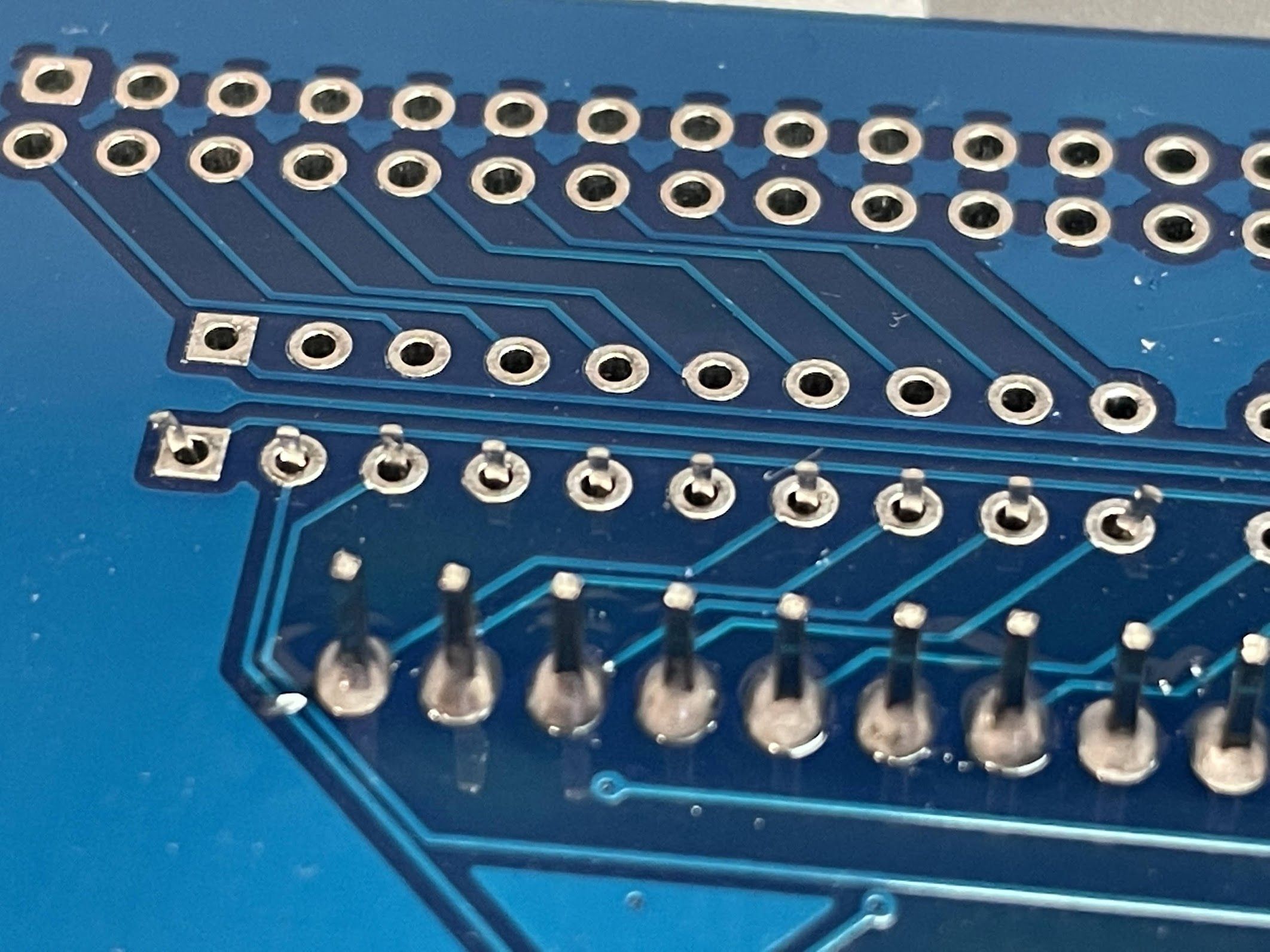

Next, I solder the pin headers to the BluePill. My favorite way to do these is with a breadboard, which holes everything nice and straight for soldering.

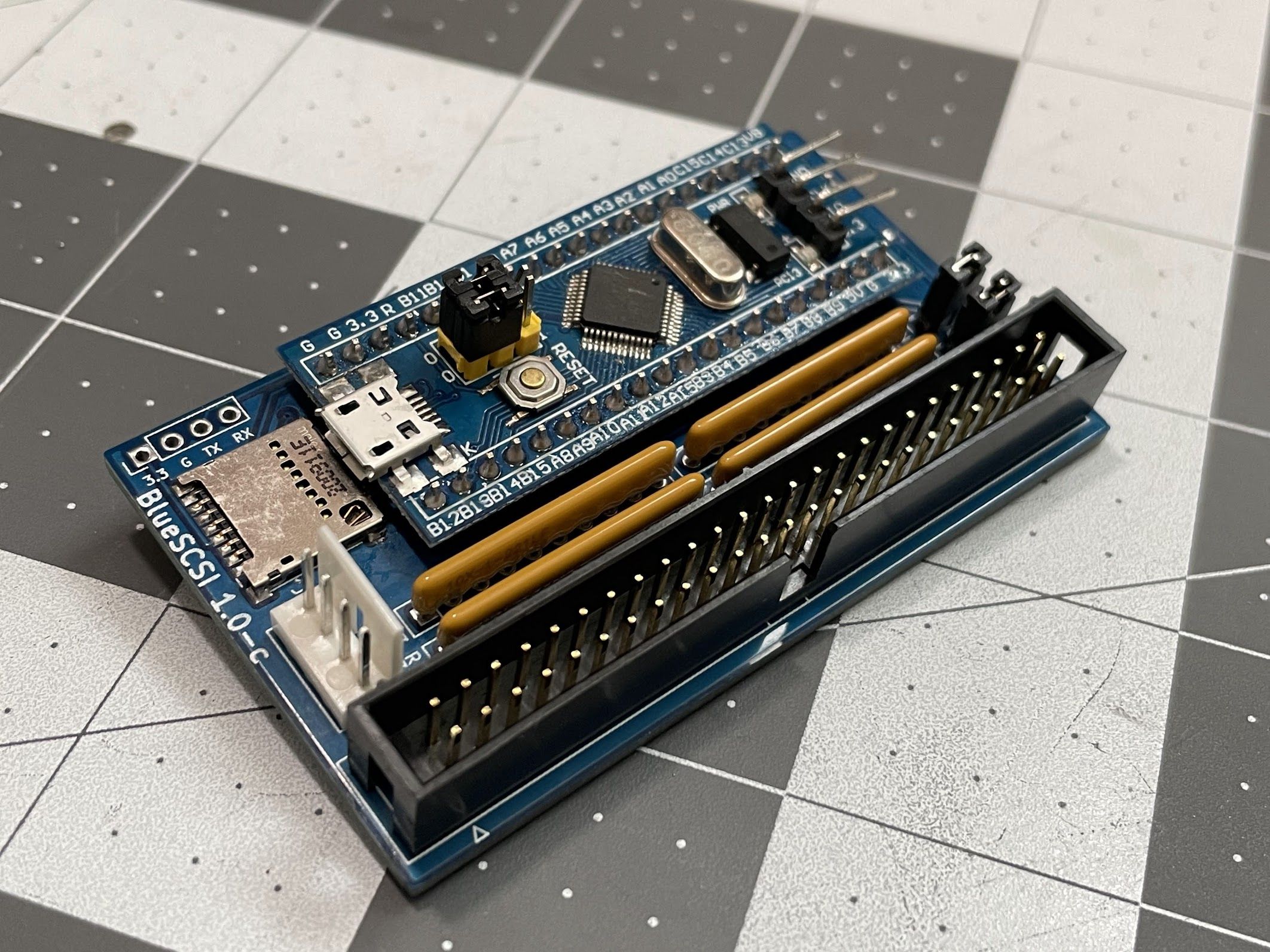

All soldered, and perfectly straight!

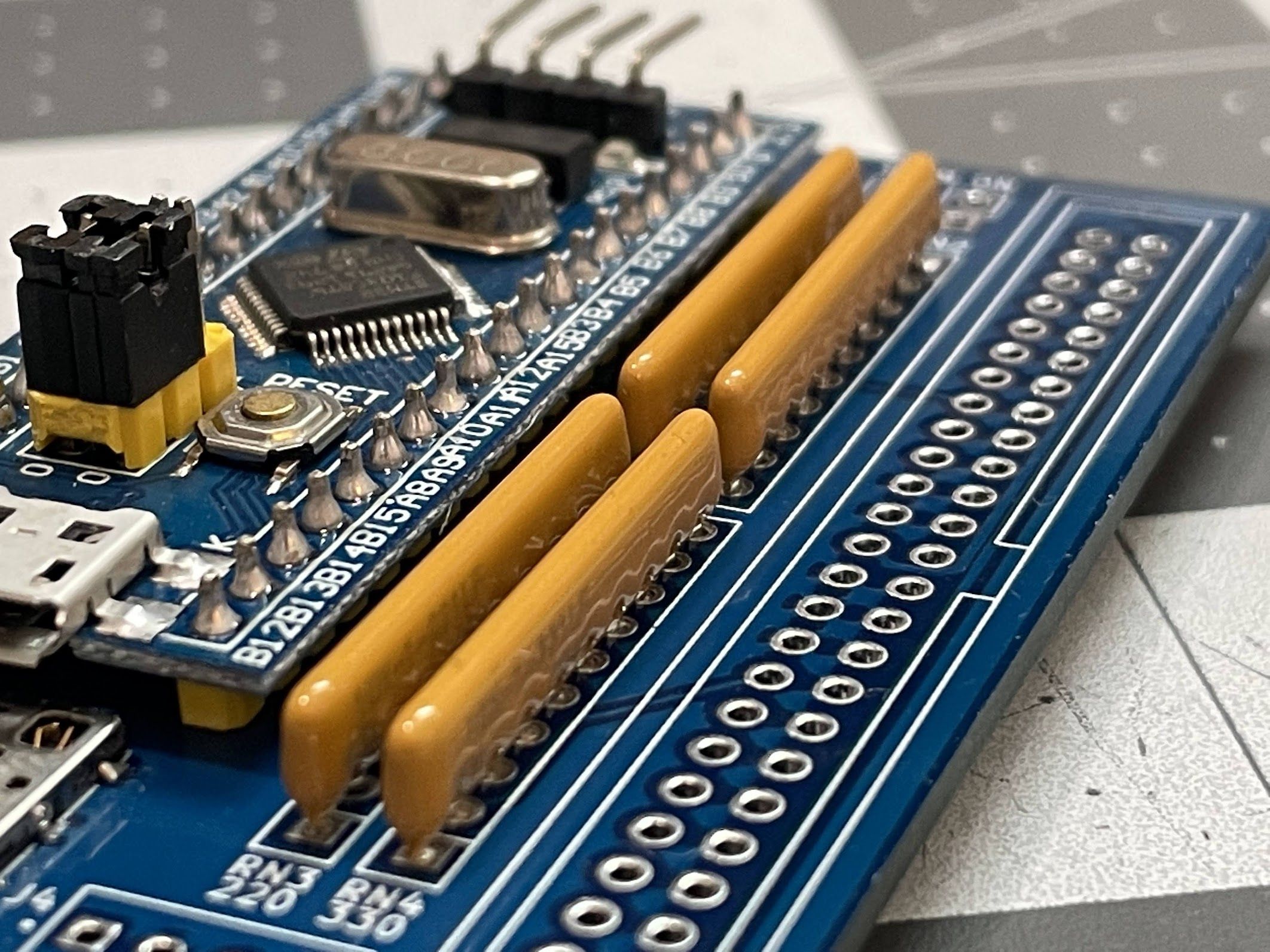

Next, I installed the BluePill onto the BlueSCSI board. Making sure the board is oriented correctly is SUPER important here - if you get it backwards, it's a huge pain to desolder and flip around. Don't ask me how I know!

Also note that I don't cut the header pins off after soldering. You'll see why in awhile.

Next, it's time to install the resistor packs. I always use tweezers to bend the end legs outward slightly to hold it in place for soldering.

Here are the resistor packs, all soldered in!

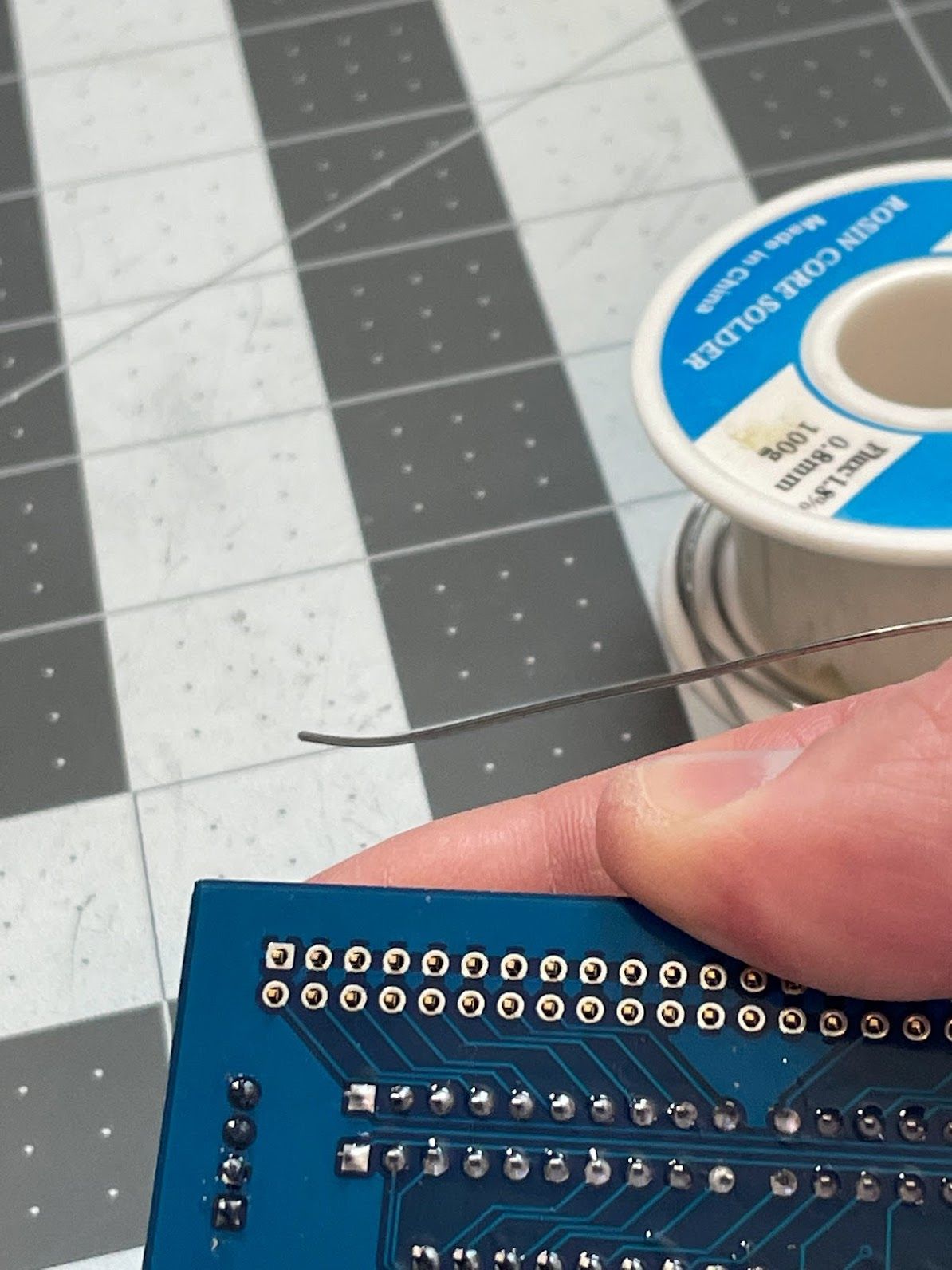

Next, the Molex header for power. I don't need it on this machine, but I like to solder it in for completeness. Getting this one in alone takes a bit of a trick:

1. Bend your solder up in such a way that you can "scoop up some solder" with your iron with only one hand. Fortunately, solder can be formed how you want it, and will do a good job of standing up on it's own.

2. With your non-dominant hand, use your index finger to hold the header in place. Note that I'm holding it in by the plastic so I don't get burned.

3. With your dominant hand, grab your iron, clean it, "scoop up" a generous amount of solder, and touch it to the pad and part for awhile. It will leave a nasty, poorly-flowed joint in place. Before you remove the iron, use your finger to get that header nice and straight. Remove the heat, hold the header still until the solder cools, and the part will now be tacked into place (which you can see in the photo).

4. You can now use two hands to solder the opposite pin.

5. Solder the two middle pins, and then reflow the first pin that you did.

I absolutely love these little things, because for about $25 and a MicroSD card, you can have solid-state storage in your retro Mac. There are so many things about this hobby that have become expensive. For storage replacement, that is no longer the case. Buying one is easy - just head over to scsi.blue!

Before we can install it, we need to assemble it.

Eagle-eyed readers may have noticed that the MicroSD card slot is already installed! Awhile back, I used this board to record a quick soldering tutorial:

Part 1: Tack down the part.

Part 2: Solder the pins.

Part 3: Solder the remaining mechanical strength pads.

Next, following the BlueSCSI assembly instructions, I solder in the diodes, which go on the bottom. They hold themselves to the board very securely.

Next, I solder the pin headers to the BluePill. My favorite way to do these is with a breadboard, which holes everything nice and straight for soldering.

All soldered, and perfectly straight!

Next, I installed the BluePill onto the BlueSCSI board. Making sure the board is oriented correctly is SUPER important here - if you get it backwards, it's a huge pain to desolder and flip around. Don't ask me how I know!

Also note that I don't cut the header pins off after soldering. You'll see why in awhile.

Next, it's time to install the resistor packs. I always use tweezers to bend the end legs outward slightly to hold it in place for soldering.

Here are the resistor packs, all soldered in!

Next, the Molex header for power. I don't need it on this machine, but I like to solder it in for completeness. Getting this one in alone takes a bit of a trick:

1. Bend your solder up in such a way that you can "scoop up some solder" with your iron with only one hand. Fortunately, solder can be formed how you want it, and will do a good job of standing up on it's own.

2. With your non-dominant hand, use your index finger to hold the header in place. Note that I'm holding it in by the plastic so I don't get burned.

3. With your dominant hand, grab your iron, clean it, "scoop up" a generous amount of solder, and touch it to the pad and part for awhile. It will leave a nasty, poorly-flowed joint in place. Before you remove the iron, use your finger to get that header nice and straight. Remove the heat, hold the header still until the solder cools, and the part will now be tacked into place (which you can see in the photo).

4. You can now use two hands to solder the opposite pin.

5. Solder the two middle pins, and then reflow the first pin that you did.

I employ the same technique on the termination headers. Hold the part with one hand, use the other to tack it in...

...and then go back and "do it right".

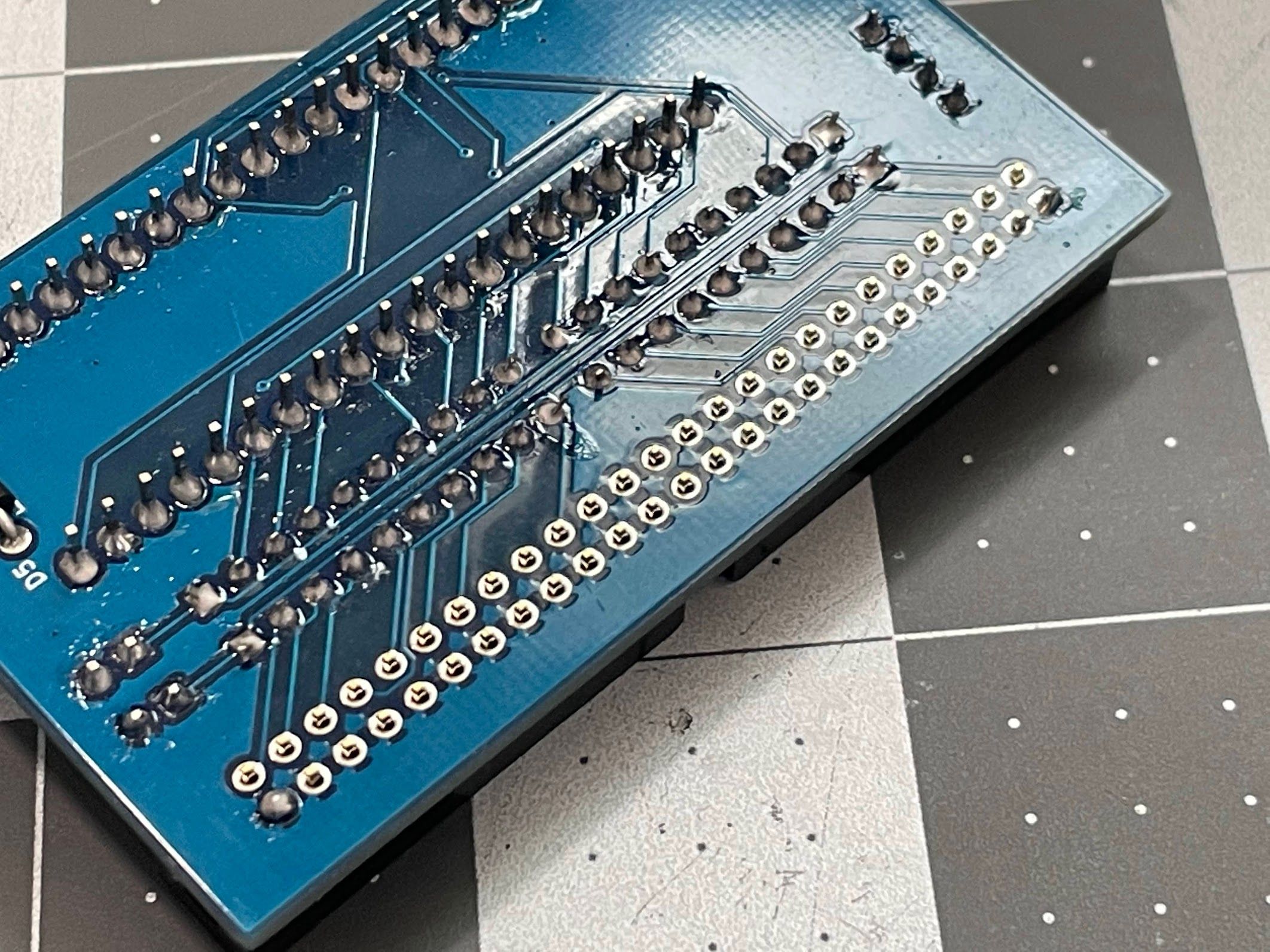

Finally, we can solder in the SCSI connector. I have a trick for these too:

1. Pick a pin in a corner, and solder it into place.

2. Push the header towards the board, and reheat the joint. The header will settle against the board.

3. Do the same thing on the opposite corner.

Your header is now perfectly flush with the board, and you can solder the rest of the pins.

Next, I scrubbed the bottom of the board with Dawn and water, and hit it with the air compressor. It looks so nice and clean!

I wish I could say the same about the top, which I only used alcohol to clean.

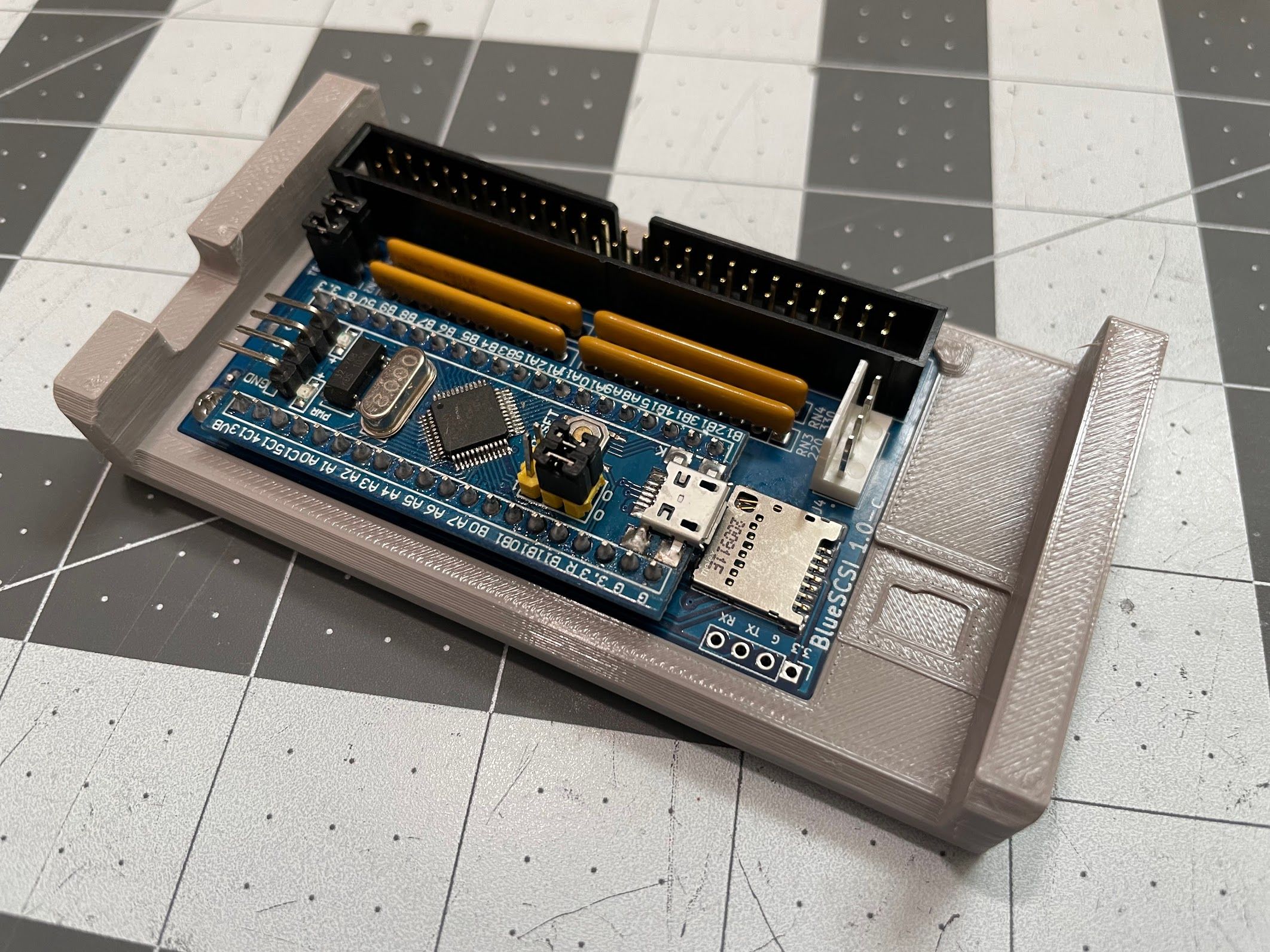

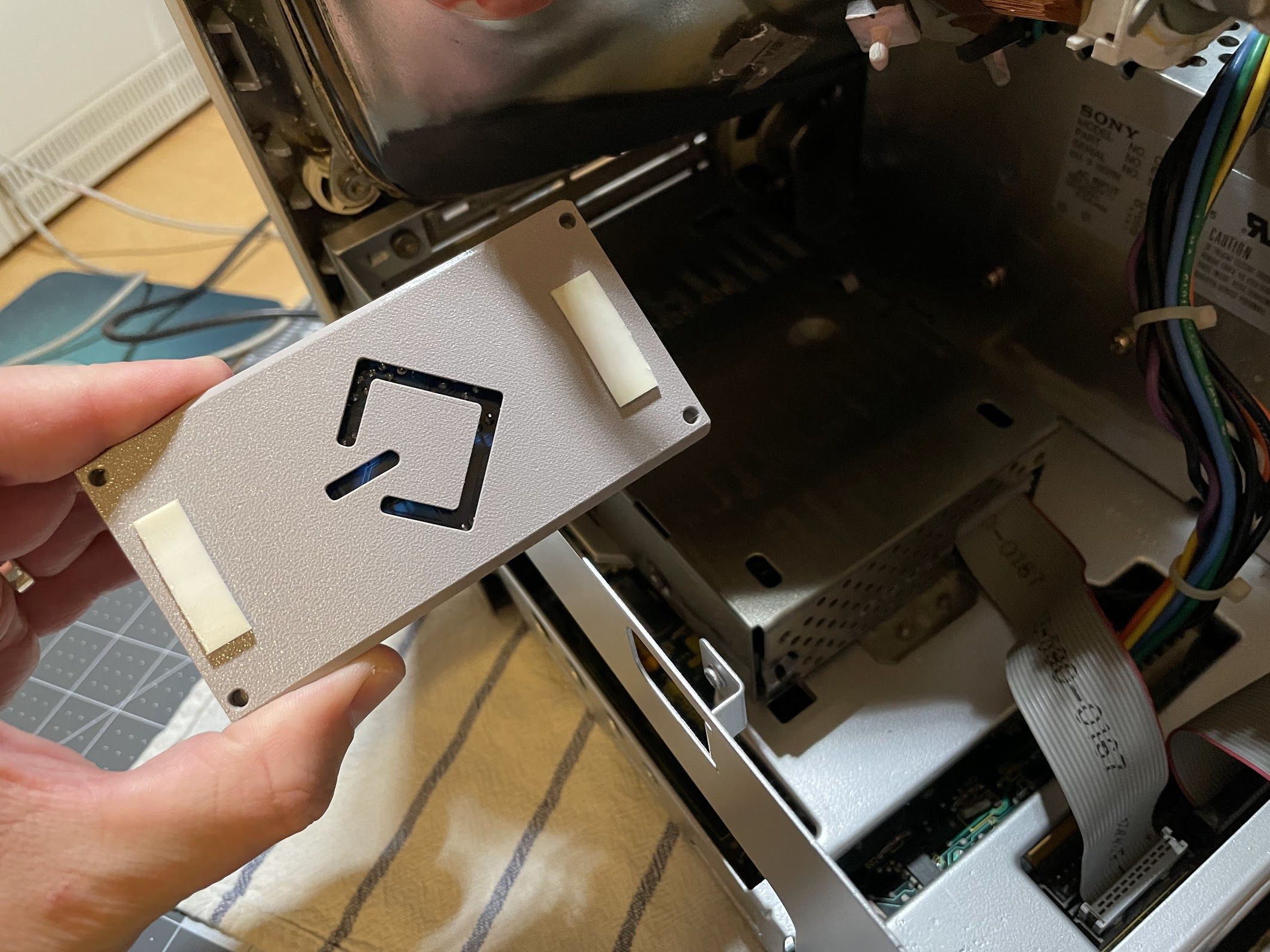

Finally, I installed the BlueSCSI into one of my printed brackets. If you'd like, you can get the files to print your own, or you can buy them on my Etsy store. The BlueSCSI hooks under the tabs on the front, and snaps down flush with the bracket.

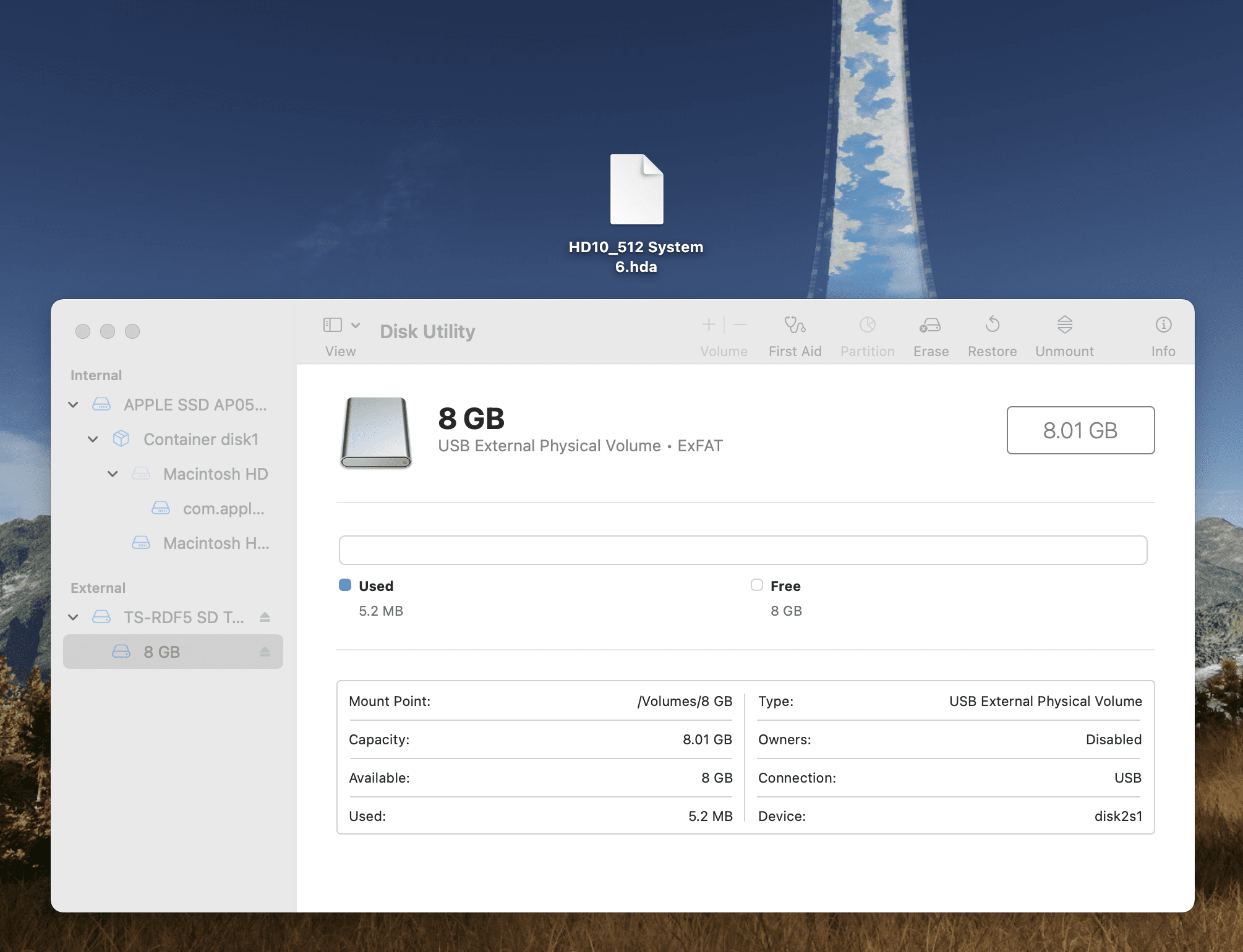

There was one last thing to do, which was set up the MicroSD card. First, I formatted my 8 GB card as ExFat using Disk Utility on macOS 11.6 Big Sur.

Next, I grabbed a RaSCSI System 6.0.8 Boot image from Macintosh Garden. These are intended for use with the RaSCSI, but they work on the BlueSCSI and are so, SO convenient. I unzipped the image, and renamed it to "HD10_512 System 6.hda". If everything works right, this system will boot to a working copy of System 6.0.8, which is super convenient! From a software perspective, the BlueSCSI is insanely easy to use - I love it.

...and then go back and "do it right".

Finally, we can solder in the SCSI connector. I have a trick for these too:

1. Pick a pin in a corner, and solder it into place.

2. Push the header towards the board, and reheat the joint. The header will settle against the board.

3. Do the same thing on the opposite corner.

Your header is now perfectly flush with the board, and you can solder the rest of the pins.

Next, I scrubbed the bottom of the board with Dawn and water, and hit it with the air compressor. It looks so nice and clean!

I wish I could say the same about the top, which I only used alcohol to clean.

Finally, I installed the BlueSCSI into one of my printed brackets. If you'd like, you can get the files to print your own, or you can buy them on my Etsy store. The BlueSCSI hooks under the tabs on the front, and snaps down flush with the bracket.

There was one last thing to do, which was set up the MicroSD card. First, I formatted my 8 GB card as ExFat using Disk Utility on macOS 11.6 Big Sur.

Next, I grabbed a RaSCSI System 6.0.8 Boot image from Macintosh Garden. These are intended for use with the RaSCSI, but they work on the BlueSCSI and are so, SO convenient. I unzipped the image, and renamed it to "HD10_512 System 6.hda". If everything works right, this system will boot to a working copy of System 6.0.8, which is super convenient! From a software perspective, the BlueSCSI is insanely easy to use - I love it.

Ok, just a couple things left on this Mac! It's coming together! It's almost done!

No, no. I can't leave it. It can be so, so much better.

Time to take it back apart. Again.

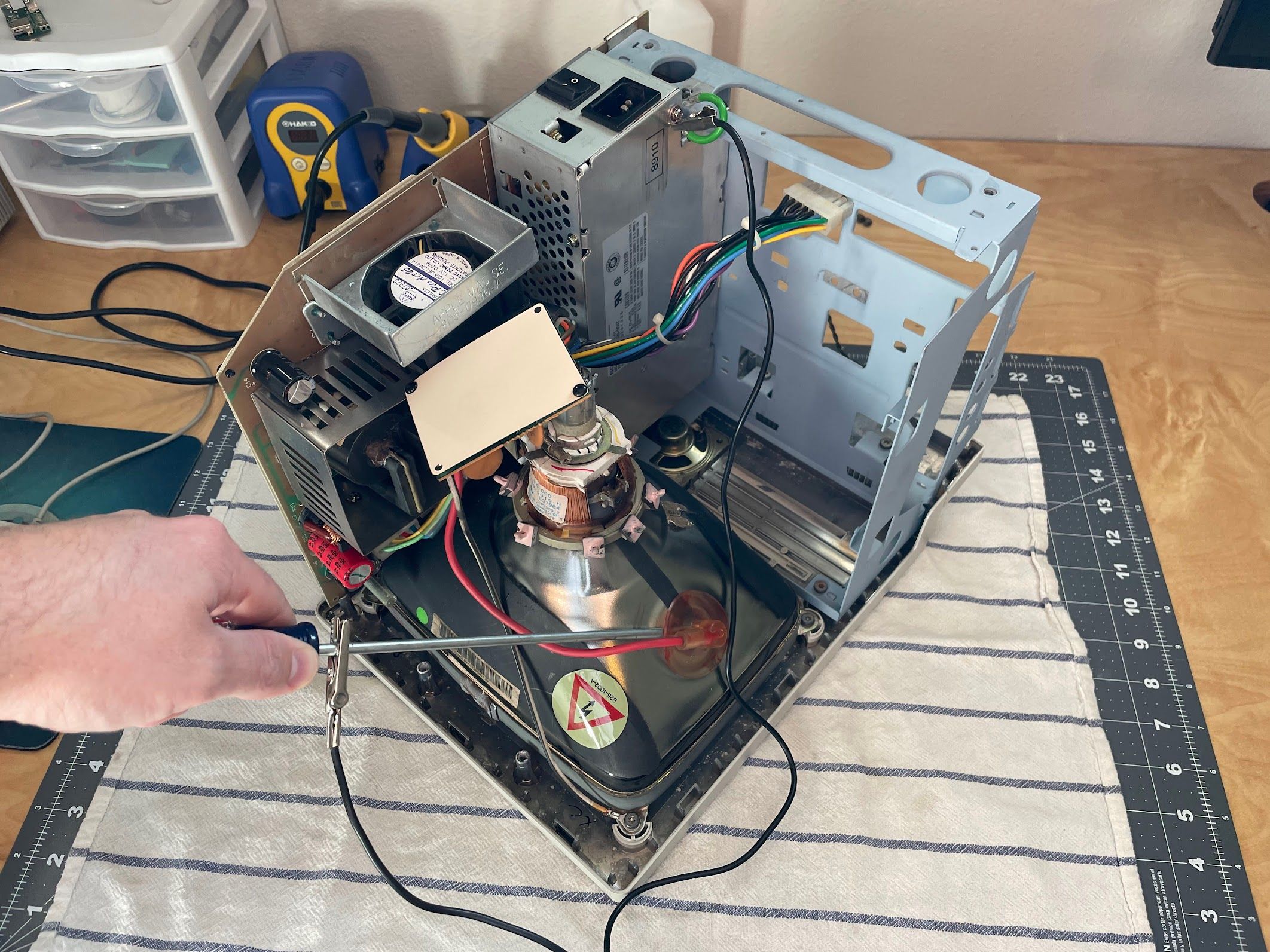

I may be anxious to get it fixed up, and while the SE does have a bleeder resistor for the CRT... safety first. I always discharge the CRT before touching the anode cap, anode wire, and flyback.

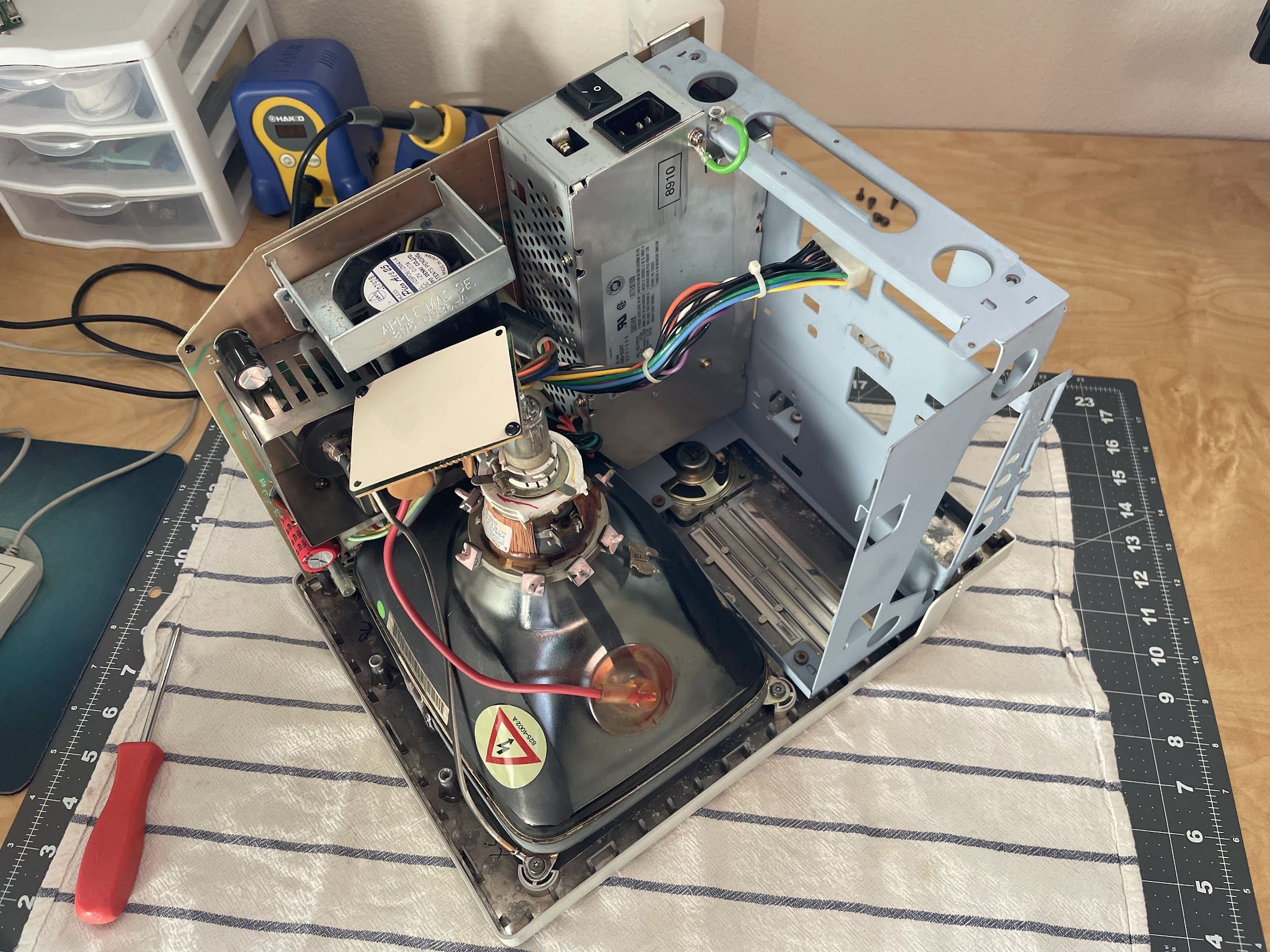

Here it is all taken apart, littering the floor of my office. Again. I didn't even bother to disconnect the ground wire!

Next, I desoldered the shield from the logic board. Do you see where this is going yet?

No, no. I can't leave it. It can be so, so much better.

Time to take it back apart. Again.

I may be anxious to get it fixed up, and while the SE does have a bleeder resistor for the CRT... safety first. I always discharge the CRT before touching the anode cap, anode wire, and flyback.

Here it is all taken apart, littering the floor of my office. Again. I didn't even bother to disconnect the ground wire!

Next, I desoldered the shield from the logic board. Do you see where this is going yet?

Last edited:

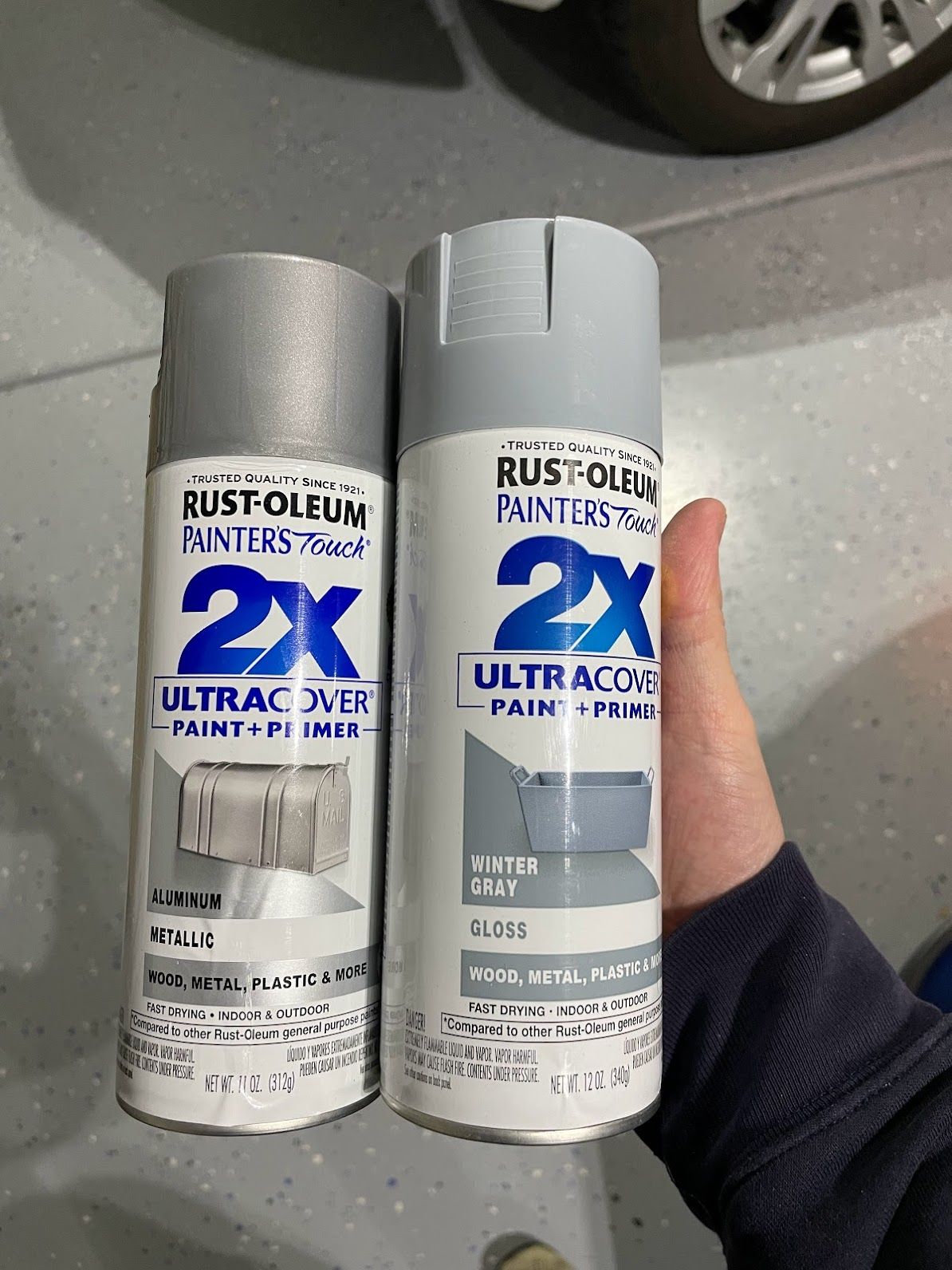

The blue chassis just wasn't working for me. I had to paint it. I had to. I grabbed a couple of cans of paint at Home Cheapo, and ultimately chose the Metallic Aluminum Rust-Oleum 2X.

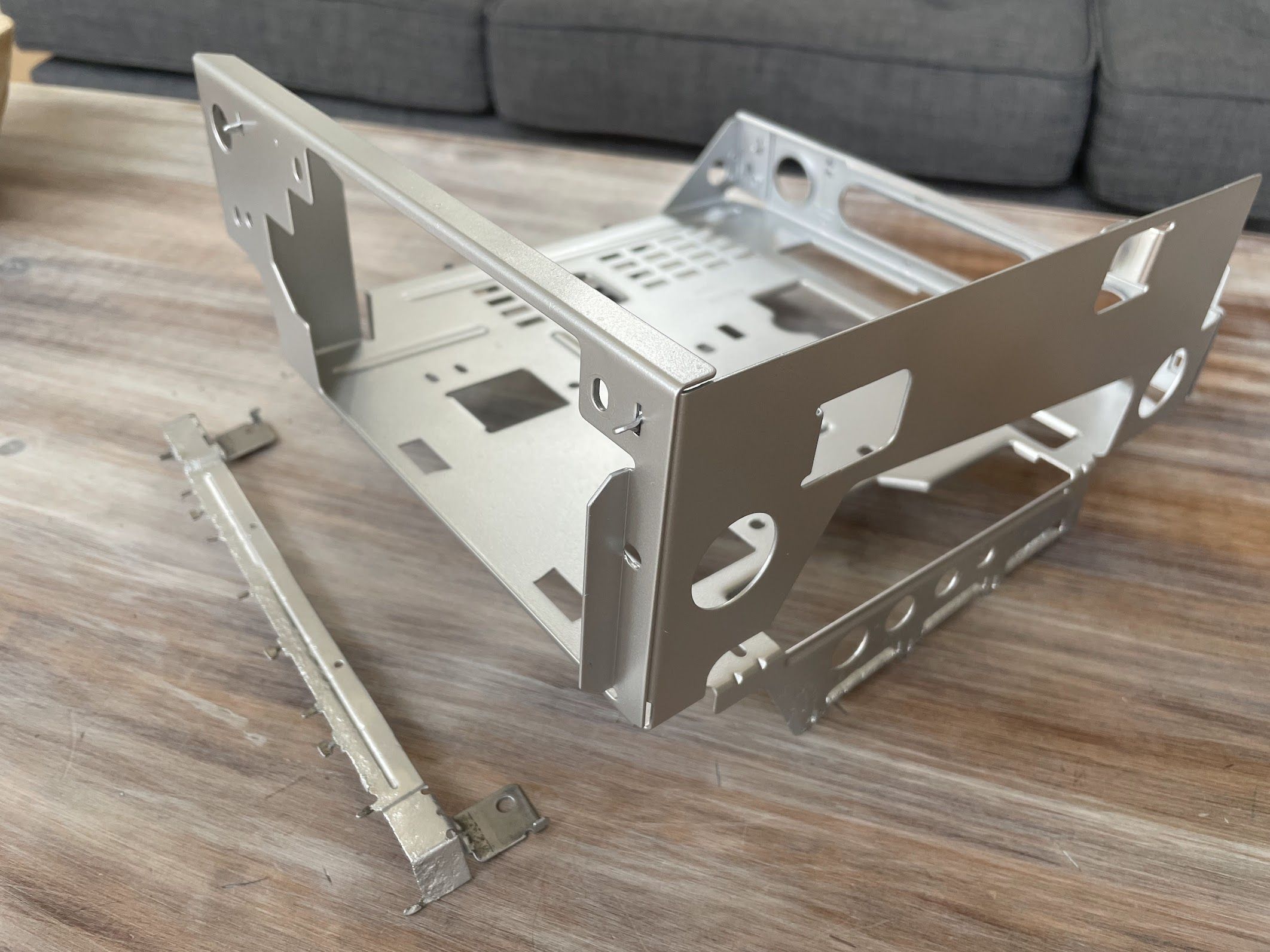

I found a place to hang them up in the back yard, and hit them with their first coat of paint.

Since it's pretty cold outside, I took them straight inside and hung them up in the laundry room.

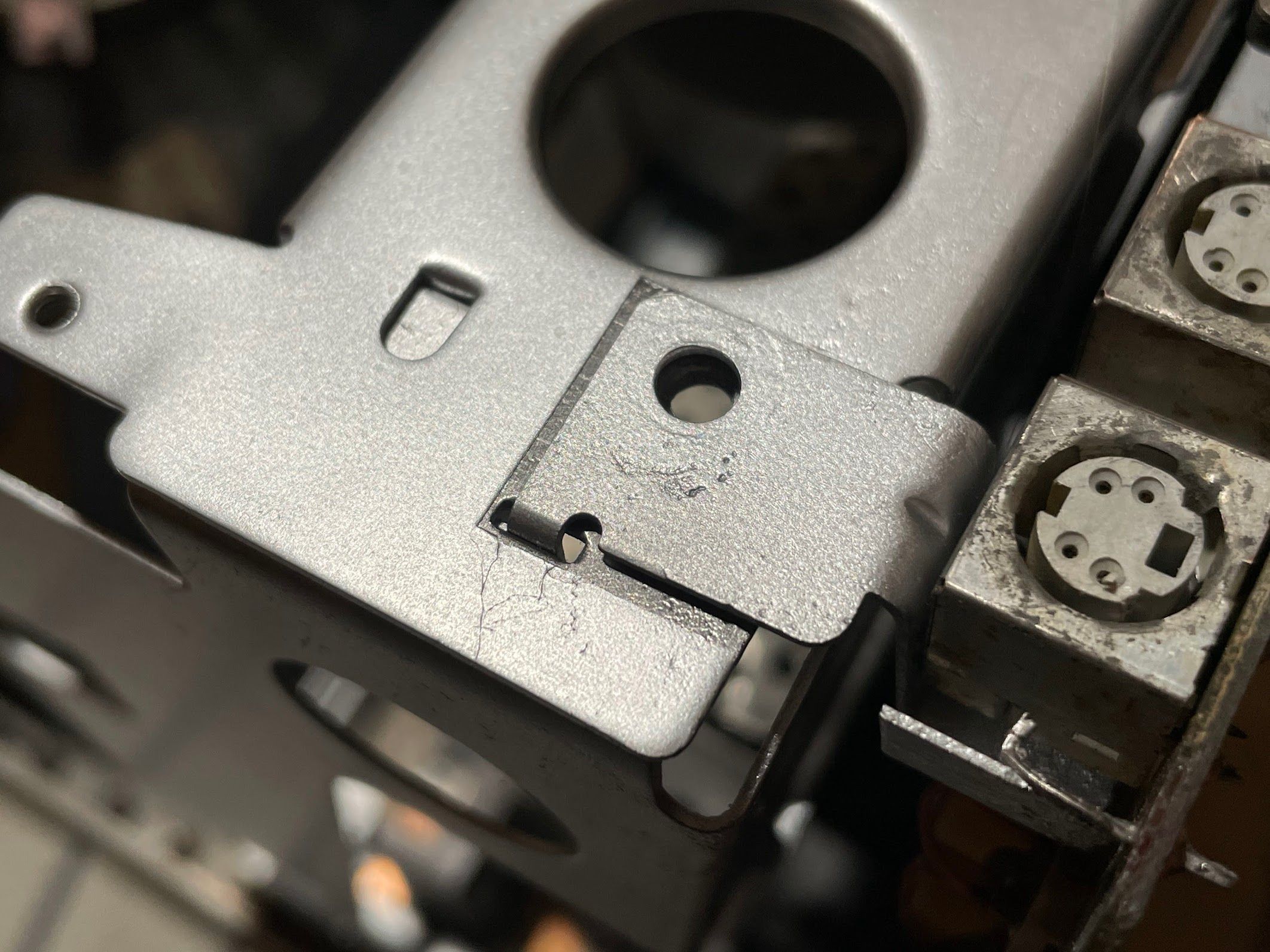

In my excitement, I forgot to mask off some important places for grounding, so after things had dried overnight, I hit some places with the wire wheel and some 220-grit sandpaper.

I masked things off, and hit both parts with a couple more coats of paint.

I'm really, REALLY happy with how these turned out!

After it had a couple of days to dry, I put everything back together, including soldering the shield back on the logic board (again). As for masking and grounding, I only worried about three points:

1. Where the ground wire attaches from the analog board

2. The two places where the logic board shield touches the back of the chassis

Other than maybe the floppy drive, I couldn't find any other places for grounding. I also checked for continuity for grounds everywhere, and it all checked out. Considering that you can easily run these machines outside of their cases on a bench, I think this will be 100 percent fine.

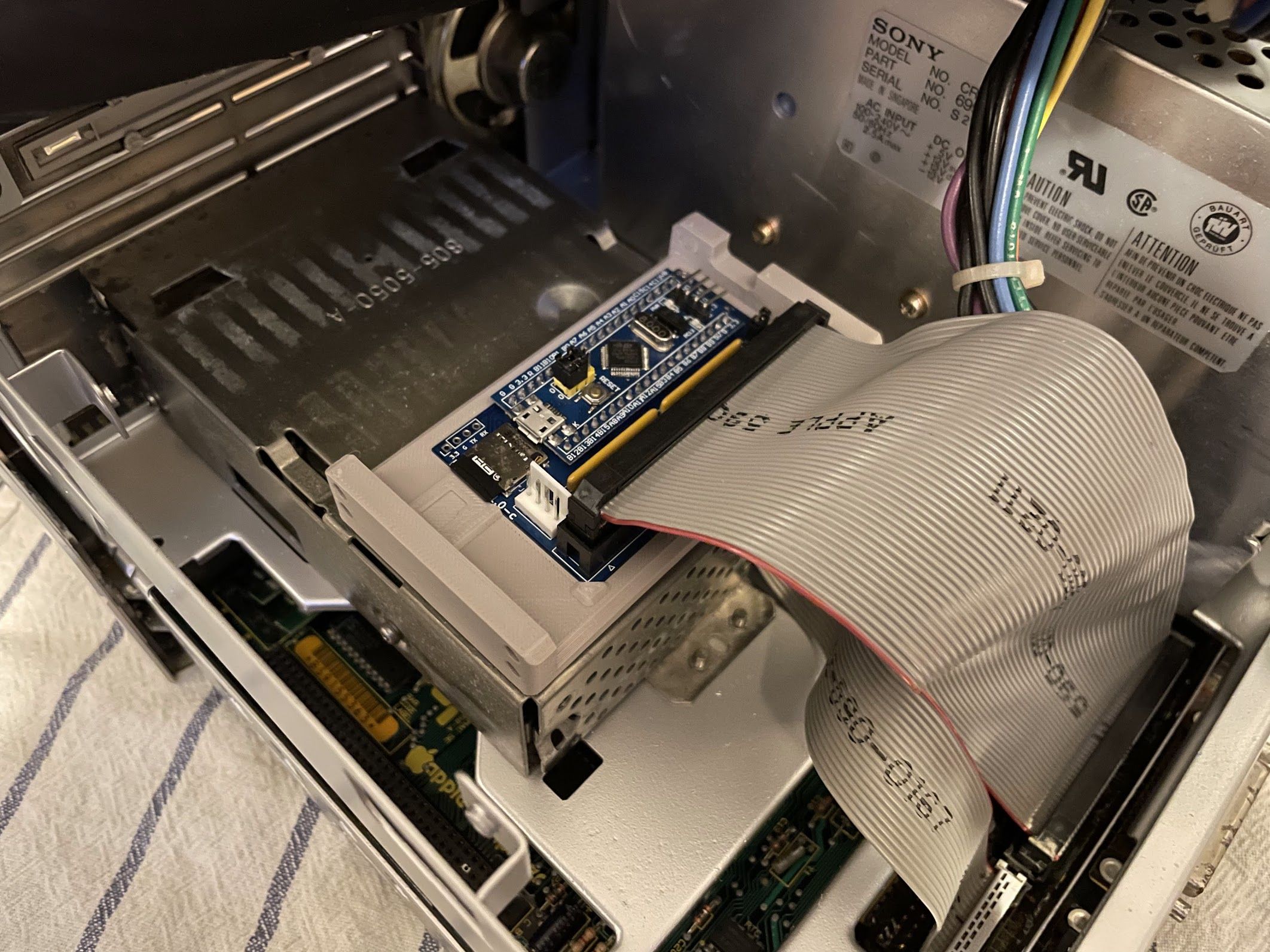

Finally, I installed the BlueSCSI. Since I stole the hard drive bracket for my SE/30, I just used a couple pieces of double-side tape on the back of the BlueSCSI bracket.

Then, I stuck it to the top of the floppy drive bracket.

I found a place to hang them up in the back yard, and hit them with their first coat of paint.

Since it's pretty cold outside, I took them straight inside and hung them up in the laundry room.

In my excitement, I forgot to mask off some important places for grounding, so after things had dried overnight, I hit some places with the wire wheel and some 220-grit sandpaper.

I masked things off, and hit both parts with a couple more coats of paint.

I'm really, REALLY happy with how these turned out!

After it had a couple of days to dry, I put everything back together, including soldering the shield back on the logic board (again). As for masking and grounding, I only worried about three points:

1. Where the ground wire attaches from the analog board

2. The two places where the logic board shield touches the back of the chassis

Other than maybe the floppy drive, I couldn't find any other places for grounding. I also checked for continuity for grounds everywhere, and it all checked out. Considering that you can easily run these machines outside of their cases on a bench, I think this will be 100 percent fine.

Finally, I installed the BlueSCSI. Since I stole the hard drive bracket for my SE/30, I just used a couple pieces of double-side tape on the back of the BlueSCSI bracket.

Then, I stuck it to the top of the floppy drive bracket.

Last edited: