you could use prusa slicer to watch the filesI can open and rotate STL files merely by selecting the file on my Mac and pressing the Spacebar for QuickLook, but how are STP files viewed?

3D Printing & MacEffects Appreciation

- Thread starter wottle

- Start date

-

- Tags

- maceffects

-

Please can you read through and vote on the following proposition for changes to the board structure by clicking here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

actually, this was not supposed to get posted yet, i will mend it today once i found the correct filesIbook G3 battery pack

Oh, found another one, this one is tricky to print, and im not 100% happy with it but it is the Ibook G3 battery pack shells, i have assembled a pack like this and it does all fit, but it is not as strong as i want it to be.

i forgot the STP file there, so i have added it. IPT is for inventor

it might be that STL files are natively supported and STP files are not, i generally use Linux, so i would not knowI can open and rotate STL files merely by selecting the file on my Mac and pressing the Spacebar for QuickLook, but how are STP files viewed?

Hmmm.... The Mac version doesn't want to let me import STP...

If you cannot create an STL file (which all modern Macs support on the OS level), then perhaps you could post it to Printables, since that site has a built-in viewer, as you can see in this example...

If you cannot create an STL file (which all modern Macs support on the OS level), then perhaps you could post it to Printables, since that site has a built-in viewer, as you can see in this example...

So I've been working on my Mac Effects SE/30 and thought I would share some photos of simple 3D prints I've made.

First up is a semi-transparent gasket for the speaker. I noticed that the Mac-Effects case omits the speaker gasket and I'm assuming that most people don't want to re-use the black rubber gasket from the original case in a clear case. I made a semi-transparent one with flexible TPU and I also have orange glow in the dark TPU that I haven't used yet but I eventually plan to swap this gasket out for that one. I looks nearly identical with the added ability to glow. Additionally I have made replacement black rubber gaskets as shown below in flexible PLA (left over from a 3D airless basketball project) in case there is a need for them in original cases.

Aside from that I also remade the back neck board cover with semi-transparent glow in the dark PLA filament:

I also printed Caver01's brightness wheel in the same semi-transparent glow in the dark PLA filament. I still need to get around to installing it:

Overall I'm pretty happy with the prints so far. I'm also thinking about scanning the original analog board warning cover and laser cutting new clear ones out with the etched in warning labels etc. on a thin flexible acrylic sheet.

First up is a semi-transparent gasket for the speaker. I noticed that the Mac-Effects case omits the speaker gasket and I'm assuming that most people don't want to re-use the black rubber gasket from the original case in a clear case. I made a semi-transparent one with flexible TPU and I also have orange glow in the dark TPU that I haven't used yet but I eventually plan to swap this gasket out for that one. I looks nearly identical with the added ability to glow. Additionally I have made replacement black rubber gaskets as shown below in flexible PLA (left over from a 3D airless basketball project) in case there is a need for them in original cases.

Aside from that I also remade the back neck board cover with semi-transparent glow in the dark PLA filament:

I also printed Caver01's brightness wheel in the same semi-transparent glow in the dark PLA filament. I still need to get around to installing it:

Overall I'm pretty happy with the prints so far. I'm also thinking about scanning the original analog board warning cover and laser cutting new clear ones out with the etched in warning labels etc. on a thin flexible acrylic sheet.

This is pretty fascinating. . .

My easy answer is that since I am participating in this discussion and making adjustments toward progress for each of us, I would hope not to confuse the models.

Now, I have a Printables account too, and I have never really bothered to make my Thingiverse designs have parity with my Printables. But as the sites have evolved, I might try to do more on Printables. The fact is, I started upload my designs to thingiverse before there really was a printables site to use.

That said, when I saw there was a second knob design out there I was curious to see how close it was to my design from a few years ago. I thought maybe it was my design just uploaded to the other site. After pulling them into my CAD program and overlaying, I can say that they are NOT the same, but very very close. It appeared as though a fellow enthusiast used their calipers like I did and reverse-engineered the dimensions—like so many of us do with this old stuff! It was uncanny how similar they were.

That satisfied my curiosity and I moved on. I don’t actually recall the minute variations beyond a slightly different slope to one of the cone-shaped areas. Frankly, it seemed to me that a printed part would work in both our cases just fine. Clearly, we are discovering with resin that tolerances may not be as flexible. I also cannot say whether the printables model has the same depth in the post area, or the same tension on a pot. I didn’t try that model, just looked at it on screen.

This has all been super fun and I feel like my tiny contribution is at least having a moment. My original intention was to fix an SE analog board that was missing the knob. I am glad to see the part having more uses now and look forward to seeing more results.

Sorry for being late to the party!

I don't recall how thoroughly I searched for other models, but I think I opted for my own design because I wanted to justify my Shapr3D license.

I did not realize people were actually using my design as no one has marked it as a 'make' on Printables or provided any feedback. I know my design is a little loose on some boards as I've had to swap out analog boards and know there is some variation. Usually, it still fits enough to "turn". I'd be really interested in hearing if there are modifications I could do to make my model better.

It's funny as I've collected a bunch of parts for my MacEffects clear case build (SE/30 reloaded board, zigzagjoe LCD kit, AustrianMegaTech's acrylic screen cover, blueSCSI, zigzagjoe accelerator, etc) and was watching @JDW 's video on installing the LCD kit when I saw the other video about the dimmer knob and found this thread. I

The resin prints look really cool. Almost enough for me to buy another resin printer and get back into that. It's so messy but it may be worth it.

TPU is a tad more soft and certainly more squishy than PLA and other filament types, but is firm like hard rubber. Are you deliberately using TPU for a speaker gasket because it offers vibration damping and makes the sound from the speaker better? (Which is why you chose it over 100% transparent resin?) Or does the damping from your TPU speaker gasket cause a slight reduction in perceived volume levels?

Separately from that, how well does your bright knob turn relative to the stock knob?

The reason I ask how well the knob turns is because when I did my brightness, knob video, I printed the knob in a variety of plastics and found that 100% transparent resin was the smoothest to the touch, and therefore turned the smoothest as a result. It’s just as good if not better than the stock knob.

Separately from that, how well does your bright knob turn relative to the stock knob?

The reason I ask how well the knob turns is because when I did my brightness, knob video, I printed the knob in a variety of plastics and found that 100% transparent resin was the smoothest to the touch, and therefore turned the smoothest as a result. It’s just as good if not better than the stock knob.

TPU and Flexible PLA feel relatively similar when they are as thin as this since its basically solid infill at 1.5mm thickness. Holding the original gasket and my printed versions doesn't feel too much different to me in terms of texture and flexibility.TPU is a tad more soft and certainly more squishy than PLA and other filament types, but is firm like hard rubber. Are you deliberately using TPU for a speaker gasket because it offers vibration damping and makes the sound from the speaker better? (Which is why you chose it over 100% transparent resin?) Or does the damping from your TPU speaker gasket cause a slight reduction in perceived volume levels?

Separately from that, how well does your bright knob turn relative to the stock knob?

The reason I ask how well the knob turns is because when I did my brightness, knob video, I printed the knob in a variety of plastics and found that 100% transparent resin was the smoothest to the touch, and therefore turned the smoothest as a result. It’s just as good if not better than the stock knob.

I used TPU because I wanted a material with similar flexible properties to the original gasket and for it to be semi-transparent to make the MacEffects speaker still presentable when looking at the Mac. I noticed that a lot of other people's MacEffects builds we're forgoing the gasket and I was concerned that vibrations from the speaker would resonate on the acrylic case without using something between it and the speaker like it was originally designed with. All said and done when playing audio from a stock SE/30 or playing audio from a MacEffects case with the TPU or Flexible PLA gasket; the sounds are exactly the same. Installing the speaker without the rubber gasket may be fine too given that i haven't seen comments about the speaker vibrating annoyingly on the case on other builds. I guess it just comes down to my own personal preference.

As for the resin knob; I would suspect you are correct that it may turn smoother than any FDM printed knob like the one I printed. It really comes down to the layer lines or printed layer height and the texture of the material at the end of the day. The glow in the dark material from Hatchbox has a more coarse feel to it than stock or resin. I'll try to install it next weekend to give a more formal opinion on it. I can also change out my print nozzle from the standard .4mm to a smaller .2mm and reduce the layer height to see I can get it ever smoother, though, resin will always produce the smoothest, most detailed parts.

Thank you for that confirmation....playing audio from a stock SE/30 or playing audio from a MacEffects case with the TPU or Flexible PLA gasket; the sounds are exactly the same.

And just to add one detail... The clear MacEffects speaker looks great in the clear case, but because it is 8Ω and not 63Ω like the stock speaker, the maximum volume level of the clear speaker is lower than the stock speaker. The amplifier can't supply enough power for the low-Ohm speaker and the volume is reduced accordingly. That does not pose any problem. It is just an observation from my own experience with the clear speaker and stock.

I have now done that, it can be viewed on printables (same handle, ArjenCNX)Hmmm.... The Mac version doesn't want to let me import STP...

View attachment 24406

If you cannot create an STL file (which all modern Macs support on the OS level), then perhaps you could post it to Printables, since that site has a built-in viewer, as you can see in this example...

View attachment 24407

Hi Tinkerers, I have made a HDD bracket design for 3D printing, it fits the Colour classic prints well and fits well also. i had a CC with it missing, so now we can print our own.

Printables link: https://www.printables.com/model/1468511-hdd-bracket-macintosh-colour-classic

Printables link: https://www.printables.com/model/1468511-hdd-bracket-macintosh-colour-classic

Attachments

Ok, time to add another tiny update to this thread. . .

My MacEffects clear mouse shell is great, and I even added handmade clear ADB cord. But the button which is a flexing portion of the upper shell has always been very difficult to click. Maybe this is true for others, or maybe it's just the small tolerances of the internals, but in my case, the cross-shaped plunger under the button lands perfectly over the microswitch, but it hangs above about 1mm too high. This requires an extra mm of pressure to bend the button area far enough to contact the switch.

It works. But I find myself struggling to use it. At first, I figured no big deal, since this is a showpiece more than anything, but with Marchintosh approaching I wanted to mess with GlobalTalk for the first time and a clumsy clicker won't do.

So, I whipped up a simple little extension for inside the mouse shell. Actually, it's just a 3.5mm high cylinder that has a 1mm bottom. It sits on the switch and the plunger fits down into it to hold it in place. Easy, and non-invasive, no glue, no modified parts. I printed it in black PLA, popped the mouse open and slipped it in there. STL file attached if anyone feels like they need to do the same.

My MacEffects clear mouse shell is great, and I even added handmade clear ADB cord. But the button which is a flexing portion of the upper shell has always been very difficult to click. Maybe this is true for others, or maybe it's just the small tolerances of the internals, but in my case, the cross-shaped plunger under the button lands perfectly over the microswitch, but it hangs above about 1mm too high. This requires an extra mm of pressure to bend the button area far enough to contact the switch.

It works. But I find myself struggling to use it. At first, I figured no big deal, since this is a showpiece more than anything, but with Marchintosh approaching I wanted to mess with GlobalTalk for the first time and a clumsy clicker won't do.

So, I whipped up a simple little extension for inside the mouse shell. Actually, it's just a 3.5mm high cylinder that has a 1mm bottom. It sits on the switch and the plunger fits down into it to hold it in place. Easy, and non-invasive, no glue, no modified parts. I printed it in black PLA, popped the mouse open and slipped it in there. STL file attached if anyone feels like they need to do the same.

Attachments

The difficulty in clicking my MacEffects clear mouse shell is why I stopped using the shell. Your fix might allow me to use it once again, but JLC3DP refuses to print anything so small, unfortunately. A dab of hot glue may work. I'll need to experiment.

As I recall, this problem arose from the fact that MacEffects found it cheaper to manufacture the mouse top shell as a single piece, rather than multiple pieces like the Apple version housing.

As I recall, this problem arose from the fact that MacEffects found it cheaper to manufacture the mouse top shell as a single piece, rather than multiple pieces like the Apple version housing.

but JLC3DP refuses to print anything so small, unfortunately

How big does the brim have t be again? I printed mine with a brim because I didn’t want it to pop off the print bed it is so tiny. . . but that was slicer generated. I could make one with a .2mm brim built in. This is something you could probably knock together with a straw and baking soda + super glue at the bottom. I mean, it’s such a trivial shape and size, if i just looked around the house I would probably find some cast off piece of trash that would work. Maybe a Lego?

I can’t fault them for that. . .as it also preserves the supreme clarity of the top shell. And maybe not all internal PCBs or microswitches are the same. In any case, the button works beautifully now. I was afraid I would never get used to the stiffer button—especially fatiguing with a drag. The 9-inch CRT isn’t even very much distance to hold a maximum drag—but it was a challenge. This fix has be completely forgetting that. It feels just normal now.As I recall, this problem arose from the fact that MacEffects found it cheaper to manufacture the mouse top shell as a single piece, rather than multiple pieces like the Apple version housing.

Min. size depends on filament, as shown below...How big does the brim have t be again? I printed mine with a brim...

I used black PLA. How about this. I will make a set, staring with a .2mm brim that links together a few different versions, each with thin to thicker bottoms giving you a variety— say .5mm, 1mm, 1.5mm and 2mm giving you some flexibility with feel. 1mm worked fine for me but who knows how much padding you need? Let me knock together a set and I will arrange them in something like a 3x3cm square with a 3cm wall to cover all the dimensions. . . gimme a bit to work this out.

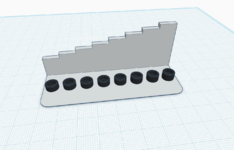

EDIT: The set below has built-in .2mm brim 3cm wide, a stepped wall to push to 3cm high and indicate thick vs. thin bottom, and a set that goes from .25mm through 2mm in quarter mm increments. The ones above 1mm are also taller to ensure they stay put if your button stem really sits farther away.

EDIT: The set below has built-in .2mm brim 3cm wide, a stepped wall to push to 3cm high and indicate thick vs. thin bottom, and a set that goes from .25mm through 2mm in quarter mm increments. The ones above 1mm are also taller to ensure they stay put if your button stem really sits farther away.

Last edited: