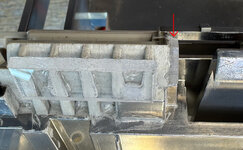

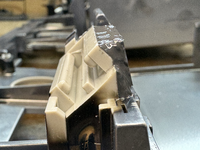

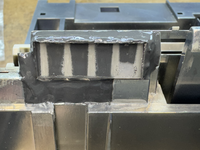

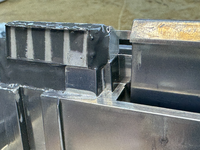

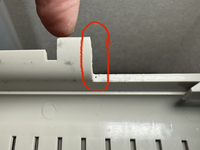

Thank you, these photos clearly illustrate the hinge assembly.

is this a common problem? I’ve not heard of it before.

Very. I have run into it multiple times, and its because the hinges get stiff. 2 reasons. the hinge plastics shrink a bit, causing the springs to shrink and get hard to move, as well as the lubrication turns to putty.

But also those old polycarb plastics are starting to get brittle in general. That frame needs to be replicated into 3D prints so it can be glued together in halves. somehow.

The fingers of those subframes also break and fall apart ,which hold the motherboard in place. I have seen the rear card support plastic thingy also broken apart and seperated into two.

Last edited: