cooling is no option, its a must!

None of the brilliant, outside the boxers at Apple could get that through one particularly thick skull with blinders attached. Hyperfocus on design to the detriment of function is a major failing in a project director. Reality distortion is a multidimensional field, deleterious thought well field affects objects on both sides of the nexus. While he may have been uninvolved (or gone from?) Apple at the time of SE development, design over function culture was firmly in place much to the detriment of product development. Once again, Apple.

Crossflow is the perfect choice for the top corner cooling requirements of the SE/SE/30 bucket.

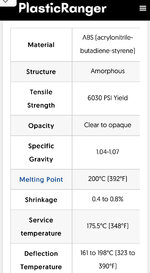

Design charicteristics:

https://catalog.orientalmotor.com/viewitems/mf-series-ac-cross-flow-fans/150mm-ac-cross-flow-fans#

Note the intake overlaps and isolates that one slot in the flyback heat shield, pulling air across the entire bottom slats of the cooling section. Note the four slots in the top fan housing that impart centrifugal (squirrel cage) blower effects

not commonly seen in cross flow design enclosures. They pull airflow straight down from the hot corner above across the vertical rear and top of the heat shield/spreader/radiator surfaces.

Metal side panel helps to direct air from the high pressure fan's exit to the wider, pressure reducing grill boot molded into the back of the SE bucket. Such reduces noise, but apparently not enough for the transition from silent convection (preferably with System Saver) in the Plus to proper cooling in the SE.

Switching from tangential cross flow fan to axial muffin fan retrofit was all kinds of counterproductive I'll posit.

Best case solution would be finding an A/C cross flow fan in a modern, refined, quieter design bodged to the switched A/C feed. Such would reduce stress on the A/B, eliminating power requirements on the 5V rail while cooling far more efficiently, right where it counts.

< /rudimentary understanding of fluid dynamics and package design for computers, ME middle little bro's forte >

edit: placement of that big wide cap in that space appears to smooth the right angle transition of airflow from top of cooling radiator/heat shield?

moar pics: ImageConverter playtime in new worktop Lombard/OS9 and hardware/LCD screen alignment fun =

beans

Far wider angle pull from PSU than muffin fan. Where are hottest PSU Components located, toward rear or front?

Additional cubic available for larger pass thru fan?

--- 63mm housing exit

--- 43mm impeller blades

--- 67mm grill height

__________________________________________________________

Optimal solution for crazy SE/SE/30 expansion configurations would likely be a reloaded, upgraded component A/B per @apm's retina display hack. Such would open up myriad possibilities such as moving the flyback cage forward/down thru optimized printed ductwork on both sides pulling airflow into and out the grill smoothly thru an upgraded Noctua axial fan.

Bonus points available for new sheet metal ductwork replacing stock heat shield/spreader/radiator to eliminate pressure reduction/turbulence induced by backside of OEM unit dating back to the minimally expandable SE's A/B.

@alxlab I hope this isn't too tangential for topic, I did (finally) swing it back onto your printed component track.

Thanks to link to this JDW thread from 2.5 years ago . . .

I've been working on a new video focused on SE and SE/30 fan upgrades over the last month and a half. I don't have any machines with the old squirrel cage fan, but I am aware many SE owners are. I want to add info in my video for those folks. I've searched this forum for "squirrel cage" and...

68kmla.org

. . . I've finally run down Wikipedia articles that explain the differences between the three types of fans used in computers:

en.wikipedia.org

en.wikipedia.org

en.wikipedia.org

Found some great pics. One is a patent drawing for cross-flow fan that lends itself perfectly to an overlay of scale drawing in AI showing Apple's implementation of cooling in the SE. The other shows the wide angle intake a bit more clearly.

@-SE40- has been experimenting with temperature sampling and I think we've come up with a solution for a definitive test of the efficiency of the four configurations available at present:

1 - original cross-flow fan design of the SE

2 - retrofit of tube axial fan to existing case config by

simple rectangular sheet metal duct to later SE and SE/30

3 - upgrade of sheet metal duct to improved, printed cylindrical duct developed by

@alxlab

4 - his circular to rectangular boot duct refinement of first design

Temperature sensor would be affixed to outside of the SE's slot free, solid surface flyback enclosure. That way it would be a constant in the four test cases. I'm thinking that in that position sampling will be done in a static airflow state, unaffected by airflow geometry?

All four configurations would be tested in the same SE so that would be a constant. Has anyone got an SE fitted with Apple's conversion kit. That would make for a fifth test configuration.

@JDW @Scott Baret mentioned the Apple fan conversion kit for the SE in your MLA thread. Have you got an example? If so, you have an original, horizontal neck board "squirrel cage" or access to one, no? If you don't have everything required, I'm sure we can manage to get everything needed for a definitive test routine into your lab? If we can work out details, I think you may have the makings for an interesting video here?

Dunno anything at all about sampling for sound effects of the test configurations. Decibel output count would be just as interesting I think?

Electrical interference from the original design/horizontal neck board was mentioned by Scott as being the reason for the changeover in fan types, not complaints about noise as would be received wisdom (disinformation?) on this subject.

morning musing of the day: thinking a test enclosure isolating intake and exhaust airflow would be very cool here. Using a light weight/low mass fan of some type at the exit might yield interesting results on a meter measuring DC voltage output? Can't think of any other way offhand to test airflow/velocity of the setups?

@Kai Robinson would it be possible to move this tangent to a dedicated hardware topic now? I'd love to get feedback on this insanity. I'll be fleshing out this WIP IP with details and pics of what I've found today. Questions and suggestions from the gang would help me set up illustrations when I can play with this stuff in AI.