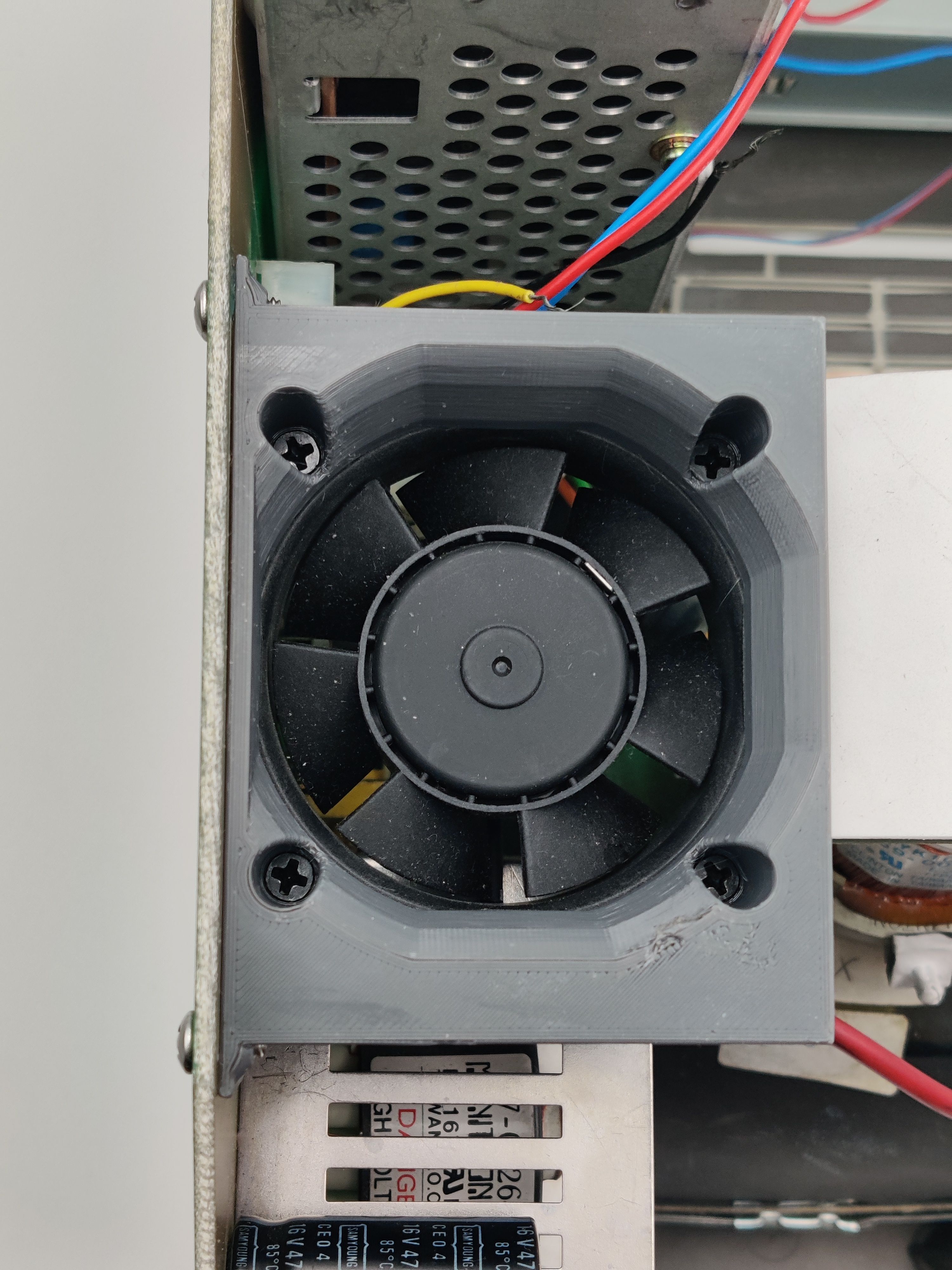

The attitude I took when designing it was to make it at least as good as the original part (the metal bracket) while also making it easy to print with an FDM printer without supports. I also wanted it to be easy to install the fan with to provided mounting screws of the fan without having to buy extra hardware.

I'm familiar with duct work but I'm not sure if I understand 100% what you're trying to say. Do you mean to have more of a conic shape of the intake vs the slight trumpet shape it has now?

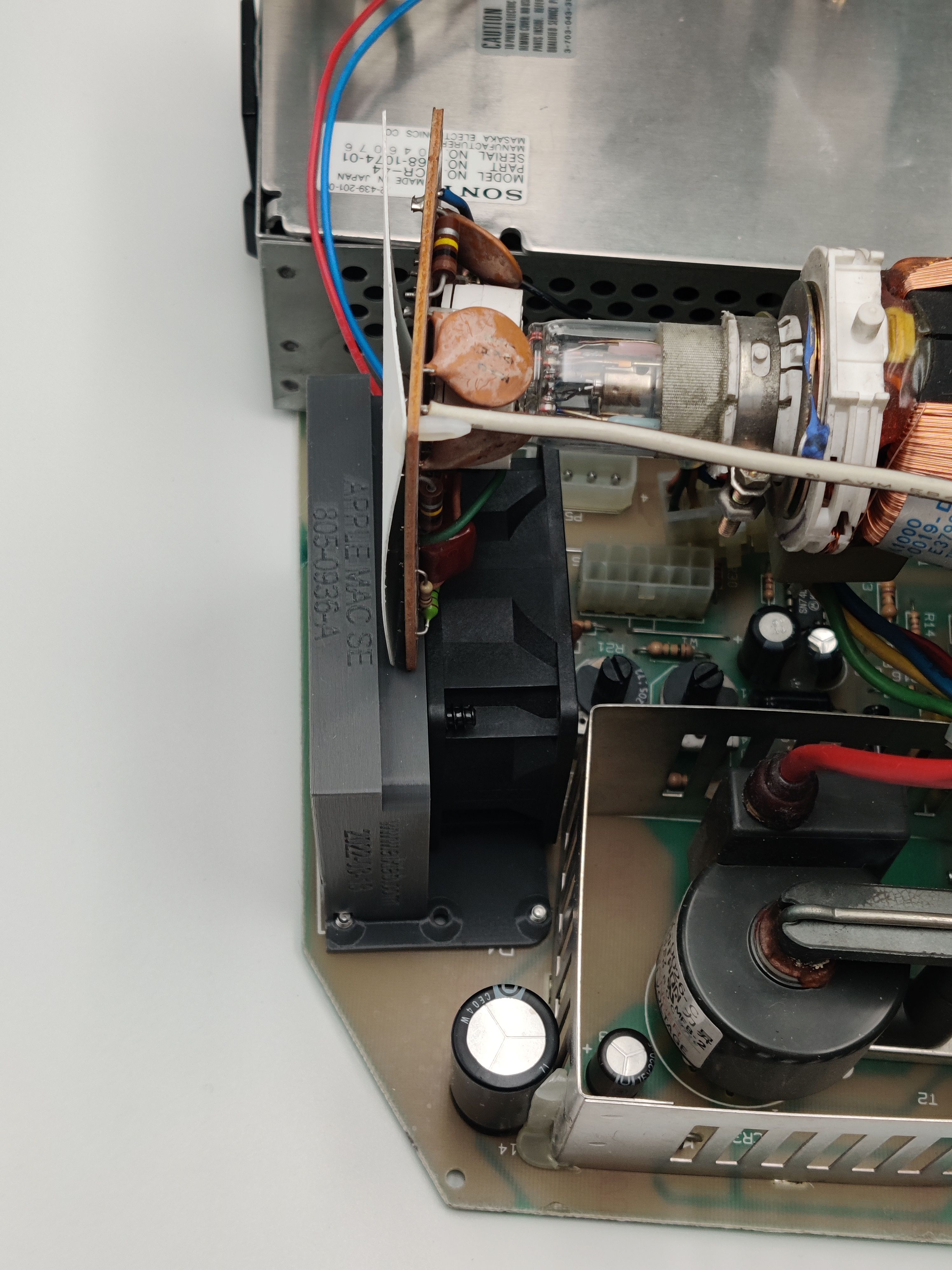

Assuming the gray is an extended view of the outlet? Rectangular exit would extend to meet the corners of the bucket's grill, well past the screw bolt hole locations. From memory, bucket grill is taller on the Y axis and narrower on the X axis than the circular fan outlet?

tube at bottom and planar extension at top should be ignored. Your housing's intake and outlet would take the form of the transition section.

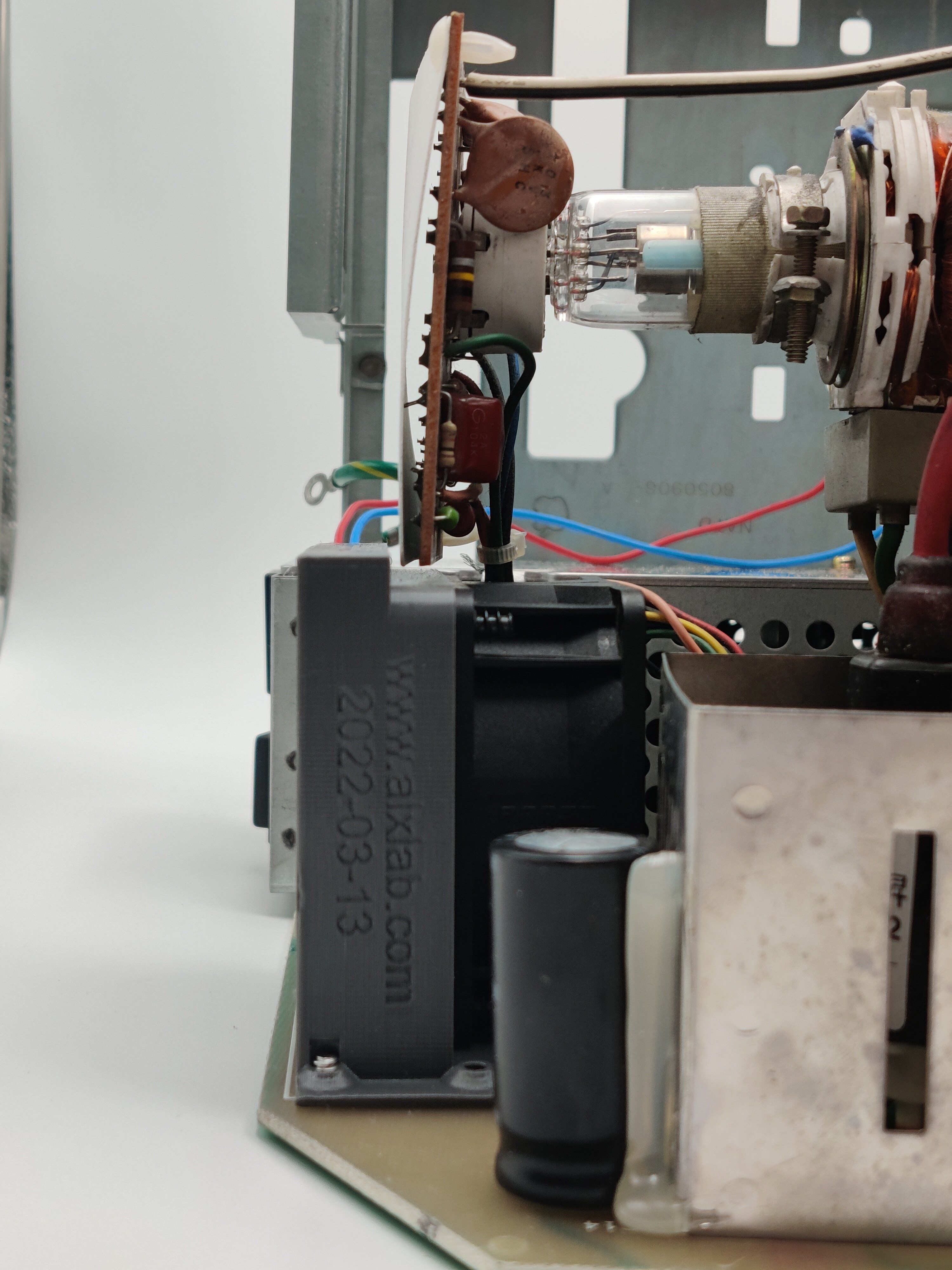

Probably the best advice to reduce noise from the fan would be to just get a modern quiet fan like the Noctua NF-A6x25 FLX.

Better airflow/turbulence/noise reduction applies equally for a quieter fan.

. . . have thought about the possible effects you mentioned from the screw holes. The fan could be screwed in from the back with long screw/bolts but I didn't particularly like the idea requiring people to buy extra bolts to mount the fan on the bracket. In the end I made the conscious decision to prioritize ease of installation and manufacturing. In order to follow my own criteria and to solve the issue, I would probably design some screw caps to cover the holes. I'm not convinced it worth the effort though.

As a fluid dynamics obsessive, designer of multiple dust collection systems, gotta give the nod to your elegant KISS principled plug solution, my compliments.

If I were to improve something it would be regarding the ease of installation . . . once in a lifetime.

What I've inadequately described would require use of drill, tap bit, tap and tap handle. When all you have is a hammer . . . then again, when what you have at hand is more than any sane tinkerer might think imaginable, more simple solutions to such problems would be refinements of the original, tool intensive first take.

As you say, this is once in a (Mac's) lifetime upgrade, so we can probably identify a middle ground. A hangtag bag of appropriate length/gauge hex/phillips headed, self drilling, self tapping sheet metal screws from said Big Box would be more simple, readily available and under $2 in implementation.