The glue can be broken if you put the CPU in the freezer for a while. Then scrape off any residue with a razor.

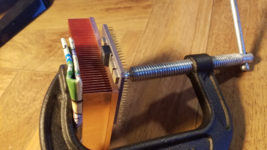

The recommended drying time is 24 hours, so I kept it clamped for that long.

Thermal glue

Thermal paste

The 100mm version should work great on your 040, especially if you can center it better than I could on the LC475.

Thanks for the kind words. They're especially appreciated, coming from someone of your experience.

@YMK

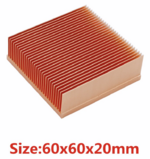

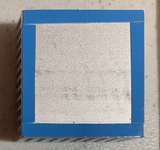

I don't mean to get too off topic here, but your earlier post really got me thinking hard about making the "pure copper heatsink" plunge, so I bought this 60x60x20mm heatsink last night:

The rather large 60mm size will barely fit onto an LC575 motherboard with IIe Card installed. It's 20mm tall too, which means my 40x10mm noctua fan can't be installed on top, which is terribly unfortunate. Another sad fact is that my

40mm Noctua fan would be too tall to stand it its side. As a result, I am mulling the purchase of one or two of these 12V 25x10mm fans, which in theory could be made to stand in their sides, and I guess affixed to some of the motherboard chips with some strong 2-sided tape:

I was able to find the exact glue you use on Amazon Japan here:

But instead of using that glue,

@Mr. Fahrenheit got me thinking about a solution he used recently. Yes, this idea was presented to me in a "private email" but I doubt he'll mind me sharing this "magic secret" to the world. If he does, he can report my post.

(Yes, I'm poking fun at something that happened recently in another thread.)

(Yes, I'm poking fun at something that happened recently in another thread.)

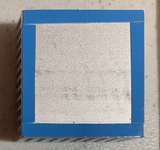

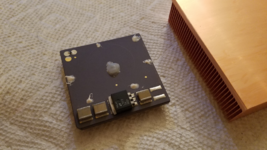

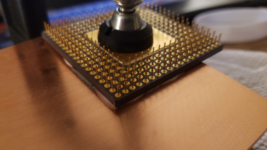

The Magic Cooling Secret™®© that Mr. F. used is to cut 4 thin strips of 2-sided thermal tape and place them all around the heatsink edges like this:

Mr. F. told me he then put a drop of good thermal paste in the middle.

The only thing I don't know is precisely how big of a drop to use, because if you use too little, it won't make for a good thermal transfer. And if your drop of paste is too big, then when you press down, paste will shoot past the tape in places, which will make most or all of the tape not stick as well as it should.

Another consideration is that when I paste something, I tend to use the X-method rather than a Drop because a drop will make a circle while an paste strewn out in the shape of an X will press into a square (which is best in terms of more complete coverage).

Naturally, the purpose of the tape is the same as the purpose of the glue you used -- to hold the heatsink atop the CPU, since it cannot be clipped or screwed down. And because I've got a lot of that blue MADE IN CHINA thermal tape, I am considering that tape instead of the glue. However, on the Amazon USA website, I find additional data on the glue you used...

Thermal conductivity > 1.2W/m-K

I believe the blue MADE IN CHINA thermal tape is a bit less than that, but not a whole lot less, I don't think. So perhaps it wouldn't matter whether one used glue or tape. Most of the heat transfer will come from the good thermal paste in the middle anyway.

The big benefit of the tape for me, other than already having a lot in my inventory, is that there is no drying time required, unlike the glue.

Any thoughts?