Last year, a friend of mine messaged me saying that he had "a bunch of old Apple stuff" for me. Apparently, it had all come out of his parent's basement (a factor that will come into play later). In the pile was a little Macintosh SE.

More specifically, a Macintosh SE FDHD! The FDHD stands for "Floppy Drive, High Density" (or something like that), and can read 1.44 mb floppy disks. Not only does it have a high-capacity floppy drive - it also has a ROM that can take advantage of it, which makes it more special and usable than a typical Macintosh SE. Later versions of this were labeled "Macintosh SuperDrive", which I think is super cool.

Here's what we have to work with. It is extremely dirty, and the front is obviously very, very scratched. At this point, I couldn't tell the condition of the CRT because of all of the dirt. This is by far the worst-looking compact Mac I've ever seen.

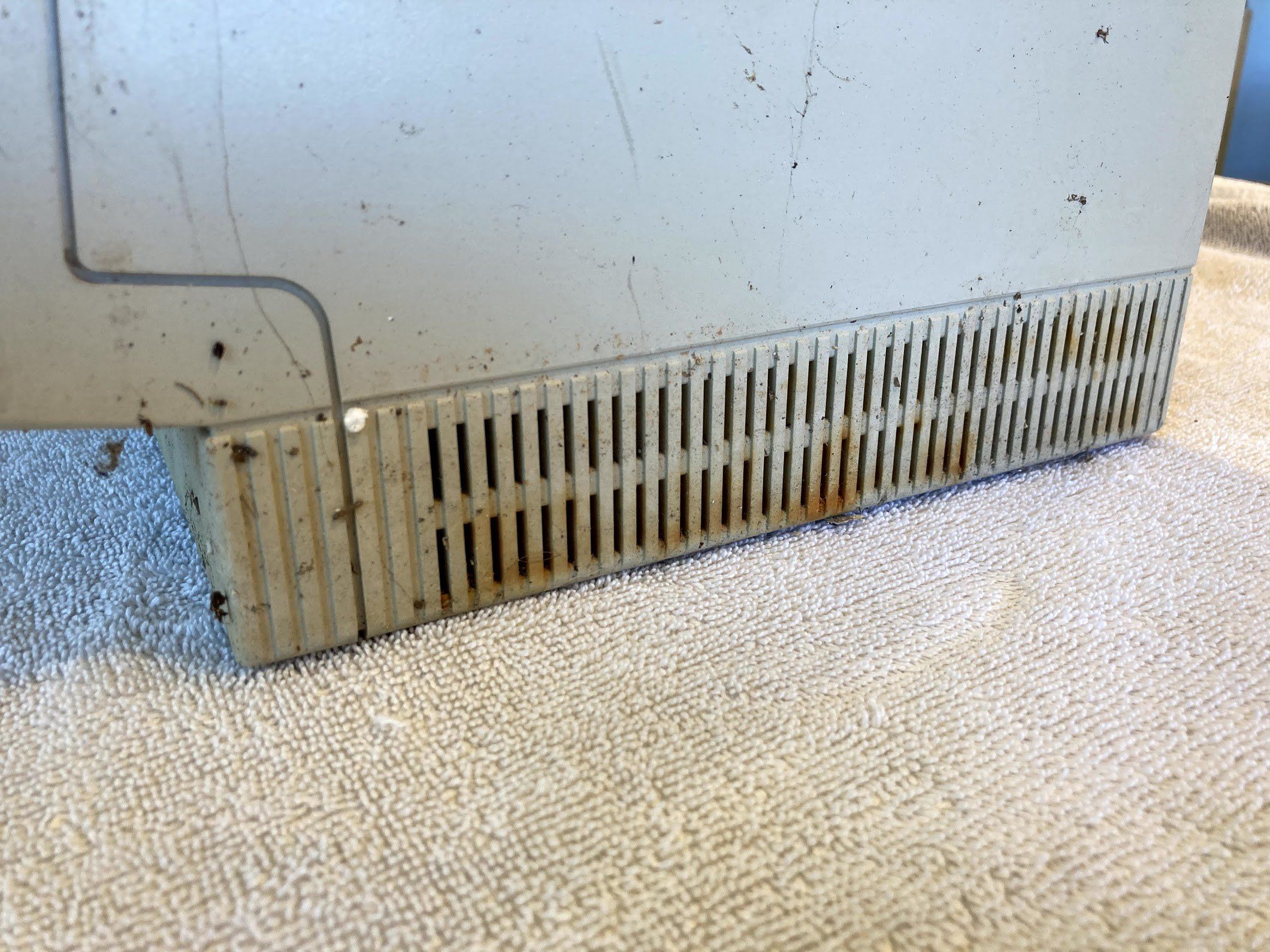

Notice the rust stains around the bottom. Not a good sign.

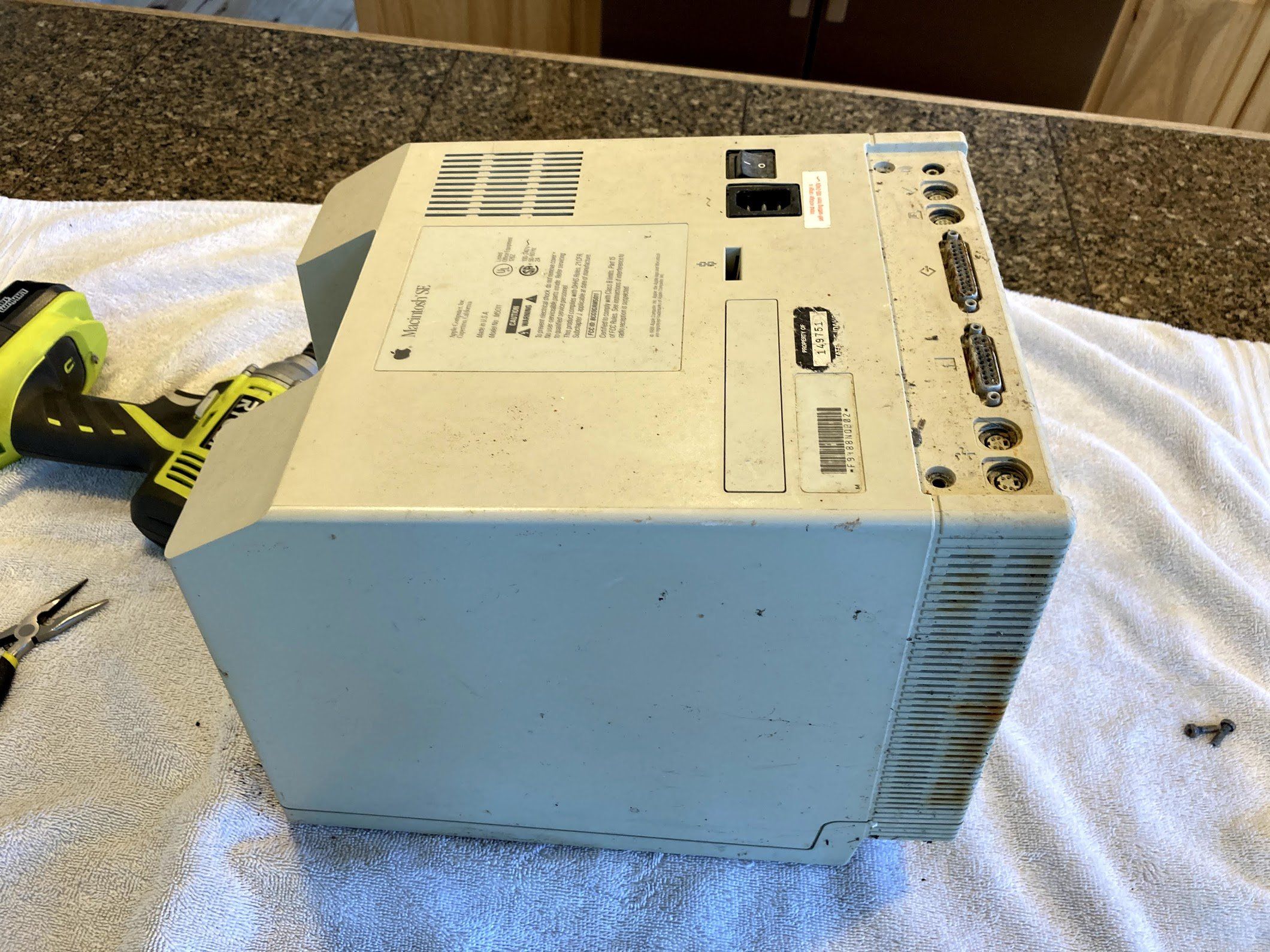

It gets worse. Check out the connectors on the back. At this point, it was becoming very clear to me that there was serious water damage. There's the remains of a "Property of the State of Idaho" asset tag, which is interesting. I've seen 3 or 4 machines with this exact tag.

Expecting the worst, I grabbed my impact driver and broke the screws loose. I was pretty anxious to get it apart.

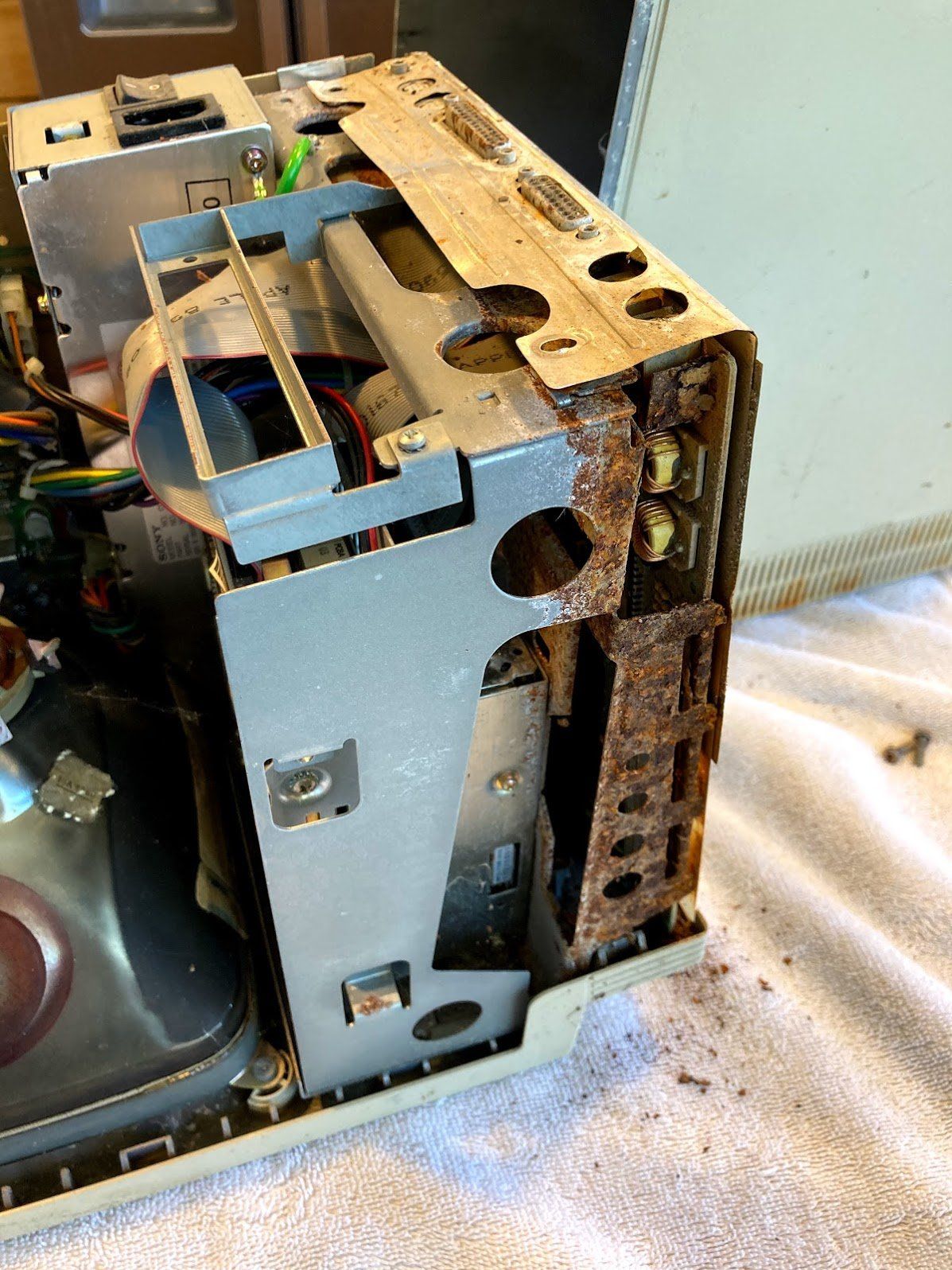

I wiggled the back bucket off, and this is what I was greeted with. Yikes. I seems that this machine sat in some water for awhile. I know it was in a 1940's basement for a couple of decades before coming to me - it seems that there must have been a flood at some point!

At this point, I was thinking, "Well... maybe the CRT could be useful in another machine." Or maybe, "I guess I can salvage the flyback."

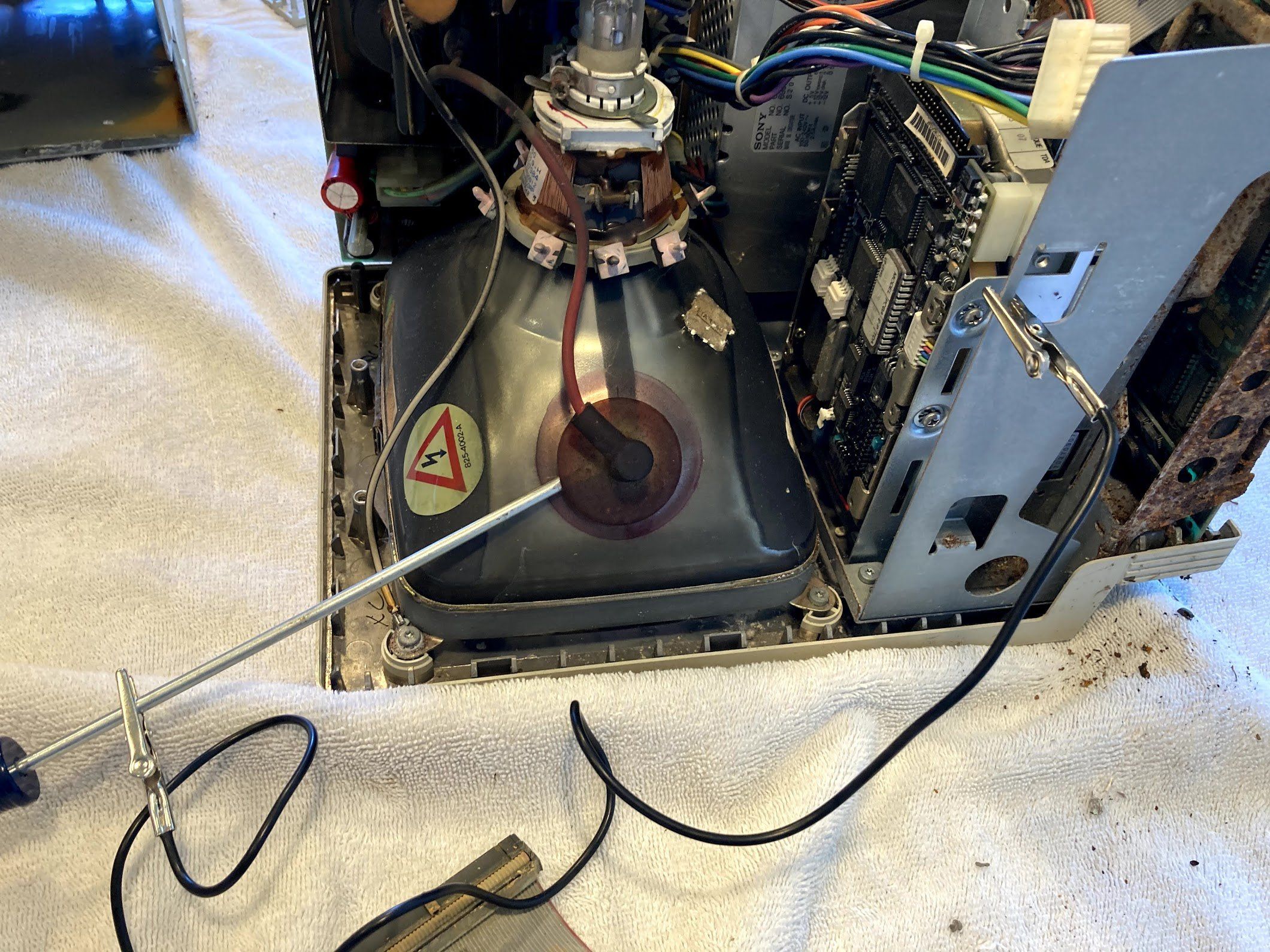

I decided to keep going, and tear it completely down to see what I had to work with. Just to be safe, I followed the CRT discharge procedure of clipping a wire to the chassis and a screwdriver, and sliding the screwdriver under the anode cap. I'm sure this machine hasn't been powered on in ages, but better safe than sorry. I've done this on many compact black-and-white Macs, and I've never heard so much as a "click" from a small arc, but I always do it anyway.

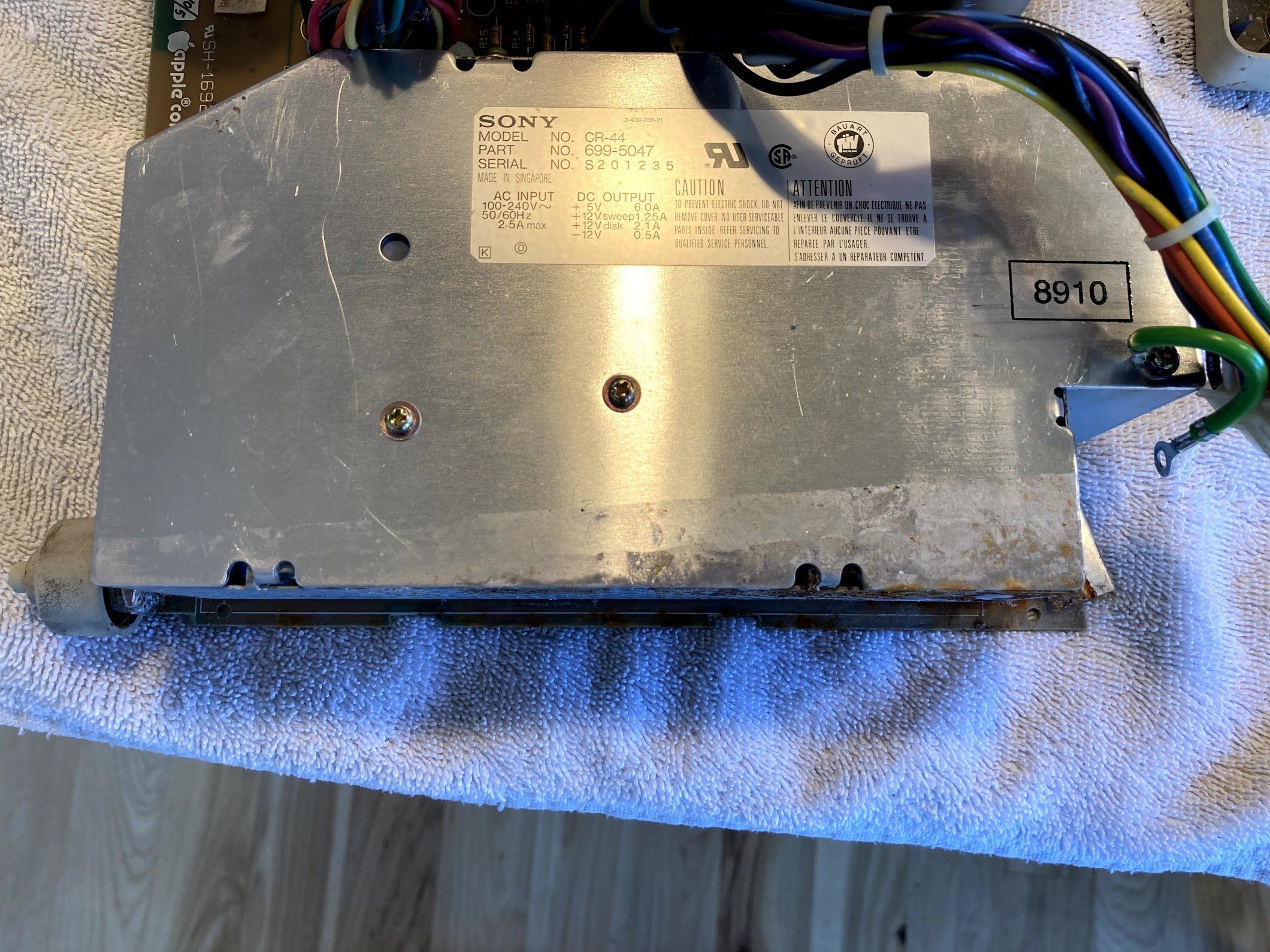

With the CRT discharge out of the way, I could starting tearing it down. But... where to start? The logic board was so rusted in that it wouldn't budge. I decided to unplug the floppy and hard drives first, but those were a struggle. Next, I removed the analog board. Check out the literal "water line". You can see exactly how far up the water came.

With the analog board removed, let's show another photo, just to drive home how totally trashed this machine is. My impact driver was key to getting a lot of the rusted screws loose.

More specifically, a Macintosh SE FDHD! The FDHD stands for "Floppy Drive, High Density" (or something like that), and can read 1.44 mb floppy disks. Not only does it have a high-capacity floppy drive - it also has a ROM that can take advantage of it, which makes it more special and usable than a typical Macintosh SE. Later versions of this were labeled "Macintosh SuperDrive", which I think is super cool.

Here's what we have to work with. It is extremely dirty, and the front is obviously very, very scratched. At this point, I couldn't tell the condition of the CRT because of all of the dirt. This is by far the worst-looking compact Mac I've ever seen.

Notice the rust stains around the bottom. Not a good sign.

It gets worse. Check out the connectors on the back. At this point, it was becoming very clear to me that there was serious water damage. There's the remains of a "Property of the State of Idaho" asset tag, which is interesting. I've seen 3 or 4 machines with this exact tag.

Expecting the worst, I grabbed my impact driver and broke the screws loose. I was pretty anxious to get it apart.

I wiggled the back bucket off, and this is what I was greeted with. Yikes. I seems that this machine sat in some water for awhile. I know it was in a 1940's basement for a couple of decades before coming to me - it seems that there must have been a flood at some point!

At this point, I was thinking, "Well... maybe the CRT could be useful in another machine." Or maybe, "I guess I can salvage the flyback."

I decided to keep going, and tear it completely down to see what I had to work with. Just to be safe, I followed the CRT discharge procedure of clipping a wire to the chassis and a screwdriver, and sliding the screwdriver under the anode cap. I'm sure this machine hasn't been powered on in ages, but better safe than sorry. I've done this on many compact black-and-white Macs, and I've never heard so much as a "click" from a small arc, but I always do it anyway.

With the CRT discharge out of the way, I could starting tearing it down. But... where to start? The logic board was so rusted in that it wouldn't budge. I decided to unplug the floppy and hard drives first, but those were a struggle. Next, I removed the analog board. Check out the literal "water line". You can see exactly how far up the water came.

With the analog board removed, let's show another photo, just to drive home how totally trashed this machine is. My impact driver was key to getting a lot of the rusted screws loose.

Last edited: