I suppose we have now transformed this thread into a 3d printing discussion. . .

This thread seems to have been 3D printing focused since

Post #6.

But for a very logical reason. The topic of the CLEAR CASE from MacEffects naturally leads everyone to ponder the important bits which need to be made clear, such as the brightness knob...

And that brightness knob also pertains to the

@zigzagjoe LCD Retrofit Kit. Doesn't need to be clear for the LCD Kit if you use the stock SE/30 case, and it does not even need to be 3D Printed at all if you use your existing knob. But if you want to retain your old Analog Board in complete condition, you would need a 3D Printed Brightness Knob (what we've been talking about of late), and also a

3D Printed Fan Mount too so you can mount a

Noctua NF-A6x25 fan in it. (See also

Instructions & Screws and the

Forum writeup.)

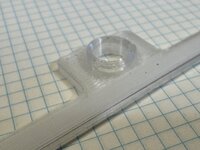

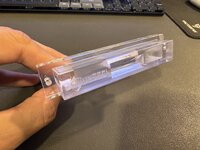

But in terms of a

CLEAR BRIGHTNESS KNOB, the photo above has a semi-transparent appearance similar to what I've had printed at JLC3DP in what they call

"Translucent" 8001 Resin. It's foggy and not 100% clear like a MacEffects SE Clear Case. However, you can also order

"Transparent" 8001 Resin prints...

See

32:56 in my video here to see JLC Translucent vs. Transparent.

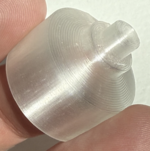

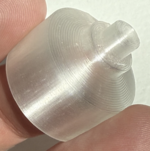

But this brings us back to the topic of the

tiny center piece with a split in the middle, which grabs onto the shaft of the Potentiometer. Will any of the JLC Resin offerings work without cracking? The answer will depend on how much that little center piece (with split in middle) FLEXES when the POT shaft is inserted into it. I know Nylon wouldn't break, but Nylon may actually be too flexible to make a good of the POT shaft!

It's very kind of

@caver01 to have made the "Two in One" STL to get around JLC's frustrating minimum size requirement... FANTASTIC, in fact! But below are my observations about that.

OBSERVATION #1

The only transparent choice you have for FDM printing is TPU Translucent, but TPU is very rubbery and flexible, as far as I know (I've never tried it), and therefore I don't see how it would be suitable for a brightness knob (or would it?)...

OBSERVATION #2

It would seem to me that ABS would be stronger and more durable over time than PLA of the other FDM plastic options, and if that "guess" on my part is true, then you only have BLACK or WHITE as color options...

So I would love to hear discussion about what I said above, and then I can decide what to print for myself at JLC3DP.

And in regards to the

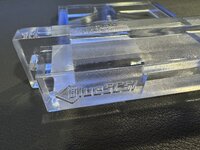

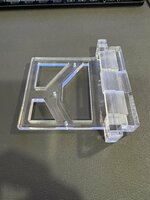

Desk Saver Feet (to allow you to sit an SE or SE/30 with plastic case back OFF on your desk without worry of scratches, in what way is the new

overhange converted to 45° version superior to the original? I printed the original in Nylon and had no issues with it in terms of getting the plastic SE/30 case-back on, but I will admit that I leave the metal shield off...