Ah, no, you don't need anything other than some traces and a single diode to adapt from PowerMac video to VGA. The adapters with switches are only needed for older macs, and even they just have like, two diodes in them, unless you're messing with sync and auto detection. Here is the required circuit:

View attachment 19322

What kind of diode would go between pins 7 and 10 to tell the sense lines it should be VGA? And is it really needed here? I actually rigged up a DB-15 to VGA adapter by simply jumping pins 7 and 10.

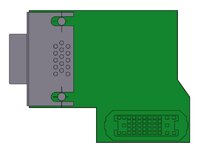

So, if I don't need the diode, it's really easy since DB-15 pins 7 and 10 are pins 9 and 18 on the HDI-45 connector, so I can just drop a trace in between there. Here's the board I have that matches the bodge wire version you see above:

I still want to think about how I could add something that connect to the HDI-45 shielding to stabilize it and likely make for a better ground connection. I assume I should also connect the ground lines to the grounds on the VGA connector? Also, I don't have any way to attach a 3d printed cover (I don't think we will be able to do a case, since it's already going to be a stretch to get the header pins to reach). So with a single screw that can attach a top cover, the underside of the board will be attached with double sided tape and be "invisible" to the user.

Also, please provide PCB design feedback - I've never done this before, Given the simplicity of the wiring, I was able to to it all on the top of the board. Are there advantages to splitting them up between the top and the bottom of the board? Should I try to add more space between the signal traces to lower the chance of interference? I'm also realizing that I wasted a lot of PCB space horizontally. I can shrink that down now that I got all the trace routing organized. I originally thought I'd have to use vias and add a spot for a diode.

Also, because I'm impatient, I went ahead and ordered a batch of 5 from JLCPCB to see if my measurements and layout are reasonable. For $4, why not?!? Obviously, I will update it with feedback from you all, but I'm actually pretty excited this might work!